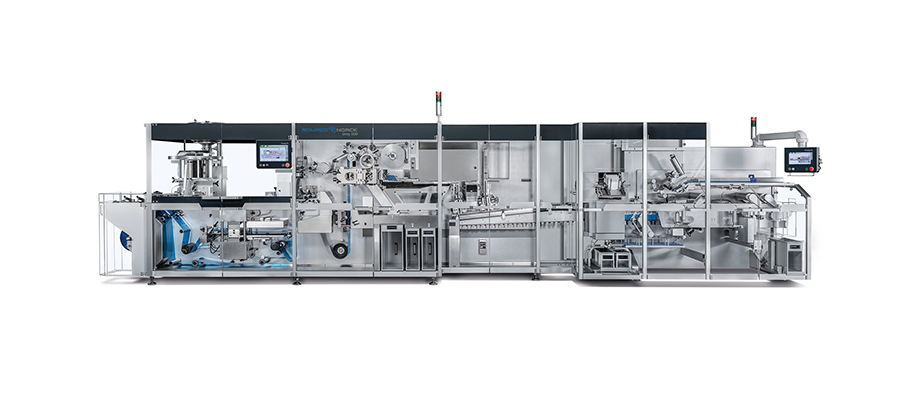

Romaco’s fully integrated Noack

Unity 500 blister packaging line in monobloc design is a turnkey solution

for packing pharmaceutical solids. Thanks to its extremely compact design, this

primary packaging unit takes up very little space in the cleanroom where the

open product is processed. The packaging machine’s designers positioned the

individual stations – such as forming, feeding, sealing, coding, perforating

and die-cutting – very close together for this reason.

The result is a blister technology that

is up among the leaders in the mid-performance class in terms of both space use

and output, with a remarkable 500 blisters and 400 cartons per minute. The

intuitive HMI panel, with its short learning curve, is a further advantage of

the user-friendly blister line. The highly automated system concept is

self-explanatory and requires no specialist expertise on the part of the

machine operator.

Since the Romaco Noack Unity 500 can be

equipped with various feeding units, the technology can be used very flexibly

to process pharmaceutical solids in numerous different shapes and sizes. If

required, the blister line can even be configured for packing multi-phase

preparations.

Equipped

with Romaco Noack’s patented QuickFeed feeding system, the Unity 500

speeds up product changes because the complete module can be replaced in a few

simple steps. A considerable time saving is thus possible by providing a second

unit. The optimal access to all components moreover simplifies cleaning of the

blister line. Reproducible format parameters and QuickAdjust, the automatic

station control system, simultaneously reduce the run-in times to almost zero.

After the primary packaging is done, the finished blisters are passed directly

to the intermittent motion cartoner’s bucket chain by means of a vacuum

assisted overhead conveyor and QuickTransfer, which works according to the positive

transfer principle. Separate servo drives ensure safe operation at the

individual stations. In short, the Unity 500 blister packaging line from

Romaco Noack offers excellent opportunities for improving overall equipment

effectiveness (OEE).

.jpg)