Improving the sustainability of pharmaceutical freeze drying

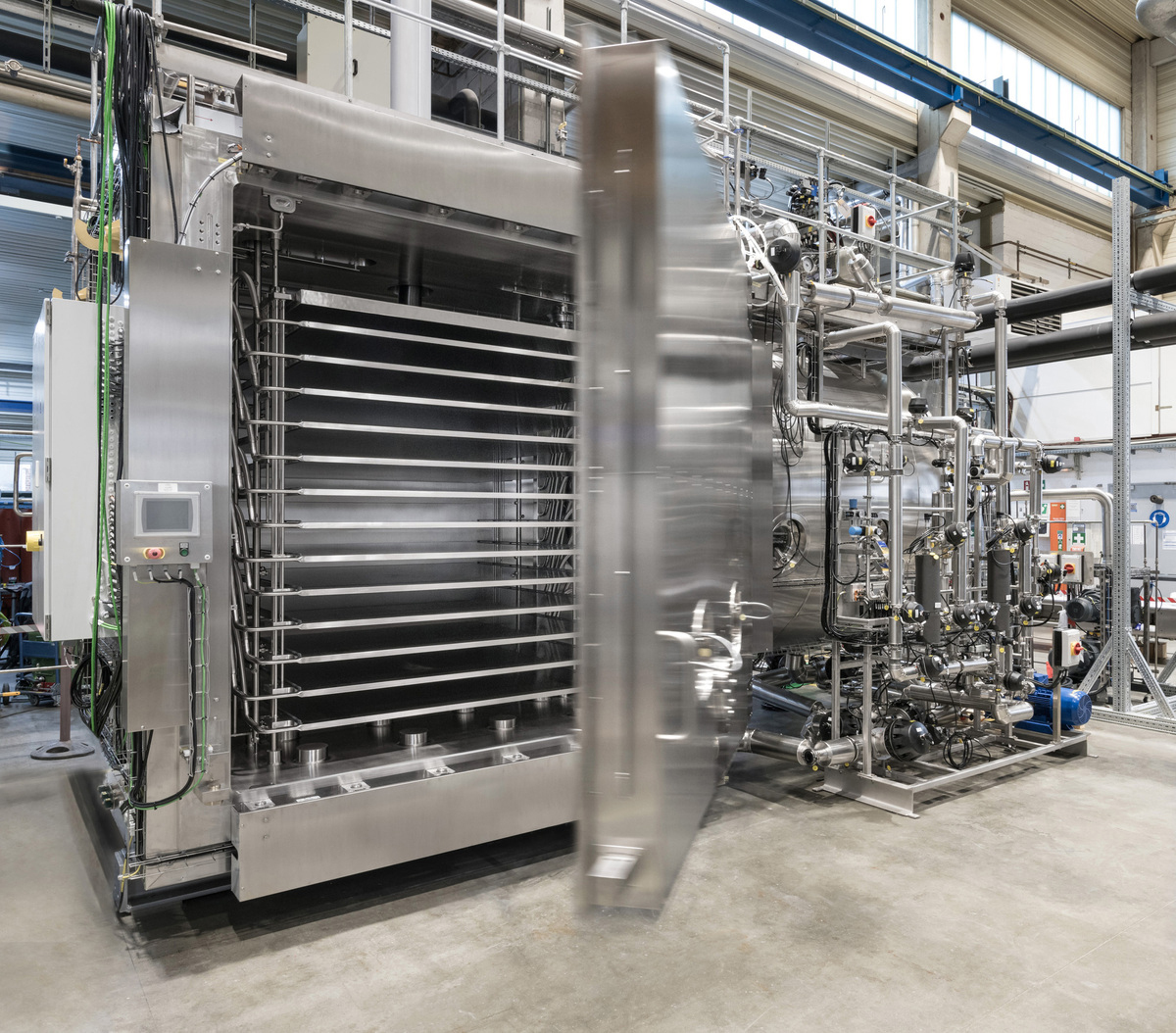

Freeze dryers are typically associated with high levels of energy consumption; to counteract this issue, GEA Pharma & Healthcare has introduced the LYOVAC ECO Mode, which optimizes the process with dynamic condenser temperature control and mushroom valve regulation.

GEA fully understands that product and process innovation must improve the sustainability of its equipment, particularly regarding emissions derived from steam, electricity and refrigerant leakage.

Operationally, the power needed to drive a freeze dryer’s refrigeration system accounts for more than 60% of its total energy consumption. In addition, long process durations exacerbate energy consumption and it’s known that vacuum systems and their control are extremely inefficient.

As Thomas Beutler, Senior Director of Lyophilization Technology Management, notes: “Using a nitrogen bleed to regulate the chamber pressure is like driving a car at full throttle and controlling its speed with the handbrake!”

Some solutions are already available to help users and operators to achieve their sustainability goals, such as the LYOAIR® cooling system, which uses natural refrigerants, and novel concepts such as microwave-assisted and atmospheric spray freeze-drying.

But, when it comes to process optimization in the world of lyophilization, there’s more to come...

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance