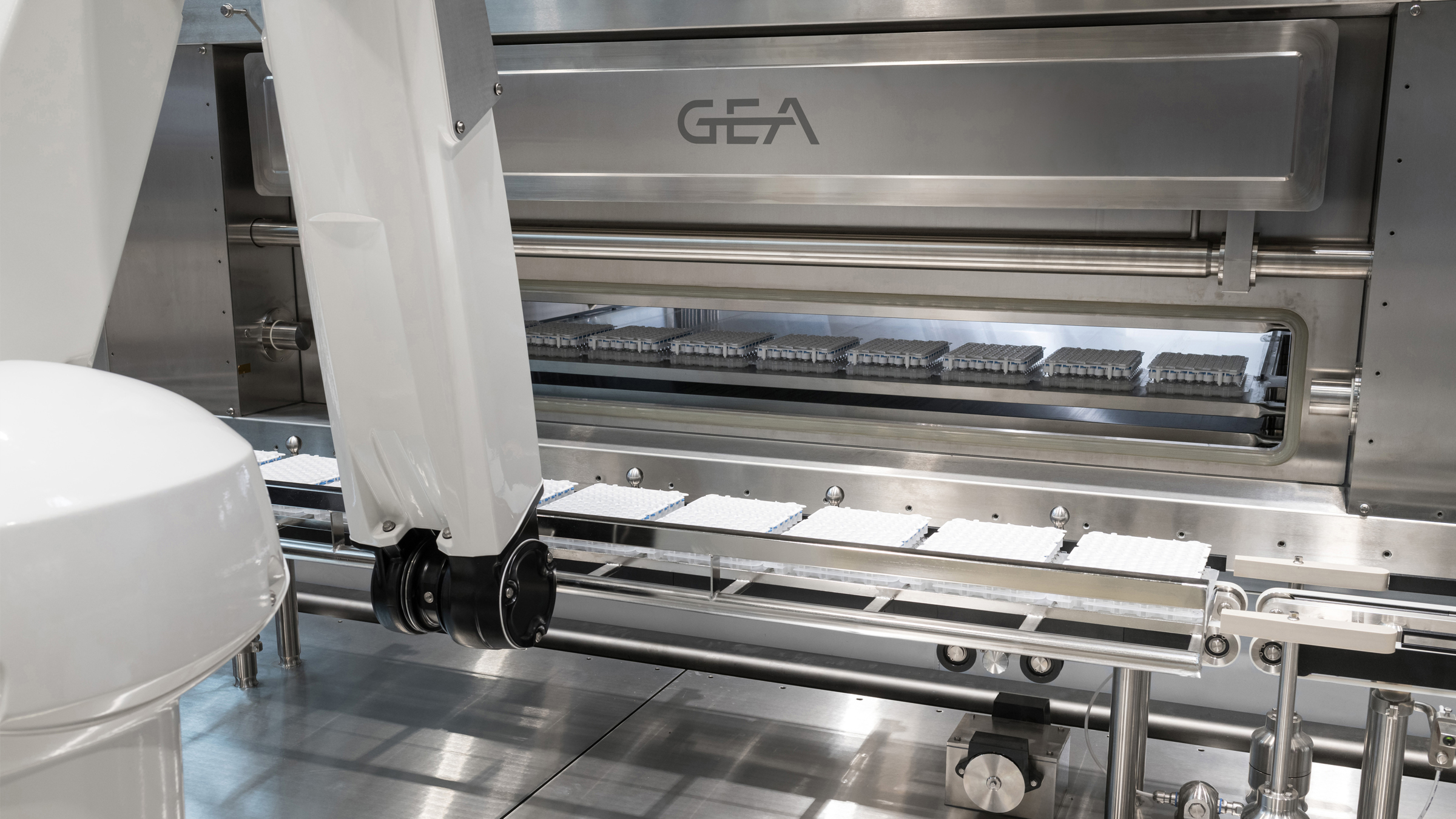

ConsiGma Continuous Manufacturing

Product Description

GEA Group

-

DE

-

2016On CPHI since

-

5000+Employees

Company types

Primary activities

Categories

Specifications

GEA Group

-

DE

-

2016On CPHI since

-

5000+Employees

Company types

Primary activities

More Products from GEA Group (10)

-

Product GEA kytero(R) pharma Separator

Discover what a single-use disk stack separator can bring to your clarifying process: Maximum separation efficiency. Significantly reduced filtration area. Easy operation, saving time and labor. Ensured biocontainment. Get to know GEA kytero(R), the high-yield cell harvesting solution - ready for the next ... -

