- Home

- STE TECPHARM, S.L.

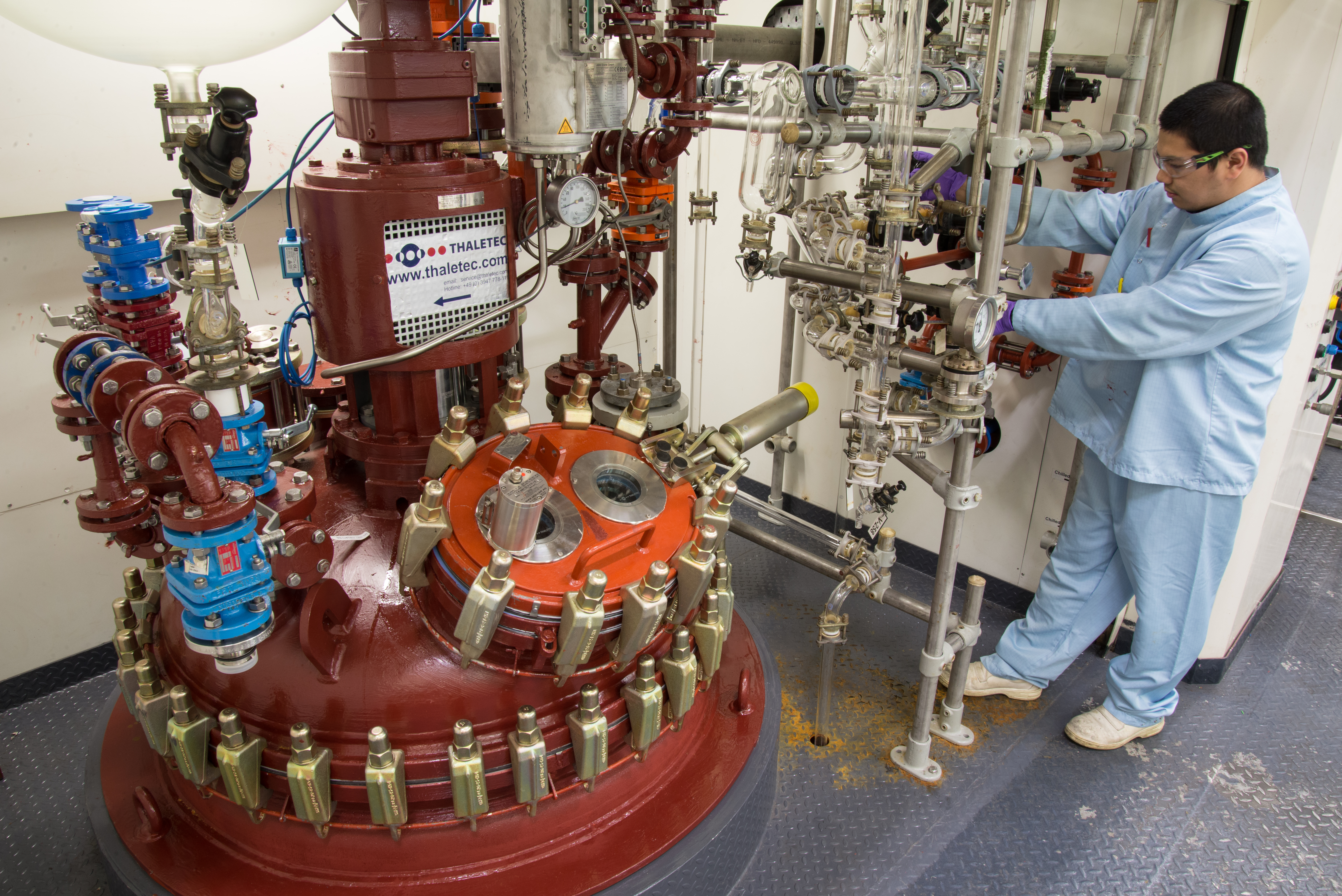

- 1. TP G - High Shear Mixer Granulator

CPHI Online is the largest global marketplace in the pharma ingredients industry

-

Products0

-

Companies0

-

Articles0

-

Events0

-

Webinars0

1. TP G - High Shear Mixer Granulator

Product Description

It has been designed for the optimization of a wet granulation process. Used to turn a heterogeneous mixture of fine powder into a uniform granulation with an increase of the particle size and density. Moreover, it improves the fluidity of the product and its compactness properties, within a short process time and with repeatability.

Main Features:

- Standard capacity: 25 L to 1.400 L.

- It has a bottom impeller and a side chopper to guarantee an intensive mixing within a short time period. It includes accessories allowing to control the granulation end point by Time or by Torque.

- No contact top cover without supports in the container.

- Includes all the clamp connections for the required functions (vent, spraying, raw material loading, inertization, cleaning ball…).

- Sight glass.

- PLC + HMI for the control of the equipment in manual and automatic mode, with recipe editing.

- All critical parameters are controlled by the automat throughout the process.

- Automatic lift of the impeller to ease the cleaning.• WIP accessories.

- "In wall" design to be completely integrated in the clean room.

- Working platform adapted to the client room.

STE TECPHARM, S.L.

-

ES

-

2016On CPHI since

Contact info

-

-

-

Avda.Universitat Autonoma 13, Parc Technologic del Valles, 08290, Barcelona, Spain

Categories

Specifications

- Supplied fromSpain

Sales Markets

- Middle East Region (e.g. UAE)

- Africa

- Central America (e.g. Mexico)

- East Asia (e.g. China, Japan, Korea)

- Europe - EU countries

- Europe - non EU (e.g. UK, Russia, ex-CIS countries)

- South America (e.g. Brazil, Colombia)

- South Asia (e.g. India, Pakistan, Sri Lanka)

- South East Asia (e.g. Thailand, Philippines, Singapore)

STE TECPHARM, S.L.

-

ES

-

2016On CPHI since

Contact info

-

-

-

Avda.Universitat Autonoma 13, Parc Technologic del Valles, 08290, Barcelona, Spain

More Products from STE TECPHARM, S.L. (2)

-

Product 2. TP S - Fluid Bed Dryer

Designed to perform 3 different processes:

• Drying of wet granulate

• Top drive granulation

• Bottom spray coating for micro granules

Main Features:

• Standard capacity: 30 L to 1.540 L. • PLC + HMI for machine control i... -

Product 3. TP R - Perforated Pan Coating

The perforated pan coating is an equipment based on a film coating for tablets and production of pellets. Its high technology allows an automatic flow control, avoiding the damp, saving coating and optimizing the process time.

TP R COATER | Main features: • Standard capacity: 5Kg ...

Recommended Products

-

Product EVO Flex Rotary

High flexible assembly platform

The ideal platform for assembling large numbers of medical devices with limited numbers of components like pens, auto-injectors and inhalers. Fully electronic, it’s quick to install, easy to configure and the best way for the market to respond to customers...

-

Product Milling and Micronization

Milling and micronization with air jet mills, mechanical and cryogenic mills, in strict compliance with cGMP guidelines. Micronization processes can be combined with (fractionated) sieving, blending and homogenization. With dedicated clean room systems, we can micronize HAPI, hormons, controlled drugs and ...

-

Product Humodar C25 100 R

PRJSC "Indar" provides wide range of insulin products in vials and cartridges which includes humodar c25 100r. Its an anti-diabetic product of short effect. Ensures quick decrease of glucose level in the blood, intensifies its absorption by tissues. The effect starts after 30 minutes and can last within 5-...

-

Product ANTACID GUM

Double action Chewing gum: antacid and protective. Useful in case of symptoms associated to laryngopharyngeal reflux. Prompt relief, sustained protective action.

-

Product Contract Formulation

GMP and VMD licensed facilities specialising in formulating including API's.We operate a full pharmaceutical quality system with the support of a QP and several contract laboratories.

Formulation is not just about achieving the right blend of chemicals it is about having the experience to achieve the ri...

-

Product MINI-PACTOR®

The Pactor series of Roller Compactors is perfectly suited to meet and exceed your dry granulation process requirements. Patented force controls and feed design minimizes scale-up efforts and allows the machine to compact and mill pharmaceutical products with poor flow characteristics. R&D and ...

-

Product FLUOLEAD

Innovative nucleophilic fluorination agentBest alternative to DAST, Deoxo-fluor,... Ketone (non-enol form) and carboxylic acid can be fluorinated HIgh thermal stability Easy to handle (solid product) Only 1 step needed for deoxo-fluorination

-

Product LYOVAC ECO Mode

LYOVAC ECO Mode: a solution for tomorrow

With a focus on saving both energy and media, GEA’s new LYOVAC® ECO Mode combines dynamic condenser temperature control and mushroom (chamber/condenser) valve regulation to optimize the lyophilization process.

Our new algorithm changes the set point ...

-

Product Packaging, Quality Control, Storage, Cold Chain

Within the contract development and manufacturing, IDT Biologika GmbH provides a wide range of other pharmaceutical services for our clients products, which include- Labeling & Packaging of vials, prefilled syringes, autoinjectors - Serializiation (Track & Trace) - Quality Systems - Cold Chain up to - 80- ...

-

Product ISOGuard Glovebox Gloves

The glovebox glove TRON 1000 ISOGUARD is an excellent glove, its Viton layer has good resistance to halogenated hydrocarbons, aliphatic and aromatic hydrocarbons, such as benzene, toluene, xylene, trichloroethylene, perchloroethylene. Its butyl layer has good resistance to polar hydrocarbons, such as keton...

-

Product ADC & Bioconjugation CDMO services

With 15+ years of contract development and manufacturing experience, Millipore® CTDMO Services offers leading expertise in the conjugation of drug linkers to monoclonal antibodies (mAbs). As ADC and Bioconjugation CDMO, we have comprehensive experience in conjugation technologies backed by broad analytical...

-

Product CordenPharma Oligonucleotide Platform

Your Expert Partner for Oligonucleotide APIs

• Process Development & Small-scale: scale-up to 10 mmol per run(small-scale equipment can also support early-stage supply)

• Scale-up & Small to Medium-scale: scale-up to 100 mmol per run(supported by OligoPilotTM equipment)

• ...

-

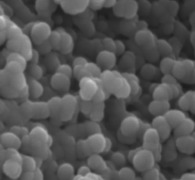

Product Nanoparticles

Particle Engineering Technologies

We specialize in particle engineering technologies to address oral bioavailability, lung delivery, modified release and taste masking. In each technology we can support you from proof of concept to commercial manufacturing.

Nanoparticles

At Hovione we ...

-

Product Zeta - Pharmaceutical freeze drying systems

For GMP processes in pharmaceutical applications, we offer the Zeta freeze dryer series featuring the dual-chamber principle. The big integrated intermediate valve separates the two parts: product chamber and ice condenser. The large opening provides ideal flow conditions for water vapour. The dual-chamber... -

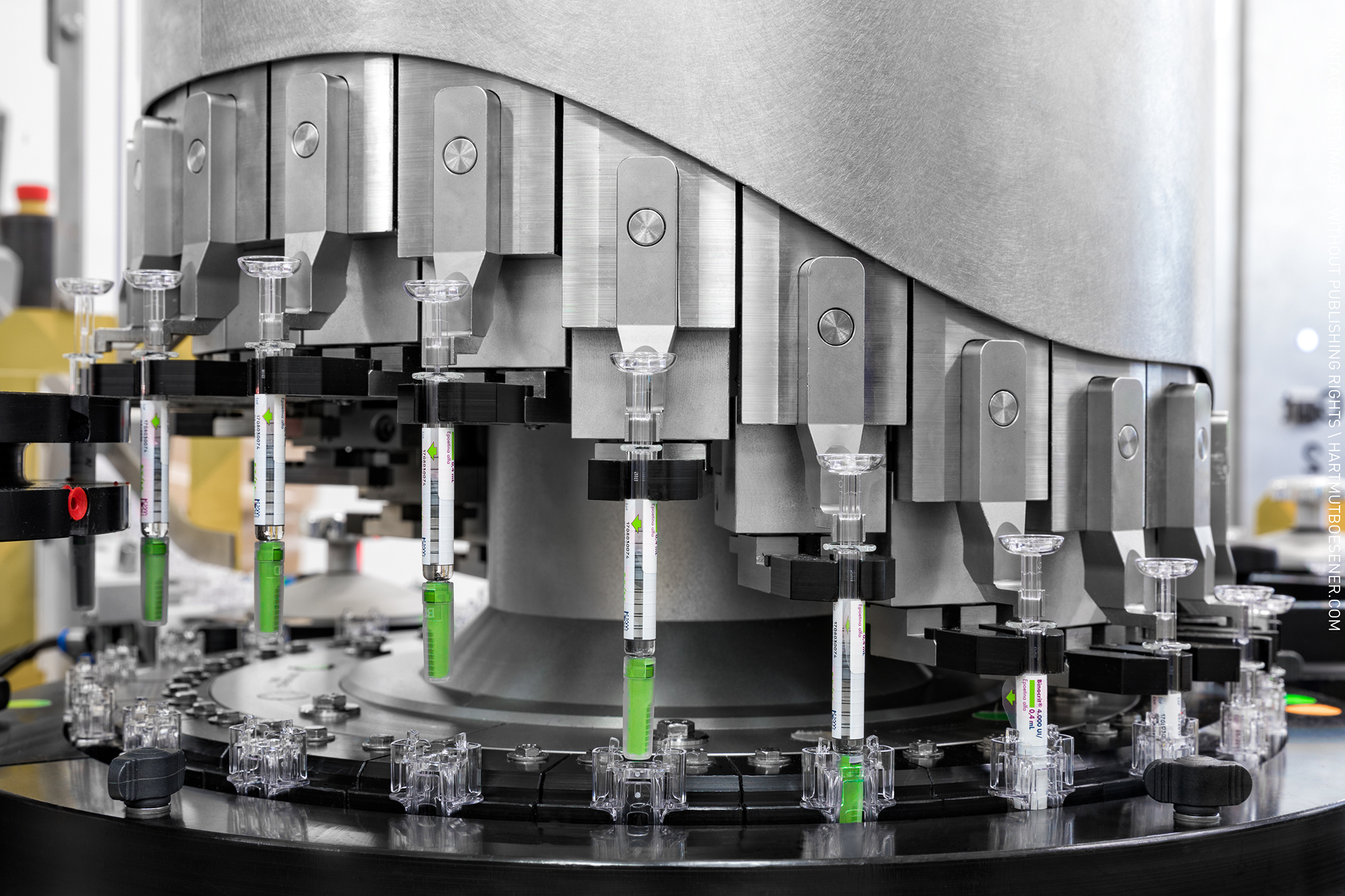

Product Biologic drug product CMO services - Fill and Finish

GC Biopharma is one of the top-tier biopharmaceutical companies in South Korea with over 55 years of history and advanced technology. GC Biopharma provides premium Fill & Finish service to clinical and commercial customers for vaccines, recombinant and biosimilar pharmaceutical products. We have state-of-t...

-

Product API Services, Chemical Development & Manufacture

Almac’s strength in API development and manufacture is proven by being the partner of choice for many pharma and biotech companies seeking integrated drug development solutions from molecule to market.

Our technical expertise and extensive facilities enable us to offer integrated API contract ma...

-

Product Vibratory Feeding System for Tablets & Capsules

Integrates seamlessly with Ackley printing & laser production machinery. Uses precise vibrations to convey tablets, capsules or confectionery product from one piece of equipment to the next. Crafted of stainless steel with a clear acrylic lid, this sturdy system keeps pharmaceutical and nutrac...

-

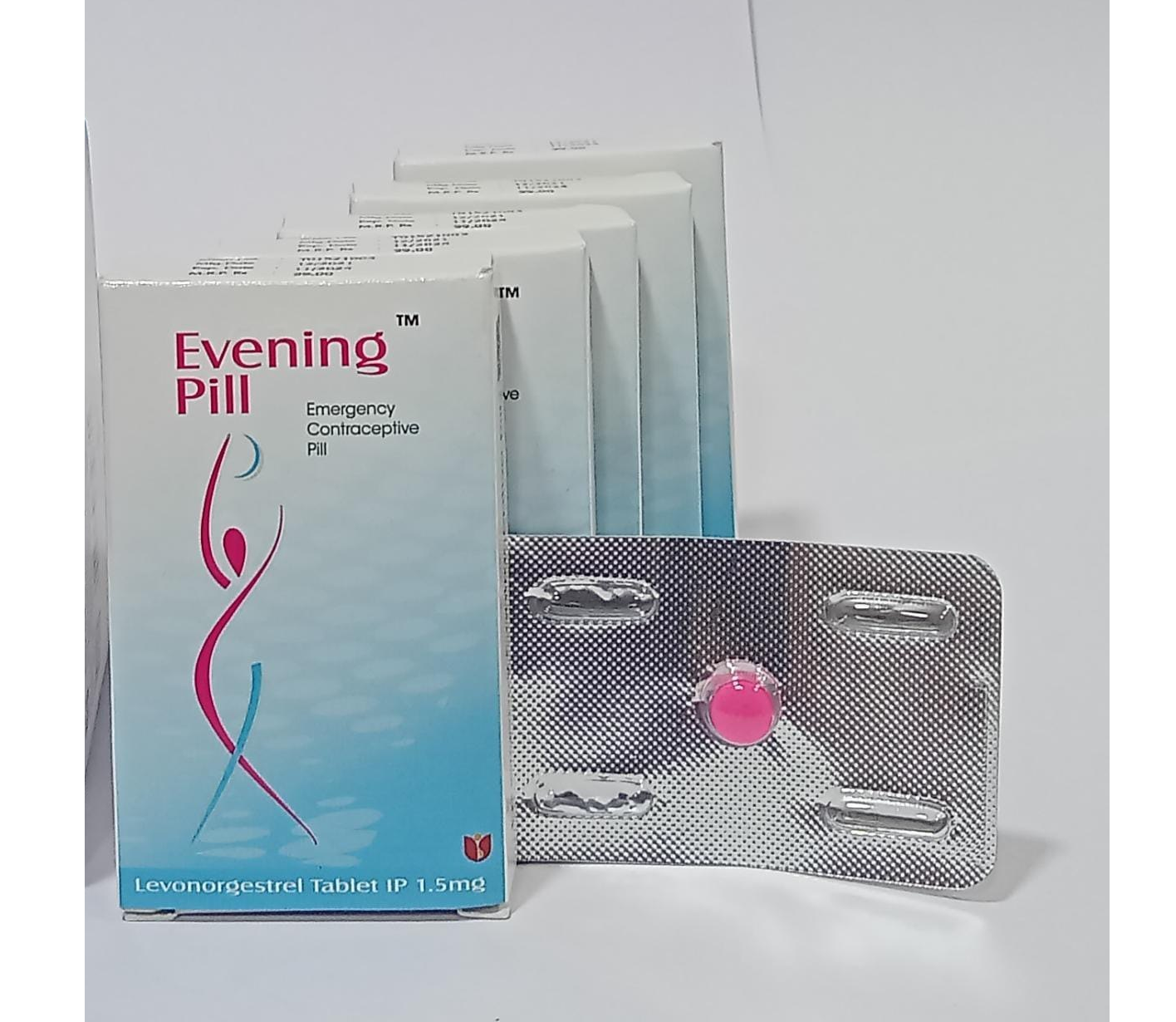

Product Levonorgestrel Tablet 1.5 mg-Evening pill

The Emergency Contraceptive Pill for Safe Desire

Shree Venkatesh International Ltd offers a wide range of pharmaceutical products, including Levonorgestrel 1.5 mg Tablets.

• Use: The Evening Pill is an emergency contraceptive pill that helps prevent pregnancy after unprotected s...

-

Product ATS SuperTrak – Asynchronous Linear Conveyance Platform

SuperTrak CONVEYANCE™ products include, SuperTrak GEN3™ and SuperTrak MICRO™ conveyors. SuperTrak GEN3™ and SuperTrak MICRO™ are smart enabled technologies that get machines to production faster and more effectively than traditional methods by saving significant engineering and int...-comp306932.png)

-

Product Good manufacture practice – Safety for products with biologically active...

When adding substances that have an impact on the human organism, strict legal and hygienic requirements do apply.

In addition to high-precision cooking, dosing, cooling and moulding processes, these products require a suitable GMP concept (good manufacture practice) for the entire pla...

-

Product ATS Symphoni – Synchronous High Performance Digital Assembly Solution

Our ATS Symphoni is a digital assembly automation technology featuring an unmatched combination of speed, versatility, and precision. It delivers business value in a scalable, modular platform that merges the best features from each – the digital flexibility of robotics and linear motio...-comp296617.jpeg)

-

Product Aseptic Isolators for Sterile Applications

FPS sterile containment systems maintain a sterile environment around processes, requiring minimal space and eliminating the necessity for sterile cleanrooms.

Our custom isolators are meticulously engineered to meet the highest pharmaceutical standards, ensuring impeccable sterile co...

-

Product ASYMMETRIC HYDROGENATION

We extensively address the specific needs of the pharmaceutical, food, cosmetics, agrochemicals and specialty chemicals industries with our capabilities in Transition Metal Catalysis (TMC) as applied to asymmetric hydrogenation. Complex active pharmaceutical ingredients (API’s) are often stereochemica...

-

Product Spinal cannulas

sfm medical devices gmbh offers wide range of products which includes spinal cannulas. It belongs to neurology / regional anesthesia / pain therapy category. The special geometry of the cannula tip ensures a higher stability in the penetration of the dura mata. At the same time, the appropriate pencil poin...

