How tech transfer and process optimisation can help patients – CPHI North America Interview

.png)

Following a successful few days in Philadelphia for CPHI North America, I was able to discuss some of the sessions with our expert speakers, gaining a little more insight into the key topics from the event.

In this interview Subramanya Nayak, Programme Manager at AbbVie, discusses his presentation 'Tech Transfer and Process Performance Qualification (PPQ: Ensuring Quality, Robustness and Consistency in Pharmaceutical Manufacturing)' and how discrepancies between companies and regions can affect this.

Could you please introduce yourself and your role?.png)

My name is Subramanya Nayak, and I work at AbbVie. My primary responsibility is CMC programme management and lead our external manufacturing activities. My group supports all the clinical programmes for small molecules, ADCs, and novel modalities. We are constantly collaborating with external vendors and CDMOs, and we are also actively seeking new technologies for new modalities.

Would you be able to give us a brief overview of your talk at CPHI North America?

Yes. Today, I am going to discuss one of the key issues we currently face when launching new products, which is tech transfer and process performance qualification at a new CDMO. How do we approach this? What is the best strategy? In my talk I will be sharing strategies we have been using for many years that have led to successful product launches. Additionally, I will touch upon some industrial best practices. Working with CDMOs presents challenges due to multiple customers, resulting in a lack of standardised approaches. One of the challenges we constantly encounter is that each CDMO has their own metrics and procedures. We are exploring the possibility of standardising and harmonising these metrics across the industry to enhance agility for bringing life-saving medicines for our patients.

Are there any more universal challenges that you’ve come across?

Yes, one of the biggest challenges lies in the regulatory aspect. The pharmaceutical industry is highly regulated, and regulations vary across different countries. This poses a challenge. Additionally, quality systems differ among companies, especially for CDMOs that work with multiple customers and have to meet different quality requirements. This presents another challenge, it becomes difficult to provide a standardised procedure, SOP, that satisfies all customers.

Do you think that there could be a way to have more universal quality assurance standards?

Yes, forums like CPHI, which we all attend, inspire conversations like the one I had today. These events bring together the best and most innovative pharmaceutical companies, as well as CDMO partners, to collaborate and establish a unified standard quality assurance system. Additionally, regulatory agencies such as the FDA and EMA should play a role in driving this standardisation. During audits, they should adopt a consistent approach globally rather than being country-specific.

Do you think that would also help in terms of having more standardised quality assurance? And do you think there's also a push towards efforts in that respect to make processes more sustainable and more efficient?

If we can standardise the tech transfer process, it would greatly contribute to sustainability. Everyone is focused on reducing waste and streamlining processes. These are important considerations in process development and technical transfers. Sustainability is not only about the environment but also about the economy and social issues. There are CDMOs in developing countries with unique needs and underrepresented populations. It is crucial to make our products accessible to them, which is an integral part of sustainability.

Is there anything that you think could be done with to support companies with things such as tech transfer? What are some examples of good practices?

Well, the implementation of good practices has been a result of hard lessons learned over the years. At AbbVie, we are striving to change the mindset of relying solely on past experiences and instead focus on implementing the best practices in collaboration with our external partners. To achieve this, we have developed a standard procedure.

Whenever we collaborate with a new partner or external vendor, we provide them with this SOP and educate them on the importance of robust tech transfer process. Knowledge-based approaches are crucial, as tech transfer essentially involves transferring knowledge. The facilitation of this transfer depends on the project's complexity. Some projects may be linear and have only one supplier, while others require communication with multiple supply chain partners. Harmonising these processes also is a challenge.

Additionally, we must rely on our vendors' quality systems as we cannot impose our quality system on them. However, we can identify any gaps in their system and address instances where they may be overdoing or underdoing them.

Are events such as CPHI North America, when they exhibit case studies, a good platform for knowledge sharing and information dissemination?

Yes, that was one of the motivations for attending this conference – to share this information and learn more. The topics I will be discussing today are relevant to both innovative pharma companies and our CDMO partners and CROs. It is important that we engage in open and transparent discussions in forums like this. Ultimately, we are all companies focused on improving the lives of patients. We need to find the right, uncomplicated approach that our stakeholders can support. The information I am sharing today is not new; rather, I am aiming to present it in a standardised manner. By utilising platforms like CPHI, we can disseminate this knowledge effectively.

Are you seeing a lot more trends from companies focusing on patient-centric approaches?

Yes, there is a noticeable increase in companies adopting patient-centric approaches. At AbbVie we prioritise patient-centricity in each phase of discovery and development. We are constantly exploring opportunities for product customisation and personalisation to cater to individual patient requirements. This may involve modular manufacturing approaches, flexible production lines, and agile supply chain networks. By offering tailored solutions, we can address specific patient needs and improve treatment outcomes.

What do you think are some of the biggest trends that you're going to be seeing in industry?

Nowadays, the biggest trend for us is a greater focus on novel modalities and precision medicine. With advancements in genomics, we have gained valuable insights that allow us to target specific patient needs more effectively. This enables us to support patients in a more efficient manner. While there is always pressure to meet production demands, we also strive to provide patients with more choices. The challenge lies in how quickly we can bring new products to the market that will shape the next phase of this century.

Do you think there's going to be difficulties with that in the North American market as it currently stands?

The trend has indeed shifted, and now we have external vendors or CDMOs who offer their technologies to produce medicines for our patients. Innovative pharma companies take significant risks in developing these medicines. When working with vendors, they often prioritise licensing and profit-sharing royalties. However, it is important to consider the long-term perspective, as drug development can span a 10-year period, subject to evolving laws and regulations. Therefore, it is crucial to work towards mutually beneficial scenarios that minimise supply-chain disruptions and avoid excessive time spent on contract discussions.

Related News

-

News Technology revolutionising drug substance development: CPHI North America Interview

From one of the content tracks at CPHI North America in Philadelphia, USA, in May, a lightning round talk was presented on 'Combining Biology and Chemistry for Smart Manufacturing', from Masha Kononov, Ingenza. In the following interview K... -

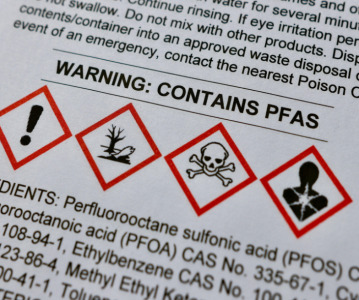

News How are new PFAS regulations impacting excipient manufacture? – CPHI North America Interview

In another interview from CPHI North America in Philadelphia in May, Peter Schmitt from Montesino Associates talks about his presentation on 'Navigating the Waters of Change: The Impact of New PFAS Regulations on the Manufacture of Excipients ... -

News Providing solutions for special populations – CPHI North America Interview

In Philadelphia in May on site at CPHI North America we were able to meet with some of our speakers regarding their presentations. In the following interview Srinivasan Shanmugam, Executive Director, Pharmaceutical Sciences, Business Sup... -

News Angels for Change: Guardians of the pharmaceutical supply chain

Angels for Change is an organisation that aims to build up resilience in the supply chain, by linking real life cases of patients that have been affected by drug shortages, and working to rectify and prevent them. -

News CPHI North America 2024 – From the Floor

Welcome to Philly! CPHI North America once again graces the Philadelphia Convention Center, 7–9 May 2024. -

News On Track at CPHI NA 2024: Supply Chain Economy with US Pharmacopeia

On the 7–9 May 2024 in Philadelphia, CPHI NA will be presenting an unmissable agenda, filled with content across 4 main tracks. In the following interview the Supply Chain Economy Track sponsor, the US Pharmcopeia introduces the track, and w... -

News Women in Pharma: Diversi‘tea’ at CPHI North America

CPHI North America will unite the pharmaceutical supply chain in Philadelphia from May 7–9, 2024 for 3 days of innovation and connections. As part of the content Agenda, our Diversity Track will bring the industry together to discuss the imperati... -

News On Track at CPHI NA 2024: Sustainable Futures with Thermo Fisher Scientific

On the 7-9 May 2024 in Philadelphia, CPHI NA will be presenting an unmissable agenda, filled with content across 4 main tracks. In the following interview the Sustainable Futures Track sponsor, Thermo Fisher Scientific gives an overview of what to expe...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)