Introduction to bottelpack advanced aseptic packaging

This short video gives you a short introduction on Blow-Fill-Seal technology (BFS). BFS aseptic filling systems offer unique container designs. Whether bottle or ampoule, various caps and closures or additional functions, the possibilities are nearly unlimited. Rommelag's bottelpack machines can manufacture bottles, tubes, ampoules, bellows containers, and portion packaging in various forms and plastic blends, with filling volumes ranging between 0.1 and 10,000 ml – fully automatically and without human interference.

Rommelag CMO

-

DE

-

2015On CPHI since

-

3Certificates

-

1000 - 4999Employees

Other Content from Rommelag CMO (8)

-

Video Overview Rommelag Pharma Service

This short video explaines shortly what Rommelag can offer you in terms of validation, qualification, training and consultancy.

-

Video Rommelag Pharma Platform (RPP)

The new Rommelag Pharma Platform, RPP, is the basis for digitalizing your bottelpack BFS aseptic filling system for the next generation of pharmaceutical manufacturing.

RPP comes with a detailed information model, granting access to a wide array of possibilities for leveraging data and integrating third-party tools. By networking your bottelpack machines with your shop floor, office, and the Rommelag Service Center, RPP helps you streamline your production and maintenance processes for better decision making and real-time monitoring.

-

Brochure Rommelag Group Overview

One-stop partner for Blow-Fill-Seal technology and specialist for flexible containment solutions. -

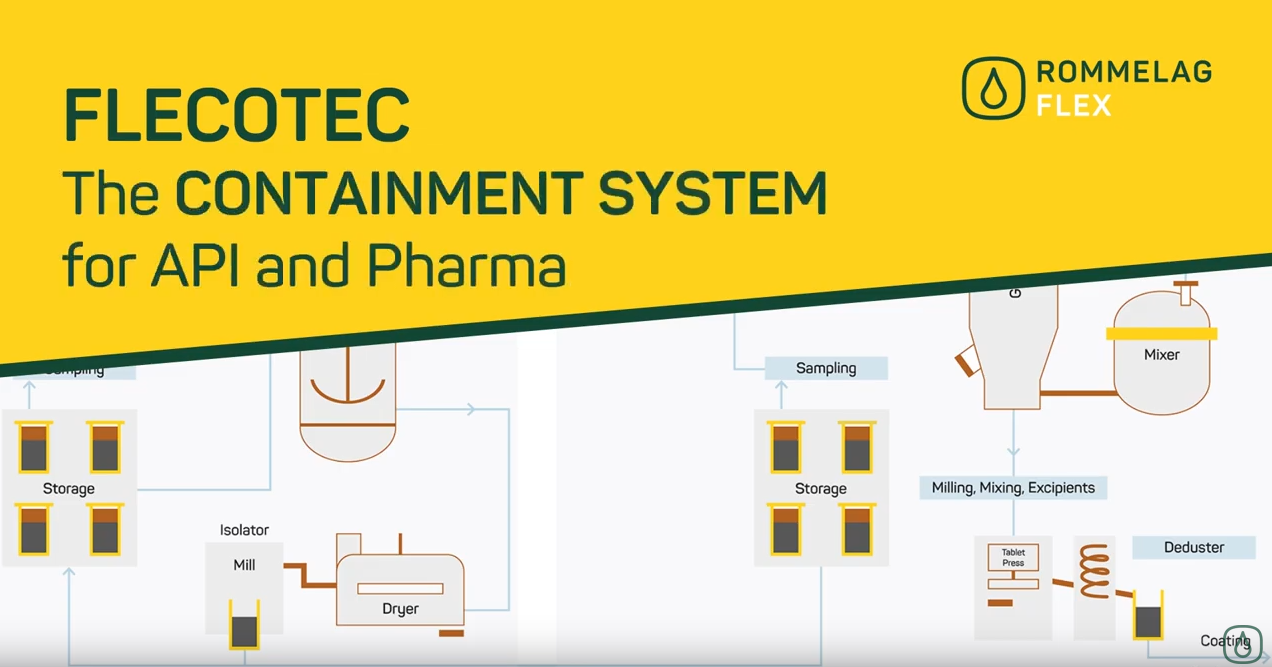

Video Rommelag Flex - your partner for sophisticated containment solutions in the pharma industry

For the many challenges involved in dispensing, discharging, transporting highly sensitive bulk goods, the Flecotec system from Rommelag FLEX has developed an ingenious contained concept that can be ideally adapted to existing processes, requires no recertification and reduces the subsequent cleaning effort to a minimum. The innovative Flecotec system can be used in many areas. It meets the OEB 5 containment level requirements for handling and packaging hazardous raw materials and HPAPI`s. Classic applications are the sampling and dispensing of powders and bulk goods, the sampling in the process or the emptying and filling of bags, for example in the API or tablet production.

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance