Biopharmaceutical packaging

Product Description

Rommelag CMO

-

DE

-

2015On CPHI since

-

3Certificates

-

1000 - 4999Employees

Company types

Primary activities

Categories

Specifications

Rommelag CMO

-

DE

-

2015On CPHI since

-

3Certificates

-

1000 - 4999Employees

Company types

Primary activities

More Products from Rommelag CMO (18)

-

Product Container design

Since the arrival of BFS technology, we have designed thousands of containers for filling volumes ranging from 0.04 ml to 10,000 ml, often in close cooperation with a customer. Many of our packaging solutions have set standards in the market for pharmaceutical products, such as our infusion containers with... -

Product Inspection Systems for BFS containers

With Rommelag’s Cosmetic Inspection system we provide our customers the highest level of control and inspection available. The Cosmetic Inspection machine provides reliable and consistent detection of any formation defects, surface impurities, such as spots, discoloration, imbedded particles, and... -

Product FLECOTEC continuous containment solution

For the many challenges involved in dispensing, discharging, transporting highly sensitive bulk goods, the Flecotec system from Rommelag FLEX has developed an ingenious contained concept that can be ideally adapted to existing processes, requires no recertification and reduces the subsequent cleani... -

Product Process development

Rommelag CMO provides wide range of services which includes process development. It offers production of pilot batches for process development, filtration tests for sterile filtration, scale-up experiments, microbiological tests (internally or in cooperation with external microbiology laboratories), compre... -

Product Rommelag SERVICE

Rommelag offers the system configuration tailored to the product, supports you with the in-house pharmaceutical service already during the planning phase and provides classic after-sales service from installation of the system by our own technicians to maintenance, repair and complex modifications and ... -

Product FLECOTEC continuous containment solution

For the many challenges involved in dispensing, discharging, transporting highly sensitive bulk goods, the Flecotec system from Rommelag FLEX has developed an ingenious contained concept that can be ideally adapted to existing processes, requires no recertification and reduces the subsequent cleani... -

Product Container design

Whether a bottle or an ampoule is to be filled, how it is filled, and what additional functions the container needs are usually based on the intended use. Rommelag’s bottelpack machines can manufacture bottles, tubes, ampoules, drop bottles, bellows containers, unit-dose or multidose containers in a var... -

Product Medical devices and cosmetics

Rommelag CMO provides a wide range of services which includes medical devices and cosmetics. It provides a comprehensive range of services - from research in its own laboratories to consulting in design and material issues. We offer solutions which are developed individually for each product and al... -

Product Packing biotech products

Rommelag CMO has a separate facility for filling all biological pharmaceuticals up to biosafety level 2 (BSL-2) – including active pharmaceutical ingredients (API) such as vaccines and antibodies. This is one of the few blow-fill-seal production facilities in the world to meet this standa... -

Product BFS One-Stop Partner

The Rommelag Group sees itself as a One-Stop Partner for Blow-Fill-Seal Technology and a specialist for flexible Containment Solutions. With our complete solutions for Fill&Finish, we are a strong partner for the pharmaceutical, food, cosmetics and chemical industries. -

Product phamaceutical containers

With BFS technology, bottles, ampoules, dropper bottles and bellows containers can be produced in various shapes and types of plastic. bottelpack lines produce up to 30,000 containers per hour. Classic container volumes range from less than 0.1 ml to more than 1,000 ml. Blow-fill-seal technology is most co... -

Product Contract Filling

Rommelag CMO fills more than 2 million containers a day for customers all over the world. With more than 50 systems in all sorts of configurations, Rommelag CMO runs one of the world’s most cutting-edge and largest bottelpack machine fleets. And they are set up to meet stringent pharmaceutical stan...

Rommelag CMO resources (9)

-

Video Overview Rommelag Pharma Service

This short video explaines shortly what Rommelag can offer you in terms of validation, qualification, training and consultancy.

-

Video Rommelag Pharma Platform (RPP)

The new Rommelag Pharma Platform, RPP, is the basis for digitalizing your bottelpack BFS aseptic filling system for the next generation of pharmaceutical manufacturing.

RPP comes with a detailed information model, granting access to a wide array of possibilities for leveraging data and integrating third-party tools. By networking your bottelpack machines with your shop floor, office, and the Rommelag Service Center, RPP helps you streamline your production and maintenance processes for better decision making and real-time monitoring.

-

Video Introduction to bottelpack advanced aseptic packaging

This short video gives you a short introduction on Blow-Fill-Seal technology (BFS). BFS aseptic filling systems offer unique container designs. Whether bottle or ampoule, various caps and closures or additional functions, the possibilities are nearly unlimited. Rommelag's bottelpack machines can manufacture bottles, tubes, ampoules, bellows containers, and portion packaging in various forms and plastic blends, with filling volumes ranging between 0.1 and 10,000 ml – fully automatically and without human interference. -

Brochure Rommelag Group Overview

One-stop partner for Blow-Fill-Seal technology and specialist for flexible containment solutions. -

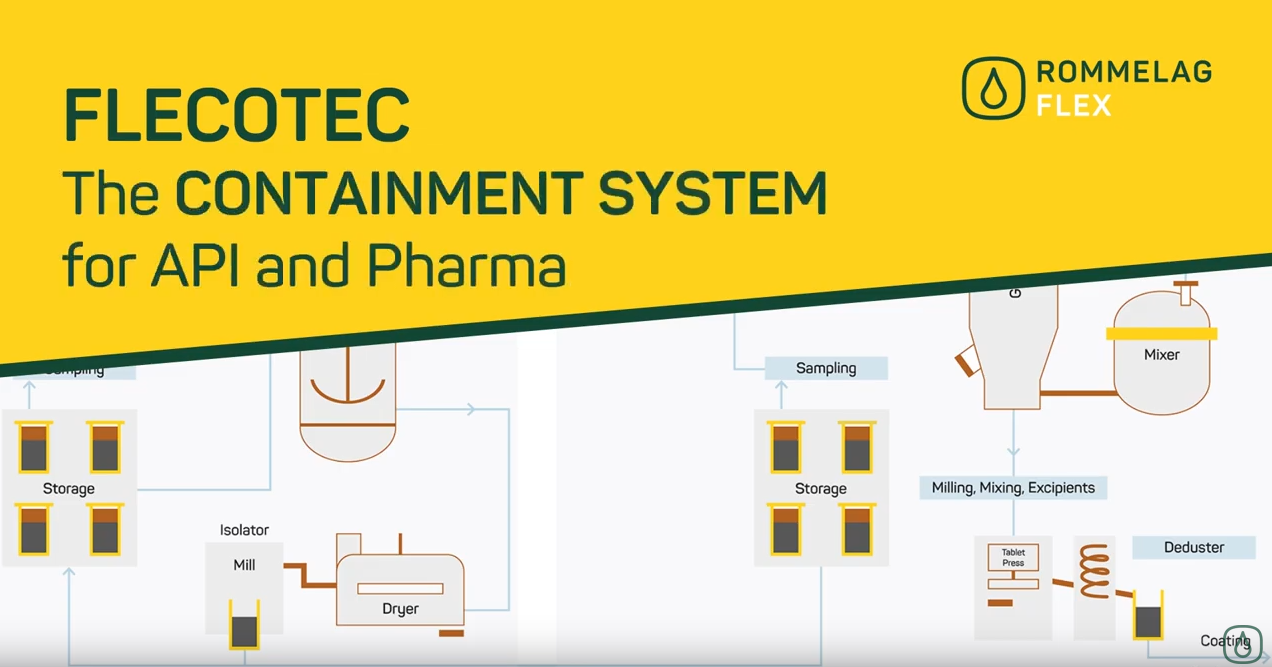

Video Rommelag Flex - your partner for sophisticated containment solutions in the pharma industry

For the many challenges involved in dispensing, discharging, transporting highly sensitive bulk goods, the Flecotec system from Rommelag FLEX has developed an ingenious contained concept that can be ideally adapted to existing processes, requires no recertification and reduces the subsequent cleaning effort to a minimum. The innovative Flecotec system can be used in many areas. It meets the OEB 5 containment level requirements for handling and packaging hazardous raw materials and HPAPI`s. Classic applications are the sampling and dispensing of powders and bulk goods, the sampling in the process or the emptying and filling of bags, for example in the API or tablet production.

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance