- Home

- ZAHORANSKY Automation & Molds GmbH

- PRIMA Z syringe

CPHI Online is the largest global marketplace in the pharma ingredients industry

-

Products0

-

Companies0

-

Articles0

-

Events0

-

Webinars0

PRIMA Z syringe

Product Description

Production lines for any requirement

Based on customer-specific product designs, a cycle time of 15 to 17 seconds can be achieved on the three currently available PRIMA Z production lines using the no-human-touch process. Ready-to-use syringes (Pre-Filled Syringes, PFS) according to ISO11040-6 with filling quantities of 0.5 to 5 ml, cannula sizes of 19 G to 32 G and cannula lengths of 12 to 45 mm can be manufactured for immediate filling. Our PRIMA Z lines produce up to 3,400 parts per hour.

ZAHORANSKY Automation & Molds GmbH

-

DE

-

2021On CPHI since

-

500 - 999Employees

Company types

Manufacturer/Innovator

Departments

Sales

Categories

- Contract Packaging Services Automation / assembly system services

- Drug Delivery Devices & Systems (Products) Parenteral Containers

- Packaging Materials and Equipment (Products) Injectable systems and components

- Packaging Materials and Equipment (Products) Primary Packaging (Packaging Materials and Equipment (Products))

- Pharmaceutical Machinery & Technology (Products)

Specifications

- DetailsCOC/COP-based containers in the production of staked-needle syringes

- Selling PointsPRIMA Z syringe - the advantages of COC/COP-based containers in the production of staked-needle syringes

Pharmaceutical primary products with sterile needles - such as disposable needles, staked needle syringes (pre-filled syringes) and insulin pen adapters - are used in a variety of applications every day. In all cases, products made of plastic are clearly superior to their glass counterparts in terms of practical handling and unproblematic storage. We present the advantages of COC/COP based containers.

Advantages of Vials & Pre-filled Syringes of COC/COP- pH neutral surface

- Lower heavy metal content than glass

- Freezer compatibility increases shelf life, especially for highly sensitive medication

- No risk of breakage and, compared to glass, easier and safer handling for self-medication

- More freedom in product design and in cannula-position and shape

ZAHORANSKY Automation & Molds GmbH

-

DE

-

2021On CPHI since

-

500 - 999Employees

Company types

Manufacturer/Innovator

Departments

Sales

More Products from ZAHORANSKY Automation & Molds GmbH (1)

-

Product PRIMA Z vial

PRIMA Z vial - Cost savings through continuous aseptic production of plastic vaccine containers

A medication container for a liquid vaccine can use plastic instead of glass thanks to ZAHORANSKY's advanced injection mold tooling and manufacturing equipment. This is accompanied - due to the eliminatio...

Frequently Viewed Together

-

Product DataCollector - High performance IT Infrastructure for Manufacturing

The plus10 DataCollector provides a high-performance data infrastructure for the acquisition and pre-processing of machine data from any source such as sensors, machine or robot controllers. Its simple configuration and implementation transforms machine data into Big Data and creates value through high-fre...

-

Product Autoinjectors & pens

Proven track record in managing parenteral customized solution and large scale industrialization projects of Autoinjectors and Pens with top pharmaceutical companies.

Our offer:

- disposable & reusable pen injectors

- Taylor-made autoinjectors & pens

-

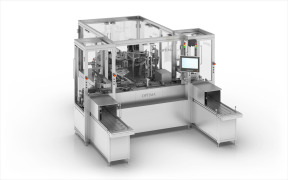

Product Pre-Filled Syringe (PFS) Robotic Machine

Introducing Harikrushna Machines Pvt. Ltd.'s Prefilled Syringe Machine, meticulously crafted to GMP standards, ensuring top-notch quality for pharmaceutical industry needs. Our system boasts a Robotic Tyvek Removal System for automated barrel opening and peeling, alongside a Syringe Filling and Closing Mac...

-

Product Syringe Assembling - COMBI-3SD

The COMBI-3SD is an automatic, continuous motion machine for syringe plungering, labelling and insertion into a Safety Device.

The model COMBI-4SD can perform also the external labelling of the safety device.

For further information and technical details: https://www....

-

Product FlowKiloLab

Modular plants accelerate time-to-market by using the same infrastructure for development and manufacturing. Production capacities adjust quickly, enabling faster product launches without long construction times. The use of scalable equipment enables a fast scaleup.

Module Type Package Proto...

-

Product RoSS.SHIP: Cold Chain Shipping

RoSS.SHIP secures the cold chain storage and shipping of bulk drug substance for almost one week. With its Smart Tracking & Tracing Add-on you never loose control of your product.

Highly robust, stackable, coolable and compact – RoSS.SHIP cold chain shipping container is like Fort ...

-

Product ConsiGma Continuous Manufacturing

With continuous line running at customer’s site for almost two decades, GEA Pharma & Healthcare has, from the very beginning, led the field with flexible development options that improve commercial-scale production and enable greater process understanding to be achieved with smaller quantities of mater...

-

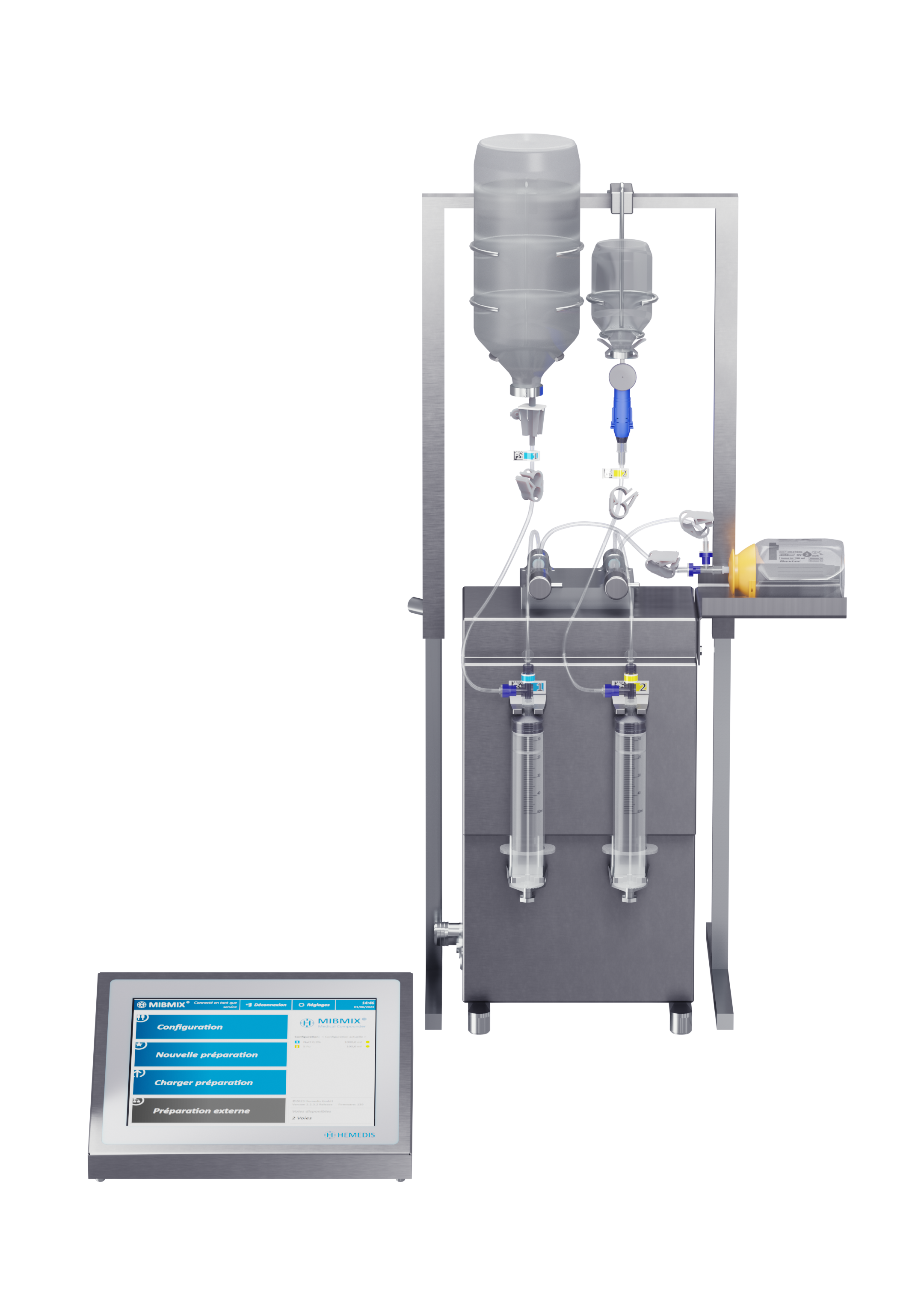

Product MIBMIX® C24 2-channel compounder for filling elastomeric infusion pumps ...

The MIBMIX® C24 2-channel compounder is a high-precision system for dosing and filling medical liquids under cleanroom conditions.

It can be used for patient specific production via an order entry software interface or batch preparation as a stand-alone device.

It is used where...

-

Product Flp fluid-bed granulator/pelletor

FLP Granulator/Coater/Pelleter is multi-function equipment integrated spray drying-granulating-centrifugal spray coating-fluid coating-drying in one body. The machine combined various process operations. Particularly it is suitable for granulating, pelleting and coating of various varieties in pharmaceutic...

-

Product Autoinjector Test System

The SA-41 and SA-61 automated autoinjector test system from Automationspartner ensures a precise product quality control and is easy to operate. The SA fulfills requirements by relevant authorities which state that combination products (autoinjectors) must be tested by the legal manufacturer prior to batch...

-

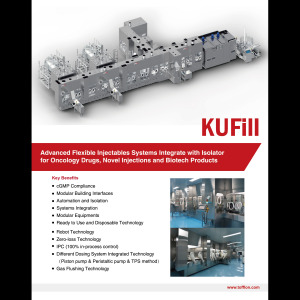

Product KUFill System

Shanghai tofflon science & technology co. Ltd offers a wide range of filling lines which includes ampoule filling line. Features: it is integrated with washing machine, sterilizing tunnel, filling and sealing machine, it reduces any potential contamination risk from human operation. Contcat us for more...

-

Product MTG Clearway Platinum®

The MTG Clearway Platinum® hose is wire-reinforced and made with high-purity platinum-cured silicone. The hose meets the USP VI, FDA, 3-A and BfR requirements. Designed for low to medium pressure and vacuum applications. Produced in an ISO 14644-1 class 8 cleanroom manufacturing facility in productio...

-

Product Formulation Development

Recipharm offer formulation development services for all dosage forms. We develop everything from simple formulations for early studies to more complex formulations suited for commercialisation.

-

Product Filling & Closing Machines for Liquid Products in Syringes in Bulk

Groninger & Co. Gmbh offers a wide range of products which includes syringes in bulk. Gmp- compliant aseptic processing of syringes and components that can rely on: innovative, high-end, precise and absolutely safe. It consist of process of cleaning, sterilizing, filling and closing, syringe assembly, ...

-

Product Omag Packaging Machine mod.C3

Continuous motion packaging machine to pack products into 4 side sealed sachets. This application is for liquid, cremy, semisolid and gelly pharmaceutical products.

-

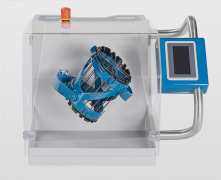

Product Isolator Technology

Safety and Performance from one source - with more than 25 years of experience. Isolator systems are becoming increasingly important to the pharmaceutical industry. Complex filling lines require competent management of the interaction between filling machine, isolator system and subsequent machines. C...

-

Product EPDM Isolator Gloves

The glovebox glove TRON 5000 is an excellent glove with its exceptional resistance against oxygen, ozone based aging, UV rays, steam, heat and chemical products.

It is recommended when working with oxidizing products, concentrated nitric acid, concentrated alkalis and alcohols.

-

Product QGF Series IV Solution Plastic-bottle Wash-Fill-Seal Machine other api e...

QGF Series IV Solution Plastic-bottle Wash-Fill-Seal Machine, is a world advanced standard pharmaceutical equipment, designed on the market demand and combined the advantages of identical machine of domestic and abroad.

-

Product Hanningfield Mills & Sifters

Gansons, in partnership with Hanningfield - UK provides high integrity machines for achieving various particle sizing processes; handling everything from bulk agglomerates to micronized material.

-

Product PLANETA

MG2 PLANETA capsule filling machine distinguishes itself by its high technology, quality and reliability.The modular design of PLANETA means flexibility and ease of use, characteristics which make this capsule filling machine ideal for R&D laboratories as we...

-

Product Safer® Retractable Safety Syringe

Very easy to use, SafeR® Retractable Safety Syringe works in just the same way as a classic syringe, but with one-click coaxial needle retraction – it automatically retracts the needle when the injection is completed.

SafeR® Retractable Safety Syringe can be manufact...

-

Product BD Accuspray™ Nasal Drug Delivery System - Enabling intranasal vaccine a...

Enabling intranasal vaccine administration - Our prefillable vaccine syringes provide multiple routes of administration options while helping enhance vaccination outcomes. BD Accuspray™ Nasal Drug Delivery System is a single dose or bidose nasal drug delivery system based on proven BD Hypak™...

-

Product Total opening drums

Total opening drums with screw lids offer maximum freedom/flexibility during filling and emptying. They provide easy and safe removal of filled liners or other valuable contents.

Plastic High Performance Packaging by CurTec is clean, safe, and secure and offers maximum protection to active ingredi...

-

Product Container design

Whether a bottle or an ampoule is to be filled, how it is filled, and what additional functions the container needs are usually based on the intended use. Rommelag’s bottelpack machines can manufacture bottles, tubes, ampoules, drop bottles, bellows containers, unit-dose or multidose containers in a var...

-

Product COP injection bottles with crimp neck finish

Unbreakable glass replacement for parenterals • High transparency • Good chemical resistance • Delivered ready-to-fill (sterilized available) • Autoclavable

-

Product Injectable Filling Machine

BAUSCH + STRÖBEL product range specializes in machines for pharmaceutical primary packaging, including equipment for washing, sterilizing / depyrogenating, filling, closing and labelling of containers such as ampoules, cartridges, disposable syringes, vials and bottles of all kinds. Our systems are des...

-

Product Device Assembly and Packaging

The injectable drug market is rapidly evolving and includes an array of delivery devices from autoinjectors to pens and other intuitive formats. We provide partnership for drug owners driven by the top-quality, complex considerations and flexibility expected. These services include assembly process des...

-

Product Thermo Compression distillation system/ Vapour Compression distillation ...

Thermo Compression distillation system is the most economical method of producing highest quality WFI. The system is available in wide range of production capacities, from 100 LPH to 5000 LPH. The system is fully automated, in compliance with GAMP5 standards and is also available to comply with 21...

-

Product Smart_Projector Pharma

The Next Generation Video Measuring Machine for Primary Pharmaceutical Packaging: Smart_Projector Pharma allows automatic, objective, repeatable, easy and fast dimensional quality check of any cylindrical parts.

Easy and FastSmart_Projector Pharma by SmartVision is the first and unique instrumen...

-

Product Atri Plus Inj. (Sodium Hyaluronate)

• Generic name: Sodium Hyaluronate 20mg/2.0mL • Indication: Arthritis, Scapular periarthritis (3 cycle injection) • CE Mark Approved -

Product TURBULA®

With the TURBULA series you can produce compounds with the highest quality requirements and excellent reproducibility.

The high mixing efficiency of these 3D shaker mixers results in the shortest mixing times and thus an extremely gentle mixing process. The mixers are easy to operate an...

-

Product Dosing Syringes and Adapters

Dosing syringes and adapters are available for glass and PET syrup bottles for various opening diameters. Dosing syringes are currently a welcome packaging solution, as dosing is extremely easy and clean with this type of syringe (no residue on the barrel of the syringe). The syringe adapter from Heinlein ...

-

Product SAN-DV Pro

For use in combination with drugs in vials, the SAN-DV Pro was designed as a fully disposable automatic needle with an integrated vial adaptor for easy drug reconstitution or mixing.

The SAN-DV Pro reduces patient anxiety and is easy to use. Additional...

-

Product SG EZ-fill ISS - Integrated Safety System

The continuing desire to reduce needlestick injuries led us to develop the SG EZ-fill Integrated Safety System. This groundbreaking, fully passive needle shield comes ready to fill and requires no additional assembly steps. SG ISS is both easy to use and intuitive to handle. Activating the automatic shield...

-

Product AF60

Ideal for pharma products, this overwrapping machine is equipped with a high-speed stacking unit capable of stacking up to 225 layers/min.. The AF60 can also be set up with a carton tilting unit (AF60AM) capable of standing on edge as many as 400 cartons/min.

Production speeds reaching 60 cyc...

-

Product Ypsomed Digital Health

Ypsomed provides pharmaceutical companies with fully integrated digital solutions. Our platform combines connected injection devices with comprehensive digital patient tools. Our aim is to facilitate research and development, shorten market access timelines and improve commercial success of subcutaneo...

-

Product BLOW FILL SEAL

Custom designed containers for pharmaceuticals, nutraceuticals, biologics, etc. all made be one single Machine - ALPS Hybrid Model 700 Series Size Range: 0.mL -2000mL

-

Product OPTIMA GSM Assembly of glass syringes

• Gentle product handling • Processes from tray handling to bonding the cannulas and hardening • Production reliability by IPC • Compact machine footprint Please get in touch for more information

-

Product Glass Ampoules

Nipro offers a wide range of high-quality glass ampoules.

Benefits • Precisely formed for reliable fill-finish operations • Stable break force facilitates easy opening • Premium glass quality • Anti-counterfeit technology

-

Product SYX-E

La SYX-E Cartridge By-Pass permet le remplissage et la fermeture double chambre de carpules ...

-

Product Compounding Aseptic Containment Isolator for Dispensing

KEY FEATURES AND BENEFITS:

Optimized Material Handling:

- Airlock Introduction: Efficiently introduce materials into the airlock, minimizing contamination risks and ensuring a smooth workflow.

- ...

-

Product Pharmastill Multieffect

The Pharmastill multiple effect produce distilled water for injectable use, which meets the requirements of the International Pharmacopeias including USP, EP and JP.

-

Product Thermoform Packaging Machine: RX 4.0

Innovation at its best !

The RX 4.0 offers maximum process reliability. Using closed control circuits, the sensor system constantly captures all the relevant process parameters, such as those for forming, evacuation and sealing. All the process stages are coordinated to the optimum level...

-

Product BECOMIX-pre-phase tank (M/MV)

Mixing, melting and storage vessel – optionally available with homogeniser, integrated CIP-system or in unpressurized execution.

Fastest possible tempering and melting of e. g. pellets or block waxes.

For fat and water phases, liquids, solutions, suspensions, eye d...

-

Product Alimenta TPN bags: new line made with a special material which improves ...

Nutriline is the standard EVA TPN bags line, while Alimenta is the new line made with a special material which improves the TPN bag features:- Transparency: Alimenta is manufactured with a transparent film which allows an easy inspection of the solution contained in the bag. - PH stability: contrary to ... -

Product Device components made by Pulp-Injection

Customized components for self-injection devices

Pulp-Injection molded products have similar features and functions as plastic parts, e.g. high rigidness and

detailed design options.

Components made by Pulp-Injection are combinable with

other materials to ensure...

-

Product QD Series Bin Washing Station

QD Series Bin Washing Station is mainly used in solid preparation process for vessel automatic washing and drying. It can satisfy different specification pharma bins or IBC washing requirements. Considered as ideal equipment for vessel automatic washing, it is widely used in pharmaceutical, chemical and fo...

-

Product BONDEX PFS Inj. (Ibandronate)

Treatment of Pstmenopausal Osteoporosis.It contains Ibandornate sodium monohydrate 3.375 mg/3mL in PFS(Pre-filled syringe).Aministration: 3 mg every 3 months.

-

Product Autonomy solutions for assembly machines

DESOTEC offers systems and solutions to increase the autonomy at assembly machines

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.jpg)

-comp245604.png)