The

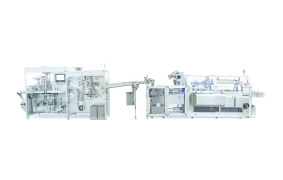

Siebler HM 1-230 vertical heat-sealing machine packs pharmaceutical solids

in air, light and moisture-tight strip packaging. Configured with eight-lane

product feeding, this compact, balcony style machine processes up to 3200

tablets or 1800 capsules per minute. Reproducible sealing parameters and

bespoke sealing patterns provide very high sealing quality. The rotary sealing

system features thin-walled, detachable format sets, which heat up rapidly and

guarantee extremely precise temperature distribution on the sealing surfaces.

Multiple heaters and integral temperature sensors make the process even more

reliable. Furthermore, the design of the sealing tools ensures optimal reaction

times when checking the temperature tolerances.

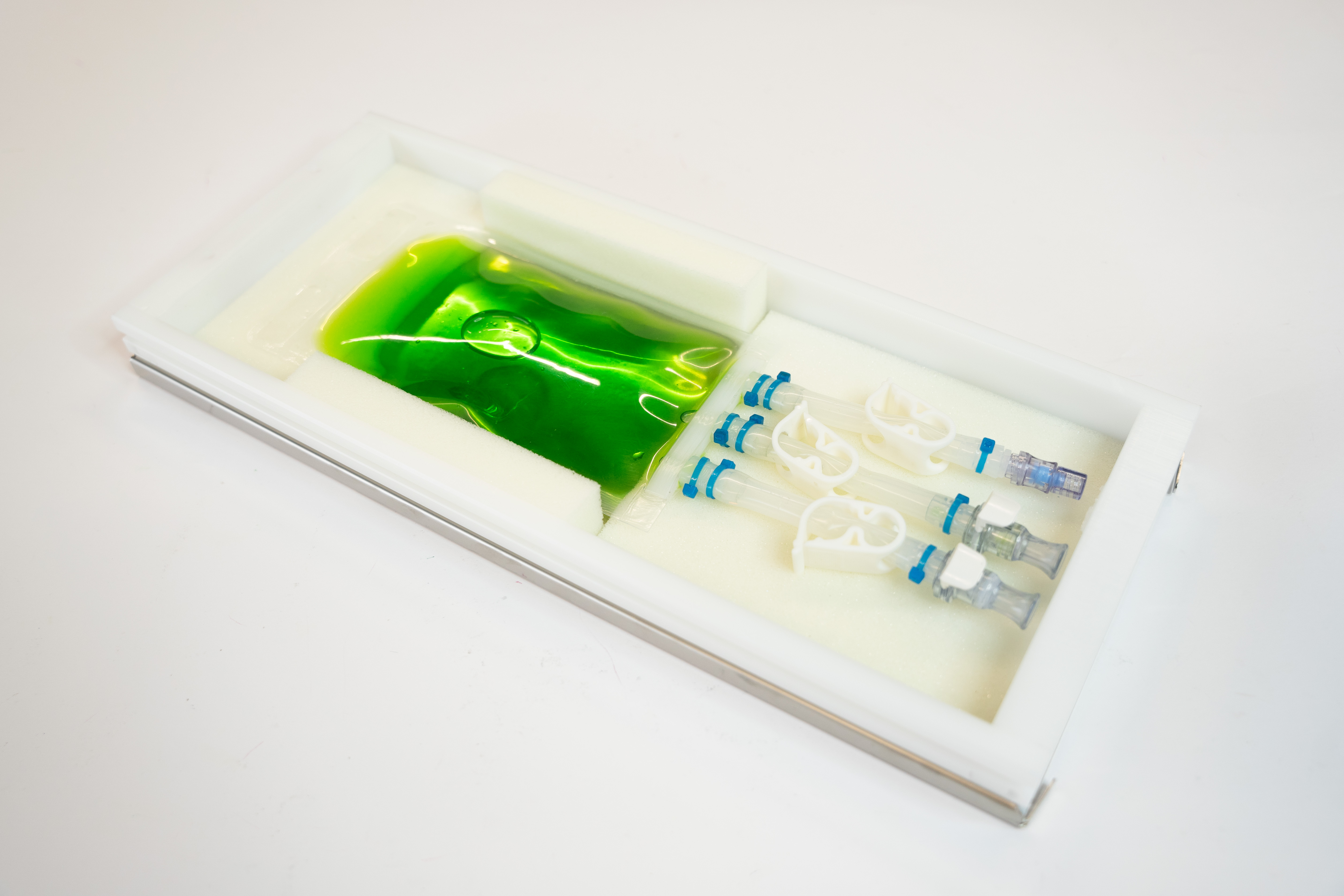

For

the first time, strip packaging in different geometries can be manufactured if

the customer so wishes. Round or star-shaped packaging is now possible, too, in

addition to the standard rectangular forms. Siebler also offers highly flexible

solutions for transferring the strips to a downstream Romaco Promatic cartoner.

And thanks to the Romaco Siebler FlexTrans servo-driven transfer station,

de-stacking is almost completely independent of specific formats. The system

can thus be adapted quickly and easily to different strip layouts, pack sizes

and stack heights. The cGMP compliant design of the Siebler HM 1-230 is ideal

for both small to medium batch sizes and so-called blockbuster products.

.jpg)

.jpg)

-comp306932.png)

-comp267646.png)

-comp245730.png)