ROMMELAG AG

About ROMMELAG AG

Certifications

Categories

-

CH

-

2018On CPHI since

-

2Certificates

-

1000 - 4999Employees

Company types

Primary activities

Meet us at

CPHI Japan 2025

East Halls 4, 5 & 6, Tokyo Big Sight, Tokyo, Japan

09 Apr 2025 – 11 Apr 2025

CPHI South East Asia 2025

MITEC, Kuala Lumpur, Malaysia

16 Jul 2025 - 18 Jul 2025

Products from ROMMELAG AG (4)

-

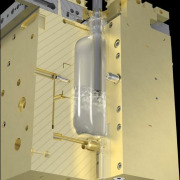

Product Aseptic Blow-Fill-Seal packaging machine for the production of bottles - bp 321

IV solutions are basic life-saving drugs that are as wide ranging as their applications, including hydration agents, chemotherapy, pain management, antibiotics, plasma volume expanders, total parenteral nutrition, and many more. The blow-fill-seal process offers the highest level of sterility assur... -

Product Aseptic Blow-Fill-Seal packaging machines for the production of ampoules

Not only do bottelpack machines offer cost-effective eye drop production under highly sterile conditions, this method of aseptic filling and packaging also enables flexible container design, a reduced environmental footprint, and preservative-free formulas. Because single-use (also known as unit-... -

Product high capacity aseptic filling - bp 460

When it comes to high capacity production of SVP containers at the lowest unit costs, our machine type bp 460 is the first choice. Regulatory bodies consider BFS as advanced aseptic manufacturing – only one operator is required to supervise the process. Multiple containers are formed, filled and ... -

Product packaging of pharmaceuticals and cosmetics

Our bottelpack aseptic packaging systems are considered advanced aseptic filling by regulatory authorities. The BFS containers are formed from plastic polymer material in an automated process, filled and hermetically sealed. With the packaging of sterile liquids (e.g. eye drops, infusion solution, ...

ROMMELAG AG Resources (7)

-

Video Next Level BFS

ADVANCED ASEPTIC AMPOULE FILLING: BFS Closed Parison Technology is flexibility on a small footprint, combined with highest sterility assurance, which fullfils the new Annex 1 EU GMP guideline. -

Brochure Blow-Fill-Seal Solutions

If it says “bottelpack” on it, you can rely on the uncompromisingly good quality offered by the inventor of blow-fill-seal technology. With a combination of German engineering expertise and Swiss precision, we make sure that your machine only ever produces precisely what you defined – from the smallest ampoule to the largest container. And that’s a promise! Rommelag’s bottelpack machines are capable of manufacturing up to 34,000 containers an hour in a wide variety of forms and plastic blends. Classic container volumes range from less than 0.1 ml to more than 1,000 ml. ml. Sounds good, you say? That’s what our customers say, too, and they enjoy the flexibility, precision, reliability, and virtually unlimited scope of BFS technology. -

Video Blow-Fill-Seal Technology Intro

This video gives you an idea of the unique BFS process and and its applications.

-

Video Rommelag Pharma Platform

The Rommelag Pharma Platform, RPP, is the basis for digitalizing your bottelpack BFS aseptic filling system for the next generation of pharmaceutical manufacturing.

RPP comes with a detailed information model, granting access to a wide array of possibilities for leveraging data and integrating third-party tools. By networking your bottelpack machines with your shop floor, office, and the Rommelag Service Center, RPP helps you streamline your production and maintenance processes for better decision making and real-time monitoring.

With RPP, your bottelpack machine acts as the conduit for connecting your shop floor to Rommelag’s service and maintenance cloud. The power of RPP lies at the intersection of four key digital components that enable enhanced production, servicing, and recordkeeping for pharma processes

-

Brochure BFS Ampoules for Skin Care and Anti-ageing

Cosmeceuticals are high-end products for skin care and anti-aging. Blow-Fill-Seal ampoules are innovative packaging comparable to those used in pharmaceutical products.

The soft ampoules are made of 100% recyclable materials and are manufactured in pharmaceutical quality. This could be a decisive USP in the marketing of your cosmetic products in today's world.

The bottelpack Blow-Fill-Seal technology combines cost-efficient production and quick availability of a large quantity of product units.With our sterile single-dose ampoules we offer the consumer a convenience solution for daily use and on the go.Single-dose ampoules make it possible to dispense without preservatives and thus reduce possible side effects.The BFS technology we invented has been tried and tested in the pharmaceutical industry for many decades and is considered one of the safest aseptic filling methods worldwide. This allows us to guarantee a process-safe ... -

Video Blow-Fill-Seal (BFS) Technology

BFS Process- Features & Benefits Automated, continuous process removes human element, greatly reducing risk of sterility failuresMinimizes machinery footprint and eliminates costly processes of container inventory, cleaning, and sterilizing, as well as separate filling, capping, and transport operationsAny container you can dream: canisters, bottles, tubes, ampoules, drop bottles, bellows, and portion packaging with filling volumes range from 0.04 ml to 10 litersOutput volumes up to 34,000 pieces per hourA safe, flexible, and shatterproof alternative to glass containers

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance