Advancing the safety and security of pharmaceutical freeze drying with automation

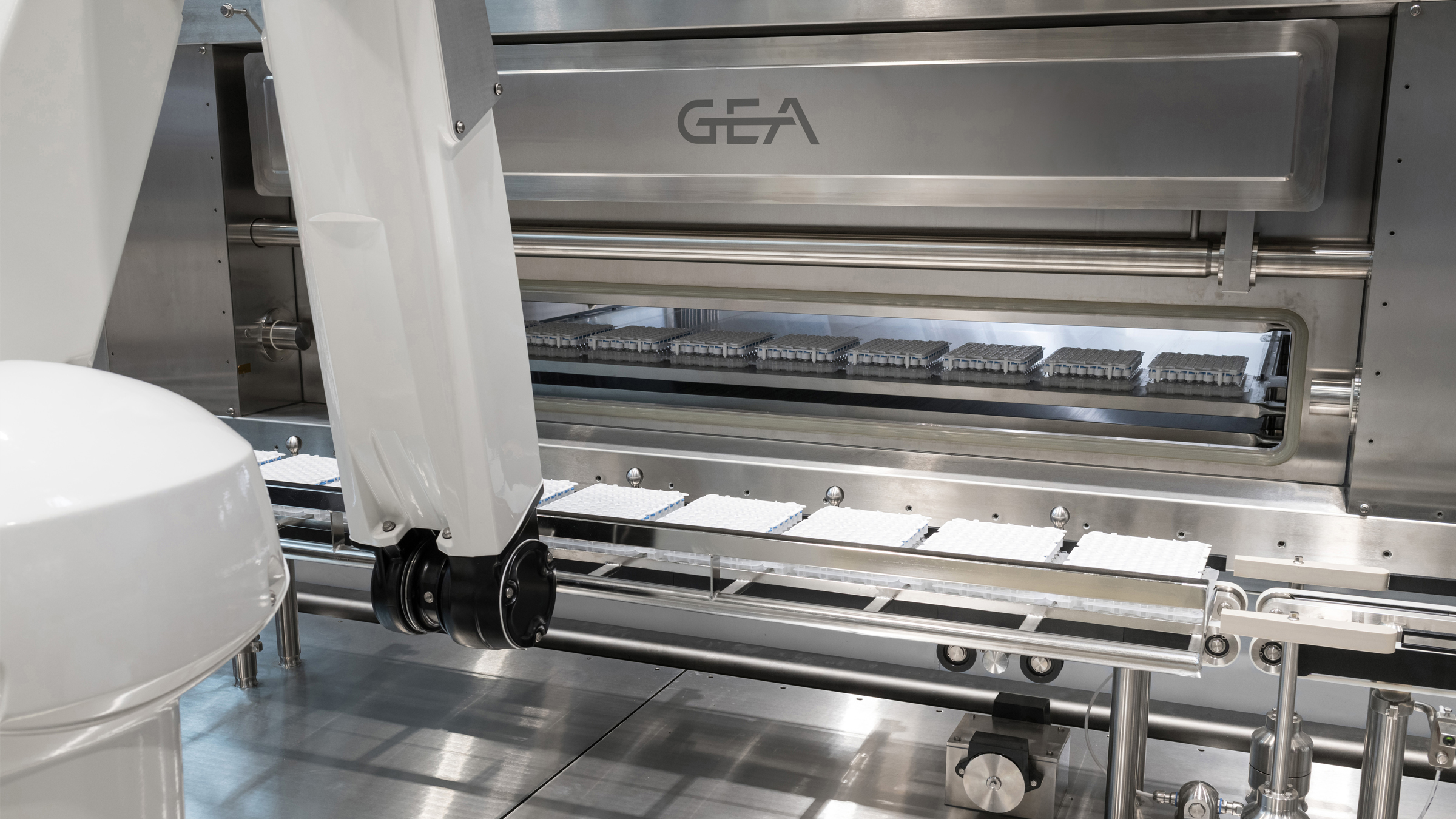

Since 1989, GEA has been at the forefront of ALUS technology. Having designed, patented, manufactured and made continuous improvements to the ALUS system, it’s the first company to develop this technology, create fixed systems (conveyor-pusher systems) and subsequently integrate them into an isolator. The company’s 35-plus years of experience have resulted in a validated base of more than 350 production-scale ALUS systems being installed worldwide, seven patents and an ongoing programme of improvements to enhance both handling and maintenance. But that’s far from the end of the story. There’s more to come and next-generation ALUS products are already being developed. Watch this space.

This year marks the 35th anniversary of GEA's pioneering Automatic Loading and Unloading Systems (ALUS) technology, which has significantly transformed the pharmaceutical production process.

From its earliest applications in the stabilization of blood plasma, freeze drying has been in use in the life science industries for decades. During this period, the freeze dryer — or lyophilizer — has evolved from a simple device for vacuum drying at low temperature to an extremely sophisticated integrated system. Current options combine several processes to ensure that a product is consistently delivered to technical and biological specifications while also considering economic, safety and environmental issues. In the dynamic landscape of pharmaceutical manufacturing, automating this process has played a pivotal role in terms of ensuring compliance with stringent health and supervisory regulations.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance