22

Jan

2025

Dec Group

Exhibitor at Pharmapack Europe 2025 stand C10

About Us

Categories

-

CH

-

2020On CPHI since

-

4Certificates

-

500 - 999Employees

Company types

Primary activities

Event information

Pharmapack Europe 2025

-

22 Jan 2025 - 23 Jan 2025

-

Paris Expo, Porte de Versailles - Hall 7.2 | Paris, France

-

Visit us at stand C10

Products Featured at Pharmapack Europe 2025

-

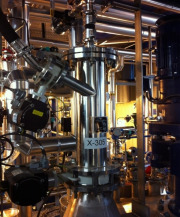

Product DecFill® Aseptic Filling Solutions

DecFill® solutions are configured to meet a wide range of product and customer requirements. These include de-bagging, de-lidding and de-nesting units and various other options to accurately fill liquids, powders and gels into the various containers.To ensure highest process performance within a controlled... -

Product MC DecJet® Spiral Jet Mills

The new 4th generation MC DecJet® systems stand for: • Narrow Particle Size Distribution (PSD)

• Simple and rapid assembly/disassembly • Limited number of components • High yields • Low energy consumption • Sterile manufacturing • PSD scalability with all MC DecJet® models -

Product Process Isolator Technology

Dec develop, design and supply turnkey process integrated containment technology solutions for both potent and aseptic materials. -

Product PTS Powder Transfer System®

PTS is a significant enhancement to any process, providing total containment where necessary, but always speeding up production whilst improving safety and hygiene.

Batch times are substantially reduced and existing process steps are linked to each other.

Dec Group Resources (1)

-

Brochure Trusted Leader in Process Containment

Powder Handling, Processing and Containment for Pharmaceutical Manufacturing True end-to-end solutions for batch and continuous processing

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance