- Home

- Kevision Sysytems

- KevSecure - Track & Trace and Serialization Systems with Tamper Evident Technology

CPHI Online is the largest global marketplace in the pharma ingredients industry

-

Products0

-

Companies0

-

Articles0

-

Events0

-

Webinars0

KevSecure - Track & Trace and Serialization Systems with Tamper Evident Technology

Product Description

Kevision offers

complete integrated Solution for Serialization& Track and Trace which

includes Software at Global Level, Plant Level and Line level along with the

Integrated Hardware as per line configuration for Carton as well as Bottle

packing lines.

A) Kev Secure - Server Software – For Global / Plant Level

B) Serialisation System

a) Online Print and Inspection system

b) Online Print and Inspection system with Tamper Evident Labeller

c) Offline Print and Inspection System for Flat Cartons

d) Online Printing on Labels for Bottles

C) Aggregation System (Parent Child Relationship)

a) Manual Aggregation - Scanner based Aggregation

b) Semi Auto / Fully Auto Aggregation - Camera Based Aggregation

D) Pallet Aggregation System

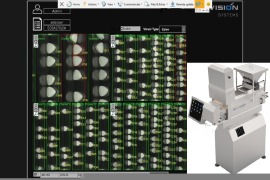

Online Print and Inspect System : Kevision offers robust

and completely Integrated Top and bottom belt based Servo Driven Print and

Inspect systems, to meet requirement of high print Quality (Grade A/B prints)

along with encoder based logic for true and actual rejection of the products.

Kevision used high resolution camera with proper illumination for decoding and

Verification of the printed matter.

Function:

• Combination of select able GS1 applications is printed onto each product.

These include the combination of a unique serial number, an expiration date, a

batch number or a global trade item number.

• The data is encoded into a machine-readable 2D data matrix code.

• The 2D matrix code and human readable text are printed on the package.

• The camera reads both the 2D data matrix code and human readable text before

the software compares the content and checks the printing for accuracy and

quality.

• All information can be stored in a centralized database, which enables the

tracing of individual products throughout the supply chain

Key Features

• Completely Integrated System with Printer and Vision Inspection

System along with Rejection and its

verification Logic

• Speed Upto 400 cartons or parts per minute

• User friendly GUI and simple to operate.

• Auto Teaching of Inspection Parameters.

• Controlled False Rejection – less than 0.5 %

Kevision Sysytems

-

IN

-

2017On CPHI since

-

-

-

A-1-3706 Phase-4,Vatva Industrial Estate, GIDC Vatva, Ahmedabad 382445, Ahmedabad, India

Categories

Specifications

- Selling PointsConvenience; Experienced Technicians; International Approvals/Standards; Packaging; Product Features; Product Performance; Quality Service

- Supplied fromIndia

Sales Markets

- Middle East Region (e.g. UAE)

- Oceania

- North America (USA, Canada)

- Africa

- Central America (e.g. Mexico)

- East Asia (e.g. China, Japan, Korea)

- Europe - EU countries

- Europe - non EU (e.g. UK, Russia, ex-CIS countries)

- South America (e.g. Brazil, Colombia)

- South Asia (e.g. India, Pakistan, Sri Lanka)

- South East Asia (e.g. Thailand, Philippines, Singapore)

Kevision Sysytems

-

IN

-

2017On CPHI since

-

-

-

A-1-3706 Phase-4,Vatva Industrial Estate, GIDC Vatva, Ahmedabad 382445, Ahmedabad, India

More Products from Kevision Sysytems (2)

-

Product TabSecure- Tablet Inspection System

TAB Secure is a UHR Colour Camera based online Inspection systems being Installaed over the Vibratory plates on the Tablet Countering machine in the Bulk Packing Line.

System has a high inspection rate of up to 1 Million Tablets per Hour, considering 24 Channels on the Bulking Packing Line Cou... -

Product Bli Secure - Blister Inspection System

Bli Secure – Blister Inspection System

BliSecure (Blister Inspection System) is a Colour Camera based online Inspection and verification of Blister based Pharmacuetical products on various forming materials used on Blistering Machines. BliSecure ensures in process quality assurance a...

Kevision Sysytems resources (1)

Recommended Products

-

Product The Luer Vial by GEMÜ

The Luer Vial by GEMÜ combines optimal shelf life with standardised containers that can be filled aseptically. Safety and user-friendliness are enhanced by a customised applicator that allows precise drug delivery by single-handed operation.

The Luer Vial by GEMÜ was developed as a modular pa...

-

Product Zherox® b-pack

Zherox® b-pack is the new portable biodecontamination system by AM Instruments.

The innovative HPE technology of Zherox® applied to a lightweight system, allowing maximum operational simplicity, complete safety for the operator, and proven effectiveness.

Easy bottle storage, qui...

-

Product Drug Delivery for Enhanced Bioavailability of BCS2 (Poorly Soluble) Comp...

Engineered to bring together advanced silica technologies with challenging active pharmaceutical ingredients (APIs) to effectively formulate a large class of poorly soluble but otherwise promising compounds, Grace’s SILSOL® silica-based drug delivery technology provides solutions for poorly soluble active ...

-

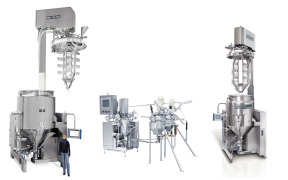

Product Process Plant Master Plant

The IKA Master Plant homogenizing and emulsifying plant is a universal mixing plant developed for the production of emulsions and suspensions in the pharmaceuticals industry in particular, but also in the food, beverages, cosmetics and chemical industries. The plant is GMP-compliant and guarantees ...

-

Product MTG Puralife™

The MTG Puralife™ hose was developed to convey pure fluids. The special hose design combines the benefits of a black Perfluoroalkoxy inner liner (that is, an excellent impermeability and chemical resistance) and the benefits of the platinum-cured silicone structure, translucent and pharma-grade. Thanks to ...

-

Product Proton drops

Rickets prophylaxis.

DOSAGE8 drops (400 I.U.) per day for a 18-months period.1 drop contains: 50 I.U. of Vitamin D3.

INGREDIENTS

Vitamin D3 (Cholecalciferol).

CHARACTERISTICSMicellar solution in physiological solution easy to be mixed with all liquids or foods. Tasteless...

-

Product Toxic Sterile Dispensing Isolator

FPS recently designed and manufactured an isolator to dispense up to 100kg of potent sterile API in specific containers to be connected to the process equipment.

During the discovery phase of the customer needs, the various stages of the process were analyzed:

1) introduction of th...

-

Product PENTAFILL®

TekniPlex Healthcare can provide its customers with machines for the filling of single-dose containers. The series of Pentafill machines guarantees total flexibility to meet a wide range of needs, for production on an industrial scale or small production batches, for laboratory tests or research and develo...

-

Product Betahistine diHCl

Grünenthal GmbH offers a selected range of products which includes Betahistine diHCl, as API, bulk tablets and/ or finished dosage form. Please contact us for more information.

-

Product Turntable Machine KDT

The Turntable Machine KDT packages small to medium quantities using the latest machine technology and impresses with its low acquisition cost, reasonably priced format components and low energy consumption.

State-of-the-art machine technology for the packaging of small to mediumsized batches whi...

-

Product Folding cartons for pharmaceutical industry

Working for pharmaceutical industry we have developed a comprehensive offer that is tailored to the requirements of our Customers. We offer various products and solutions. We advise on the selection of paper, cardboard, production and refining processes.

-

Product GENiSYS Lab

AST’s GENiSYS Lab bench top systems are ideal for drug product development, process development, and small batch cGMP production applications. Each system is designed to automate the critical aseptic operations for vial, syringe and cartridge processing to reduce contamination risk and product variability....

-

Product SoftGroup® SaTT Uzbek Hub Gateway

SoftGroup® SaTT Uzbek Hub Gateway provides a connection and data exchange between Uzbek National Track & Trace System – Asl belgisi and all supply-chain participants (MAHs, Manufacturers, Importers, Wholesale trade enterprises etc.). The solution allows requesting and receiving the crypt...

-

Product Filling & Closing machine

High speed filling and closing machines for large volume parenteral solutions.100% weight control / Filling from 0.1 ÷ 1.050 ml. / Output up to 24,000 uph. / Conforms with cGMP - US FDA.

-

Product Development

Synerlab provides wide range of services which includes development. Contact us for more information.

-

Product GPX Porosity

Material porosity is a relevant parameter in many production process with dry compounds. Actual porosity measurement technologies are using destructive methods. Several disadvantages are connected with the determination of the porosity. The pharmaceutical production of tablets uses the porosity measurement...

-

Product TS-AS - cGMP Terminal Sterilizer

The Sterilizers type TS-AS are specifically designed for the Terminal Sterilization of liquids contained in sealed containers (plastic bags, glass bottles, BFS bottles, syringes, ampoules, etc...) as they are prepared to provide automatic differential pressure compensation based on product probes (RTD...

-

Product OctoPlus FF® Simplifies The Setup of Your Filling Line

Secure Your Final Filling

OctoPlus FF® provides a completely single-use alternative to traditional stainless steel “break tank “or “buffer tank” systems in a wide range of applications. OctoPlus FF® can be configured with a large variety of components and connectors.

-

Product ALLERGOFF® allergen-neutralizing spray

ALLERGOFF® spray is an innovative solution for neutralization of house dust allergens. It is designed to protect against harmful impact of allergens present in house dust, such as: house dust mites allergens, pollen, pet and fungal allergens. It neutralises house dust allergens by changing their chemical ...

-

Product RoSS.pFTU: Controlled Freezing & Thawing Platform

The plate-based freeze-thaw platforms from Single Use Support enable controlled freezing and thawing of drug substances. Transferable recipes enable full scalability and compatibility from the lab to blockbuster production. Thanks to RoSS technology all batch sizes and single-use bags from all establi...

-

Product MIXER / DISSOLVER

Our line of stainless steel mixer/dissolvers is suitable for all pharmaceutical application fields, the systems are fully customizable according to user needs.

There are many combinations, mixing, dissolution and thermoregulation of the product, liquid analysis, weighing and dosing us...

-

Product SOLUBLE TECHNOLOGY

Soluble formulations are solid immediate release forms that need to be dissolved in water with rapid stirring at the time of administration. They yield an oral solution or suspension, depending on API solubility. In both cases the API is ready for absorption in the gastrointestinal system resulting in a fa...

-

Product Containment Solutions

Fabtech Technologies provides wide range of pharmaceutical products and solutions which includes containment solutions. The aerodynamic means for efficient function barrier system. The innovative strategy for containment uses various types of physical, aerodynamic barriers that create an improved level of ...

-

Product Essentia

Essentia opens a new generation of capsule filling machines, perfection made easy. Inspired by a human-centered approach (HCD), the machine has been designed for users who search for perfect capsule filling, ergonomics and attractive price, all combined in one capsule filling machine. Essentia offers the b...

-

Product WDCI (Weighing & Dispensing Containment Isolator)

Weighing and Dispensing Containment Isolators (WDCI) are advanced containment systems providing controlled negative pressure environments to maximize personnel protection during weighing and dispensing of potent compounds. Esco WDCIs provide standard configurable designs able to adapt to various weighing a...

-

Product Tech4Pharma - Excellence in Manufacturing

Published four times a year, “Tech4Pharma“ features a broad spectrum of exclusive technical articles and original scientific submissions in German, written by authors with solid expertise in pharmaceutical production, machine engineering and related technical fields. To ensure the high quality of the conte...

-

Product Visual Rotating Inspection Machines

Inspection machines engineered to operate at high speeds on automatic production and packaging lines, designed to inspect a wide range of glass or plastic containers for liquids (such as solutions, suspensions, emulsions and oil-based products), powders or lyophilized products.

Our technologi...

-

Product CLF-IS - Compact laminar flow isolator system

The Compact Laminar Flow Isolator System is a modular cGMP Class A/ISO 5 isolator system specifically designed for safe handling of hazardous compounds (Chemotherapy, Oncological Applications) in hospital pharmacies.

-

Product BLEFASTOP (Ophthalmology - Blepharitis)

The product has been specifically formulated as an adjuvant in blepharitis treatment. This product contains a derivative of Tea Tree Oil (Terpinen-4-ol) characterized by an anti-inflammatory, antimicrobial and acaricidal activity against Staphylococcus aureus and Demodex (either directly or by carrying...-comp246544.jpg)

-

Product Lecithins

VAV Lipids specializes in the production of cGMP Phospholipids & Lecithins from Natural sources (Soybean, Sunflower, Egg) and Synthetic Lipids. VAV also produces other Specialty Lipids like Glycerophosphocholine (GPC), Cholesterol as well as Phospholipid based Delivery Systems. Our products find appli...-comp285903.png)

-

Product Drum Laser - Tablet & Capsule Marking & Drilling Machine

Powerful multi-lane Class 1 Laser drilling and marking / writing / etching machine that provides single or double-sided laser drilling or laser writing for mid-sized pharmaceutical, nutraceutical or confectionery productions. With output rates of up to 180,000/hour, the Drum Laser works with tablets, capsu...

-

Product Microfluidizer technology

By using microfluidization technology process, Skyepharma provides solution to increase bioavailabity of poorly soluble APIs (micro and nanoparticule). It is also an interesting technology for micro and nano emulsion manufacturing.

-

Product Baby Joy Gas Relief Baby Gas Corrector Drop

Konicare Baby Joy Gas Relief Oral Solution which is especially used in newborn babies, specially formulated for relaxing the colic and gas aches. This drop which is given to babies directly from the mouth is quite practical because of its squeezable bottle design.

-

Product SELF ADHESIVE HANGING DEVICE

The Self Adhesive Hanging Device for infusion bottles is one of the latests Pilot Italia patents.

Our R&D team has developed and patented three labels with an innovative handle and various functionalities, aimed at simplifying and supporting operating room staff while meeting custome...

-

Product Tyvek Filling Needle Autoclave Bags

Keystone Cleanroom Products 1422A Tyvek® Autoclave Filling Needle Bags with drawstring closures are made from 1422A DuPont™ Tyvek®. These are an efficient and consistent method of preparing difficult to wrap pharmaceutical filling needles/nozzles, for steam sterilization. After sterilization, the covered c...

-

Product Industrial CO2 Extraction plant

The supercritical CO2 extraction and other processes based on CO2 as a solvent are of high interest for different areas of the pharmaceutical industry. This is mainly due to the unique properties of CO2 which allow the extraction of sensitive substances selectively and gently.

Industrial applications an...

-

Product GLOVE BOX SGS

Many laboratory and production applications currently require the availability of a confined space for the enivoronnment and product protection. This Glove Boxes line is a “Fully Modular Line” that allows to configure the system to the different needs of research; the Glove Boxes, made of PMMA (polym...

-

Product Security

Defending products and customers/patients from counterfeiting is a priority. Each product has unique characteristics and for this reason we have studied multiple solutions that can be combined with each other to achieve the desired degree of security.

• Security materials and die cuts. • Sec...

-

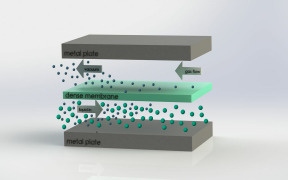

Product Pervaporation Technology

Pervaporation is a liquid/liquid separation process using a selective and dense membrane.

By creating a vacuum or introducing a flow of purge gas on one side of a dense membrane, volatile compounds in the liquid present on the other side will selectively diffuse through the membrane....

-

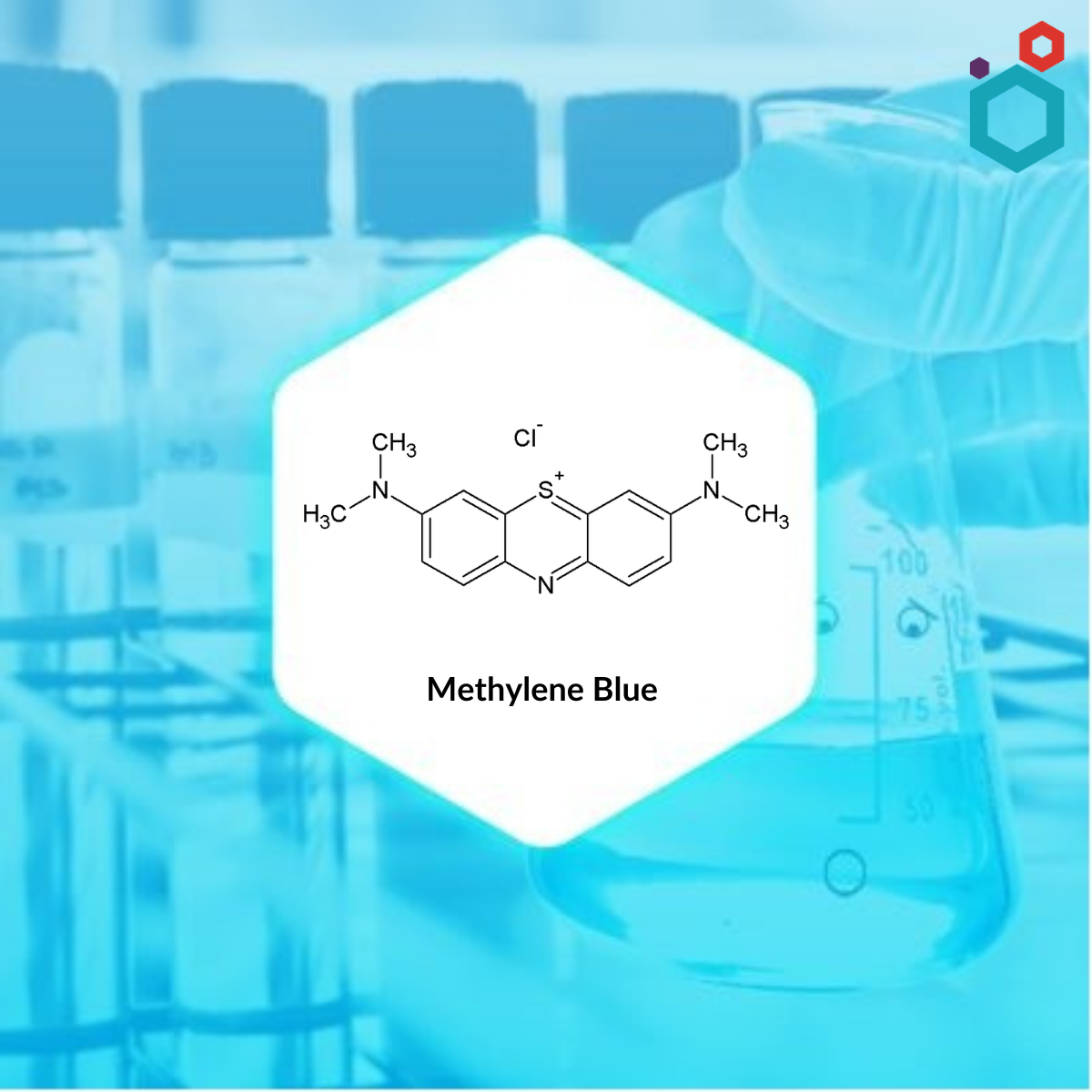

Product Methylene Blue USP

We are manufacturer of Methylene Blue USP 40. We are ISO 9001:2015 certified & cGMP complying manufacturer. We have DMF for this product. Very soon we going to apply for WHO as well as Written Confirmation.%20(1)%20(1)-comp246058.png)

-

Product HSA 120

The HSA 120 equipment belongs to a family of non-destructive analyzers intended for monitoring headspace gas compositions in optically transparent and sealed containers. It employs a non-invasive laser-based technique for monitoring the headspace levels of gases such as oxygen, carbon dioxide and moist...

-

Product HELIX CORE

HELIX Core is a machine for vertical lifting, dedusting and polishing of tablets, capsules and softgels of various shapes and sizes. The products are conveyed in gentle manner to different heights at adjustable speed, controlled via user friendly graphical interface. Compact, mobile and modular design m...

-

Product Filling & Closing Machines for Liquid Products in Eye Drop & Nasal Spray...

groninger & co. gmbh offers a wide range of filling and closing machines for pharmaceutical products in small plastic bottles. High-capacity, accuracy, safety and user-friendliness are the characteristics of our highly flexible processing equipment for filling and closing small plastic bottle...

-

Product ESMOBLOC 10 MG/ML SOLUTION FOR I.V. INFUSION

Active Ingredient: ESMOLOL HYDROCHLORIDE

Therapeutic Area: BETA BLOCKER

-

Product Aromatherapy: decongestant nasal spray

Laboratoires Gilbert is specialized in Aromatherapy.Breathing decongestant nasal spray is a 2 in 1 product : winter diseases + Allergy season.Recognized anti-inflammatory action in allergic rhinitis

Reduces swelling of the mucous membrane

Decreases inflammation

Instant cooling effect

...

-

Product Combi Lines

Dual Combi Lines (Vial+PFS) / (Vial+Ampoule)Triple Combi Lines (Vial+PFS+Cartridge) / (Vial+Ampoule+PFS)Robotic / Semi Automatic OperationsCapacity ranges from 25 to 400 containers/minute.

-

Product PuroMill™ Pharmaceutical Grade Milling Media

PuroMill™ is the only commercially available cGMP pharmaceutical-grade milling media for reducing API particles to the nano scale. Made of advanced copolymer beads, PuroMill enables the creation of pure drug nanoparticles < 100 nm for the development of oral, injectable, pulmonary, ophthalmic and o...

-

Product Omag Packaging Machine mod. CP

Intermmitent motion packaging machine with sealing plates technology to guarantee perfect sealing and high quality of the sachets, without any wrinkles in order to maintain the integrity of the product. Possibility to pack different products in classic 4 side sealed sachets or shaped sachets. The idea...

-

Product Hot Stamp Transfer Foil for IV-bags

For optimum performance in hot-stamping foil technology we recommend this high-grade product. It is widely used in the pharmaceutical industry and produces superior prints.

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.jpg)