Product Pharma Separators

GEA pharma separator skids aseptic and pure are energizing the industry with two comprehensive and sophisticated separator lines and one revolutionary new multi-bowl solution. These plug & produce pharma separator skids are breaking new ground in ensuring maximum safety, maximum yield and perfect adaptatio... -

Product Spray Dryer

GEA Niro pharmaceutical spray dryers from R&D to large production scale. Come and discuss your Pharma Spray Drying project with us or learn more about our pharma spray drying technology. Welcome! -

Product Spray drying

GEA Niro Pharma Spray Dryers from R&D to large scale production. Come and discuss your Pharma Spray Drying project with us or learn more about our pharma spray drying technology. Welcome! -

Product GEA Pharma & Healthcare

The Flexibility You Want. The Quality You Need.

Equipped with a wealth of product, customer and market knowledge, you can rely on GEA to deliver end-to-end support for your pharmaceutical manufacturing project. Whether it’s a flexible continuous processing line for an over-the-counter pill, a fully ... -

Product NexGen Press

GEA Pharma & Healthcare has long been recognized as a trusted supplier of cutting- edge tableting technology, with innovations that include

• EXTENDED DWELL TIMES

• a unique DUAL CONTROL system that independently and simultaneously measures and regulates both tablet weight and hardn... -

Product Digital Canary for Better Protection

Modern pharmaceutical equipment is designed to operate in a completely dust-tight manner; but, it’s absolutely critical to be fully prepared for worst-case scenarios, such as an unexpected containment breach. As the level of potentially dangerous airborne particles is often far below what ... -

Product LYOVAC ECO Mode

LYOVAC ECO Mode: a solution for tomorrow

With a focus on saving both energy and media, GEA’s new LYOVAC® ECO Mode combines dynamic condenser temperature control and mushroom (chamber/condenser) valve regulation to optimize the lyophilization process.

Our new algorithm changes the set point ... -

Product Pharmaceutical Spray Drying

GEA, has been a pioneer in all aspects of spray drying and has contracted and installed more than 10,000 plants worldwide. We have a a long history of serving the pharmaceutical industry, and our supply includes spray dryers for R&D and product development, as well as equipment and complete lines for c... -

Product GEA XStream lab homogenizer

The new lab unit is available in two models: XStream Lab Homogenizer 1000 and 2000 with different options according to specific requirements and Pharma execution:

• cGMP, CFR21 and GAMP certifications with data recorder

• Frequency converter for variable flow-rate (external)

• Min...

GEA Group resources (5)

-

News Advancing the safety and security of pharmaceutical freeze drying with automation

Since 1989, GEA has been at the forefront of ALUS technology. Having designed, patented, manufactured and made continuous improvements to the ALUS system, it’s the first company to develop this technology, create fixed systems (conveyor-pusher systems) and subsequently integrate them into an isolator. The company’s 35-plus years of experience have resulted in a validated base of more than 350 production-scale ALUS systems being installed worldwide, seven patents and an ongoing programme of improvements to enhance both handling and maintenance. But that’s far from the end of the story. There’s more to come and next-generation ALUS products are already being developed. Watch this space. -

News Coating coin-shaped cores: a downstream technology solution to reduce tablet capping

When it comes to reducing the incidence of tablet capping or delamination, the use of flat-faced or coin-shaped cores offers several benefits compared with biconvex ones. Previously, however, coating these forms has been problematic. Novel technology from GEA Pharma & Healthcare now provides a solution. -

News Improving the sustainability of pharmaceutical freeze drying

Freeze dryers are typically associated with high levels of energy consumption; to counteract this issue, GEA Pharma & Healthcare has introduced the LYOVAC ECO Mode, which optimizes the process with dynamic condenser temperature control and mushroom valve regulation. -

News Forging industry partnerships to accelerate the uptake of continuous pharmaceutical manufacturing

GEA and its partners are leading the way toward smaller, more flexible continuous processing technologies that are transforming the future of pharmaceutical development and manufacturing. -

News Uniting innovation and sustainability in pharma

GEA directs its focus toward the juncture of sustainability and innovation, igniting positive transformation across our organization and the expansive pharmaceutical sector.

Sustainability in pharmaceuticals encompasses layers of significance. Central to this is drug manufacturing, which carries substantial environmental implications, spanning resource usage, waste generation, and emissions entailed in production, packaging, and distribution. The collective adoption of eco-conscious practices within the life sciences sector serves as a collaborative effort to confront challenges such as pollution, climate change, and the depletion of vital resources.

Embedded in this landscape is the critical challenge of resource conservation. Given the extensive raw materials, energy, and water consumed by pharmaceutical processes, the adoption of sustainable practices to curtail the use of invaluable natural resources ...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance