Technoflex

About Technoflex

Certifications

Categories

-

FR

-

2015On CPHI since

-

4Certificates

-

250 - 499Employees

Company types

Primary activities

Meet us at

CPHI Japan 2025

East Halls 4, 5 & 6, Tokyo Big Sight, Tokyo, Japan

09 Apr 2025 – 11 Apr 2025

CPHI & PMEC China 2025

Shanghai New International Expo Center

24 Jun 2025 - 26 Jun 2025

CPHI South East Asia 2025

MITEC, Kuala Lumpur, Malaysia

16 Jul 2025 - 18 Jul 2025

CPHI Frankfurt 2025

Messe, Frankfurt

28 Oct 2025 - 30 Oct 2025

Products from Technoflex (5)

-

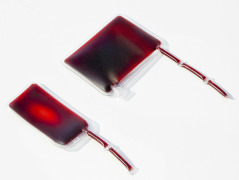

Product Biocell® - High Quality Flexible Bags Ensuring Bioproducts Preservation

EVA bags can be used for a variety of applications such as blood derivatives, vaccines,biopharmaceuticals and biosimilars. The material used ensures the bag stays flexible when plasma is frozen, at temperatures below 80°C. • Volumes from 50 ml up to 3 000ml, • Freezing temperatures down to 80°C... -

Product Cryocell® Flexible Bags - Make cryopreservation safer

Cryocell® are dedicated to the cryopreservation of tissue and stem cells. • Freezing temperatures between -80° and -196°C, • Production dedicated in specific biotech area, • USP Class VI & ISO 10993 compliance, • EVA twist-off or membrane tube port welded and ISO compliant with ISO Spike... -

Product Dual-Mix® Flexible Bags - Innovative Error-free System for Drug Reconstitution

Technoflex has developed Dual-Mix ®, an innovative primary packaging which meets three challenges: storing the medicine to be reconstituted (powder or lyophilizates) and its diluent, making its reconstitution secure and ensuring the safety of healthcare staff and the patient. • Ready-to-Use • Peel... -

Product Inerta® Flexible Bags - Guaranteeing Drug Preservation Until Administration

The proven and recognized chemical inertia of the Inerta® polypropylene bags simplifies the packaging of drug solutions in a reliable, tried and tested container. Inerta® bags* are fully compliant with the requirements of European and American pharmaceutical regulations. They meet customer require... -

Product SafeCell® Flexible Bags - Cutting-edge Design for Cell Culture

The SafeCell® range is made of Fluorinated Ethylene Propylene (FEP) and provides the response to the demands of ex-vivo cell culture. FEP is chemically and biologically inert and perfectly adapted to cell suspension culture. Its antiadhesive properties allow cells to float freely and develop in their...

Technoflex Resources (1)

-

Video Technoflex, the IV drug delivery expert

For more than 40 years, Technoflex has been working with all the major pharmaceutical laboratories. The many improvements and innovations introduced in existing packaging have contributed to facilitating manipulations of injectable products by caregivers.

Today, biotherapies and cell therapy are opening up perspectives for customized medicine where the choice of the primary packaging is crucial.

Every day, Technoflex brings all its expertise in the healthcare field to bear in order to enable today’s alliance of therapeutic research and the design of innovative packaging to create tomorrow’s treatments.

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance