Chinese CDMOs legislating for the future

The Chinese pharmaceutical CDMO sector is set for rapid expansion, thanks to major amendments to the country's Drug Administration Law that make outsourcing manufacturing easier

China’s contract development and manufacturing (CDMO) sector is poised for dynamic growth, according to experts who say revised laws will fuel expansion of the industry. The modern Chinese CDMO industry was born in 2015 when the government launched its “Made in China” strategy. The idea was to relax rules on manufacturing to cut the country’s reliance on imports and encourage local drug development and production [1, 2].

New MAH system

More recently China passed amendments to its Drug Administration Law (DAL) that have further impacted CDMOs [3]. The amendments included measures to encourage innovation, improve traceability and reduce drug counterfeiting.

However, the most significant change – at least from a contracting perspective - was the introduction of a marketing authorisation holder (MAH) system modelled on those in the US and EU.

The system links marketing licenses directly to drug products, which allows holders a greater degree of flexibility when it comes to using contract manufacturing services and establishing distribution chains.

Previously, drug approvals in China were contingent on the developer having its own manufacturing capacity in the country. However, the new legislation states that pharmaceuticals made by contractors can be approved [4].

The changes have improved the situation for contractors in China, according to Kevin Huang from Wuxi Apptech Group: “Regulatory reform certainly has significant impact on the drug approval process in China, in the positive way.

“Now we start to see the approval time is reduced and some innovative medicines get approved at the similar time frame, not years later as in the US and EU.”

CDMO Changes

Somewhat ironically, German pharmaceutical firm Boehringer Ingelheim was one of the first companies in the contracting space to benefit from new DAL regulations in China.

Last December, the National Medical Products Administration of China (NMPA) approved BeiGene’s tislelizumab, a monoclonal antibody-based treatment for Hodgkin’s lymphoma (cHL) [5].

The drug is made by Boehringer Ingelheim BioXcellence at its facility in Pudong, Shanghai under a collaboration agreement signed in 2013 [6].

“Compared to Western markets, the Chinese market is evolving [and] more dynamic,” says a BI spokeswoman. “At our site in Shanghai we combine this Chinese dynamic with ‘German’ quality to best serve our clients and in the end patients with unmet medical needs.”

She adds that “the Chinese CDMO market experienced a high-speed development in the past years.

“When we setup the operations in China, the environment was challenging, especially under the regulatory framework at that time as commercial contract manufacturing of biologics was not permitted by NMPA.

“Indeed, the MAH trial project and the DAL revision were big turning points, since these efforts permit biologics contract manufacturing from legal and supervision perspectives.”

International demand

China is an increasingly attractive market for drug companies. Estimates suggest around $130bn is spent on medicines in China each year, with some predicting this will increase to $160bn in the next three years [7].

According to McKinsey, this growth combined with the DAL revisions and government driven expansion of the national reimbursement drug list (NRDL) and essential drug list (EDL) in 2017 and 2018 will see more international drug companies seek to build in China [8].

In this increasingly favourable environment, multinationals are shifting the focus of their China portfolios from mature to innovative products.

The influx of multinational drug companies is likely to further increase demand for China-based contract manufacturing organisations, according to Wuxi’s Kevin Huang: “From our perspective, the CDMO sector is still attracting private investment as investors believe the booming Chinese biopharmaceutical industry would accelerate CDMO growth. “

He adds that “international companies entering the market will face talent competition and localization challenges, in addition it will cost time for them to adjust and build up capability and capacity.”

Covid-19 disruption

The emergence of SARS-Cov2, the virus that causes Covid-19, in Wuhan, China last December had a huge impact on the country [9].

The government’s efforts to contain the spread of the virus saw Chinese citizens confined to their homes and many industries – including the pharmaceutical sector - temporarily suspend or minimize production operations.

The shutdown prompted concerns about the global drug industry’s reliance on CDMOs in China. For example, according to the US Food and Drug Administration (FDA), 13% of brand and generic active pharmaceutical ingredient (API) manufacturers are based in China [10, 11].

Industry expert Fiona Barry, Associate Editor at PharmSource, told us some disruption is inevitable.

“The GlobalData Drugs by Manufacturer database shows that many biopharma companies, including mega caps, have vital manufacturing steps in Chinese facilities and may be affected by the ongoing COVID-19 pandemic,” she says. “This includes both captive capacity and CMO facilities.”

“But we should caution that it is unclear to what extent disruption in China will affect the world’s supply of pharmaceuticals, as other regions, notably India, are increasing their production,” she adds.

Barry explains many firms dual-source, citing AstraZeneca’s Plendil – which is manufactured at plants in Wuxi, China and Stockholm, Sweden – and Zoloft which is made in Dalian, Liaoning, China as well as sites outside China by Pfizer and by CMOs, as an example.

She also points out that “some Chinese factories have returned to normal capacity.”

Pandemic

SARS-CoV2 has now spread around the world, prompting the World Health Organisation (WHO) to declare it a pandemic and many countries to order similar confinement measures [12].

In China, the situation appears to have improved with many industries resuming operations [13].

Those CDMOs able to restart operations and reconnect with customers are likely to see demand increase, says Wuxi’s Huang, arguing that customers will value contractors with robust, resilient systems.

“COVID-19 will not impact CDMO sector in the negative way,” he says. “The disease will actually bring more awareness so leading CDMOs with strong quality system may emerge to get more business.”

This positive take is shared by Boehringer Ingelheim, with the firm’s spokeswoman saying it expects “all activities to be back to normal soon in China.”

CDMO future

Now the new DAL legislation is in place, the success of the Chinese contract manufacturing sector will be determined by the CDMOs themselves and whether they can meet customers’ evolving requirements.

“The future of the Chinese CDMO sector will jointly be shaped by all market players,” says the Boehringer Ingelheim spokeswoman. “Along with the development of the overall Chinese pharma market and the requirements of high-quality drug supply, we view the CDMO industry has no other direction but to keep increasing its operations, quality and compliance levels.”

References

[1] https://www.cittadellascienza.it/cina/wp-content/uploads/2017/02/IoT-ONE-Made-in-China-2025.pdf

[2] https://itif.org/sites/default/files/2019-china-biopharma-strategy.pdf

[3] https://www.xinhuanet.com/english/2019-08/26/c_138339620.htm

[5] https://www.boehringer-ingelheim.com/press-release/biopharmaceuticals-china

[6] https://www.boehringer-ingelheim.com/press-release/biologicalsbeigenendachina

[7] https://global.chinadaily.com.cn/a/201912/20/WS5dfc27a7a310cf3e3557f6da.html

[9] https://www.nature.com/articles/s41591-020-0820-9

[11] https://www.fda.gov/news-events/press-announcements/coronavirus-covid-19-supply-chain-update

Related News

-

News The next 15 drugs up for negotiation with Medicare include several blockbusters

By now, everyone is quite familiar with the drug price negotiations taking place between drug companies and the Centres for Medicare & Medicaid Services (CMS) in the USA as part of measures being taken to reduce the cost of drugs for patients, to make ... -

News PSCI Welcomes Delpharm, Samsung Biologics, and Suven as First Supplier Partners

The pharmaceutical industry continues to evolve with an increasing focus on responsible sourcing, sustainability, and collaboration across the supply chain. Under a new model to recognise suppliers within the pharmaceutical and healthcare industry that... -

News Drug prices agreed upon as part of the US Inflation Reduction Act

The Inflation Reduction Act brought into constitution by the Biden administation in 2022, which proposed a drug price negotiation between the government and pharmaceutical companies, has reached it's first agreement. -

News Eisai Alzheimer’s drug authorised in UK but still faces obstacles

In partnership with BioArctic AB, pharmaceutical company Eisai has been granted Marketing Authorisation by the Medicines and Healthcare products Regulatory Agency (MHRA) for its Alzheimer’s disease drug product Leqembi. -

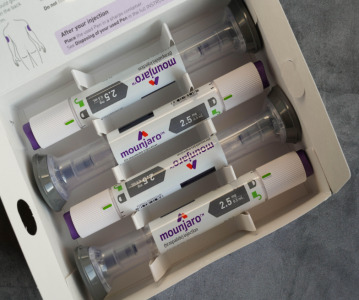

News Eli Lilly's weight loss drugs removed from the FDA's shortage list

The US FDA have recently updated their drug shortage list. The recently released list shows that all dosage forms of Eli Lilly's weight-loss drug Zepbound and their diabetes drug Mounjaro are now available. -

News Global advancements in the diagnosis and treatment of rare diseases: Rare Disease Day 2024

Rare Diseases Day is celebrated on the 29th February 2024 and represents the plight of rare disease patients to gain diagnosis and access to suitable treatment. -

News Pharmaceutical industry supports COP28 health stance in joint statement

As COP28 takes place over this week in Dubai, UAE, several bodies in the pharmaceutical and health industries have come together to announce support of key movements in sustainability in the sector, and to recognise sustainability as a health issue.&nb... -

News Biden backs Cold-War measures to shore-up medical supply chains

In a recent strategy to combat rising inflation and the cost of living crisis, President Joe Biden has invoked a Cold War-era act to increase investment in a selection of medicines and supplies.

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)