Angels for Change: Guardians of the pharmaceutical supply chain

.png)

Angels for Change is an organisation that aims to build up resilience in the supply chain, by linking real life cases of patients that have been affected by drug shortages, and working to rectify and prevent them.

In the following interview, Laura Bray, Chief Change Maker at Angels for Change tells us about her personal story that led to the founding of Angels for Change, and how this has led to ensuring life saving treatment reaches the patients that need it.

Could you please tell us a little bit more about Angels for Change and the work that you do?

My name is Laura Bray, I'm Chief Change Maker and Founder of Angels for Change. Angels for Change has a mission to end drug shortages through advocacy, awareness, and a resilient supply chain. I founded Angels for Change in 2019 after my own child faced three life-saving, protocol-altering drug shortages during 9 months of paediatric cancer treatment.

At the time, there was not any organisation dedicated to drug shortages. Though many stakeholders had awareness or influence in drug shortages, there was no one working to end them. In fact, the conversations were all around a word called mitigation. Mitigation asks, what do you do with available supply in life and death pharmaceuticals? I think no, we need to ask ending questions, not mitigation questions, why are there shortages? What are the root causes? How are we fixing the root causes? How are we ending drug shortages?

Because if you ask, how do we end drug shortages? The answers all surround how do we make sure there's additional supply? How do we ensure that we have additional capacity to increase supply? How do we ensure that supply gets to patients during disruption? How do we ensure that the market recovers quickly?

At the time there was no patient advocacy nonprofit, at least in the USA. I haven't met anybody else that does what I do. In the country with a mission to end drug shortages, we're also the only organisation that takes contact and calls directly from patients, physicians, hospitals, pharmacists in an active drug shortage and works to find them available supply or increase supply and fix the scenario.

So how do we have a more resilient and reliable pharmaceutical supply chain? How do we ensure that we have just in case supply? How do we ensure that that supply gets to everybody without disparity? How do we ensure stewardship of that supply? How do we build a system that ensures access? Those are all the things we work towards.

That's the big picture.

When you're talking to patients in those crisis modes, that must be a very difficult part of the job.

It's terrible and heartbreaking and heart wrenching. And every single time I'm brought back to the same feelings I had as a parent and caregiver who was shocked and scared and hopeless and didn't know how I was going to figure out how to save my child and ensure that she got the medicine she needed.

So they’re hard conversations and they're terrible to take and I do them because no one was there for us to take a call. And so it really drives us to know that there's true patient impact happening.

This is supply chain management. It's a + B = C right? I would go as far as to say this is not even prediction. We know there's X amount of patients that are going to get this disease every year. We know exactly what the treatments are and in what order those treatments are, so this isn't even high order supply chain management analytics. This is math A+B with a little bit of extra equals.

At the beginning of Angels for Change, I thought, I don't really know what I can do, but I know I can validate somebody and tell them you're not alone because even if somebody had done that for me, it would have made things easier. And you know, all the members of the supply chain do want to end drug shortage.

In the supply chain, let's say the data is 96% or 98% of medicines are getting to the right place at the right time, right? That that's not that bad. But each individual medicine, in short, that doesn't get to the right place at the right time, just has catastrophic consequences for that patient for that hospital. So if you are looking at the big picture, you could forget the catastrophic single failure.

Could you please outline some of the reasons why these catastrophic drug shortages occur in the first place?

We are actually in an all-time high in the USA for drug shortages, quarter one of 2024 saw 323 shortages and that's the highest number of shortages that's ever been recorded. Drugs that are recurrently in shortage are from the generic injectable space.

There are a few main drivers of drug shortage, first is price. The lower the price, the more likely it's to be in shortage. The next one is concentration or consolidation, if all the medicine is made at one facility or in one place in the world that's been consolidated to single source or single geography, it's more likely to be in shortage.

Next, if it has a history of shortage, it's more likely to be in shortage. Another reason is if it's had a quality assurance event, a quality event. Those things aren't fixing themselves. They often end up having another event in in the future. That means that you know we are allowing ourselves to have a problem and then we address that problem reactively, but then we don't actually solve it. The final one is the more complicated it is to manufacture, the more likely it is to be in shortage.

So those are like the drivers and that really highlights the generic injectable space because the generic injectables are harder to make, they're all lifesaving, and they have been around for a long time, so they're very low in price, but they're also do the most of the saving of our lives.

What we see is that blockbuster medicines are rarely in shortage. These high-profit blockbuster drugs, the things that are doing these exciting new things, they're very rarely in shortage with the exception of when demand far outweighs the manufacturing capabitlity such as with Wegovy etc at the minute, but the backbone of our healthcare system is extremely unstable right now. And these medicines have been around for 50-70 years.

Around 56% of shortages right now are generic drugs that cost less, and that are sold for less than a dollar.

And if you move it up to the next bracket, the majority of them are less than US$10. And so what we're talking about is a systemic crisis that actually if we do the work to fix it, won't really cost that much money.

It actually wouldn't cost compared to the life-saving work that it does. So that's kind of that's that's the situation that we face.

There are outliers. There are medicines that are branded drugs that or something that just enters the market.

Often it might be on shortage right away. Like what's going on with the diabetes. But they're they will stabilise because they're branded. They have a lot of profit. There's a lot of incentive.

You see all the manufacturers buying new facilities and building new facilities for this medicine that will stabilise.

But the ones that I'm really worried about are these generic, essential medicines that do all the life-saving that just don't have the economic viability.

And we always say we know we know what the value of saving a life is. That's what's happening in the industry and you know, we've got to figure out how to change that value equation.

How effective is the industry at, first of all predicting these disruptions and then reporting on them as well?

So, so our three general principles to ending drug shortages do rely on transparency. We need to see the problem so that we're solving the right problem. We need redundant layered solutions for each of these problems.

Then we need a purposefully connected supply chain, a chain that is connected both all the way to the shelf and all the way back in a patient centric design. Not for profits, but for patient care.

When discussing the first one, transparency, there is a lot of information out there already. I say that because a lady from Tampa was able to use public information to kind of navigate this and figure it out. But there are holes and gaps.

There are lags of information and more importantly, there are not proactive or early warnings and there are also pieces of information missing and that creates a rumour mill.

It creates fear.

It creates protective practices that makes it even harder to recover from and design about prediction. We work a lot with the US Pharmcopeia and they are actually part of the supply chain track at CPHI North America, and we've been working with them since their founding on the medicine supply map. That's what Angels for Change uses. We believe it is true prediction.

It looks at the drivers we talked about, it uses data to predict and give a score of how vulnerable something is.

They're doing fantastic work and so when we're looking to do proactive solutions, we look at the USP data and the vulnerability score.

We have a Venn diagram looking at the vulnerability of score from USP, then we pull in a vulnerable population.

So we're looking at people, as some populations are more vulnerable to drug shortages than others.

And the vulnerability then we're looking at patient impact. Is there a suitable alternative or not? Is this life saving or not?

Then we're looking at like resource allocation cause we're a small grassroots funded organisation. We start with USP’s Medicine Supply map and vulnerability scores because we're trying to put in solutions while the market is healthy, before it's short, so that there is a solution that patients can rely on when there is a disruption. We have correctly predicted a handful of shortages and had supply ready to infuse into the marketplace. From starting in 2022 we have predicted 750,000 shortage treatments.

What do you think the biggest challenges to supply chain integrity over the next couple of years will be?

If you would ask me two years ago I would have said the biggest challenge was awareness. Nobody wanted to talk about drug shortages. Nobody wanted to talk about supply chain integrity. No one wanted to even admit it was an issue, and even when they did, they said it's not a priority. That challenge is gone. People know what a shortage is. They know what a supply chain is. Then this awareness is a dramatic shift for the better right?

Awareness making sure people know this is a crisis and it deserves fixing and building a resilient supply chain. So we actually have made unbelievable strides in the advocacy and awareness space. The challenge now is, will we have the resolve to do the work that it is actually going to take? It will be work - if it was easy, it would have already been done.

If this was easy, my family wouldn't be here. My child would have gotten her care. We would have moved on with our lives. Will we have the resolve to come together and it will need to be patient, advocacy, and nonprofits. It will need to be industry, from the private sector and it will need to be public policy.

And so we must come together. That's the biggest challenge.

What can the industry do to mitigate drug shortages and increase supply chain resilience?

So a company we also worked with in the industry is the end drug shortages alliance, which is the largest industry alliance with a mission to end drug shortages. It has 89 members and I think if you are interested in ending drug shortages, you should be a part of the alliance. You can also support angels for change via our global sharing network. We need manufacturers to be part of this so that we have partners who are ready to help us increase supply and share stewardship of that supply for patients. There is a lot of work happening, policy work both at the administration and in Congress around shortages that hadn't been active before. We need to do that collaboratively, working together.

Then what can you do internally? Here's the question: do you have more policies and procedures in your organisation around budgeting and lowering the cost of care than you do around ensuring access of care?

Then there's some work for you to do. This is a balance and we are all here to ensure patient access and yes, we need to ensure quality and safety. We need to make sure that's affordable, absolutely, but if we're not also putting in the practices that make sure it's available every single day, every single time without fail, individually as a stakeholder, you do have some work that you can do, but I would love to do it with you. So that's where I'm happy to help. We don't have to do it alone. We can do it all together.

I'm not saying any of this is easy, but I am saying there are individual things that you can do as an organisation. I think in general individual members can think proactively. How can I better ensure our organisation has a culture of availability and access?

What do you hope to see in terms of the pharmaceutical supply chain in the next 5 to 10 years, where would you like your work to be?

Sometimes I think it's completely possible to end drug shortages and have a more resilient supply chain. So you know, we need more reliability, which means it breaks less. When it breaks, we need to get to a place where we can recover quickly because we have redundancy measures. All of those are completely feasible.

We don't have to reinvent the wheel, it’s not a new problem, so I believe this can be solved in five years,

I would love to say we hit our mission by then.

We end drug shortage and then let's focus on another important access issue that is plaguing healthcare.

Every single stakeholder needs to be focused on ending drug shortages. So the hospital facility and patient impact object shortage could be completely gone and we have the systems in place to be able to know what to do during a time of disruption and then those disruptions will be less and they don't take as long to recover.

I believe that's possible.

If you're attending CPHI North America, make sure to register for Bray's presentation in the Supply Chain Economy Track at the event.

Related News

-

News Technology revolutionising drug substance development: CPHI North America Interview

From one of the content tracks at CPHI North America in Philadelphia, USA, in May, a lightning round talk was presented on 'Combining Biology and Chemistry for Smart Manufacturing', from Masha Kononov, Ingenza. In the following interview K... -

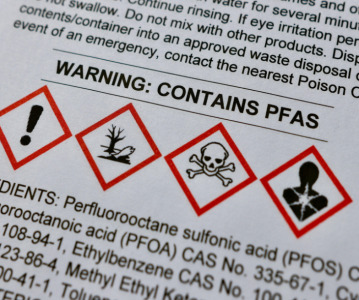

News How are new PFAS regulations impacting excipient manufacture? – CPHI North America Interview

In another interview from CPHI North America in Philadelphia in May, Peter Schmitt from Montesino Associates talks about his presentation on 'Navigating the Waters of Change: The Impact of New PFAS Regulations on the Manufacture of Excipients ... -

News Providing solutions for special populations – CPHI North America Interview

In Philadelphia in May on site at CPHI North America we were able to meet with some of our speakers regarding their presentations. In the following interview Srinivasan Shanmugam, Executive Director, Pharmaceutical Sciences, Business Sup... -

News How tech transfer and process optimisation can help patients – CPHI North America Interview

Following a successful few days in Philadelphia for CPHI North America, I was able to discuss some of the sessions with our expert speakers, gaining a little more insight into the key topics from the event. -

News CPHI North America 2024 – From the Floor

Welcome to Philly! CPHI North America once again graces the Philadelphia Convention Center, 7–9 May 2024. -

News On Track at CPHI NA 2024: Supply Chain Economy with US Pharmacopeia

On the 7–9 May 2024 in Philadelphia, CPHI NA will be presenting an unmissable agenda, filled with content across 4 main tracks. In the following interview the Supply Chain Economy Track sponsor, the US Pharmcopeia introduces the track, and w... -

News Women in Pharma: Diversi‘tea’ at CPHI North America

CPHI North America will unite the pharmaceutical supply chain in Philadelphia from May 7–9, 2024 for 3 days of innovation and connections. As part of the content Agenda, our Diversity Track will bring the industry together to discuss the imperati... -

News On Track at CPHI NA 2024: Sustainable Futures with Thermo Fisher Scientific

On the 7-9 May 2024 in Philadelphia, CPHI NA will be presenting an unmissable agenda, filled with content across 4 main tracks. In the following interview the Sustainable Futures Track sponsor, Thermo Fisher Scientific gives an overview of what to expe...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)