-

Product Medical pharmaceutical devices

Gofarm is an expert in medical pharmaceutical devices. The group of medical devices includes not only plasters, implants, diagnostic tests or devices for monitoring the health of patients, such as ultrasound. Among these products there is a group of pharmaceutical medical devices, which, thanks to their m...

-

Product HPAPI handling & processing

Highly potent and toxic substances (OEB 3 – OEB 6) are handled using high-tech containment technology and processes which are OHSAS 18001 certified.

-

Product Autoinjectors & pens

Proven track record in managing parenteral customized solution and large scale industrialization projects of Autoinjectors and Pens with top pharmaceutical companies.

Our offer:

- disposable & reusable pen injectors

- Taylor-made autoinjectors & pens

-

Product Tablet /Capsule Auto Inspection Machine

PLANET EV is an automatic sorting machine that inspects the surface of tablets and capsules using a camera, then sorts them into "good" or "defective".It's precise and high-speed inspection addresses the limitations of manual visual checks.

The EV is also known for its stability and flexibility, making ...

-

Product CONTRACT DEVELOPMENT

Comprehensive single-source provider from drug product development through commercial manufacture:

we offer a complete service including regulatory strategy evaluation, formulation development, scale up, manufacturing process validation, analytical methods development and validation, I...

-

Product Intermediate Bulk Container and tablet- and capsule containers

Blending and storage containers and tablet and capsule containers

At L.B. Bohle we have containers for every feasible use: Transport and storage containers, blending containers, stainless steel containers, round or square, different cone angles, for mass flow, drums

mobile and s...

-

Product Zinc Oxide Mousse

Zinc Oxide Mousse: protects & hydrates. Soothes dry, itchy and red skin irritations.

-

Product Smart_Projector_Double Pharma

Double Magnification Video Measuring Instrument for Primary Pharmaceutical Packaging: Smart_Projector_Double Pharma allows automatic, objective, repeatable, easy and fast dimensional quality check of a wide range of items.

Two in One

Smart_Projector_Double Pharma is a digital Profile Projector ...

-

Product Pharmaceutical Shock Freezer TPSU 1000 (-40°C to -85°C)

Thalheimer has innovated the new technology and production of the fastest Pharmaceutical Shock freezer down to – 85ºC in cooperation with specialist in the fields of Pharmaceutical manufacturers and thermodynamics. All units are complied with UNI EN 61010-1/A2 (CEI 66-5), CEI EN 61326-1, Regulations on saf...

-

Product Amoxicillin and Potassium Clavulanate Tablets - Finemox CV

Amoxicillin and Potassium Clavulanate Tablets combine an antibiotic (amoxicillin) with a beta-lactamase inhibitor (potassium clavulanate).

Indication - To treat bacterial infections by killing bacteria and enhancing the antibiotic's effectiveness against resistant strains. The combination is use...

-

Product Complete Injectable Liquid/ Dry Powder Vial Packaging Line

Harikrushna Machines' Injectable Liquid/ Dry Powder Vial Packaging Line for filling 2 ml to 100 ml vials with up to 400 vials per minute Complete Dry Powder Filling Line consists of a Rotary Vial Washing Machine/ Linear Vial Washing Machine, Sterilization and depyrogenation Tunnel, Auto...

-

Product M3DIMAKER pharmaceutical 3D printers

The M3DIMAKER is the world's first GMP-ready pharmaceutical 3D printer series with in-built quality control features and exchangeable printheads for fully personalised human and veterinary precision medicine manufacture. Our printers can be used under extemporaneous/compounding preparation regulation using...

-

Product Isolation technology

Getinge's barrier isolators create a separation of raw materials, a product or an experiment from its environment. The patented DPTE® sterile transfer systems provide the means to move material in and out of an isolator or sterile zone without breaking containment.

Getinge developed the ISOFLEX-R isol...

-

Product Filling Line Isolator

Filling lines enclosed in an isolation technology are now widely utilized for the aseptic manufacture of sterile pharmaceuticals in various container formats.

Esco Pharma’s filing line isolator provides an ISO Class 5 / Grade A environment, ensuring the sterility of the work zone for the most de...

-

Product ARTISAN ROTOTHERM®

ARTISAN ROTOTHERM® Horizontal, agitated thin-film evaporator

Concentrate heat sensitive API’s, viscous, foaming and fouling materials from high moisture content in a single step.

Applications include:

• Concentrating heat-sensitive APIs • Visco...

-

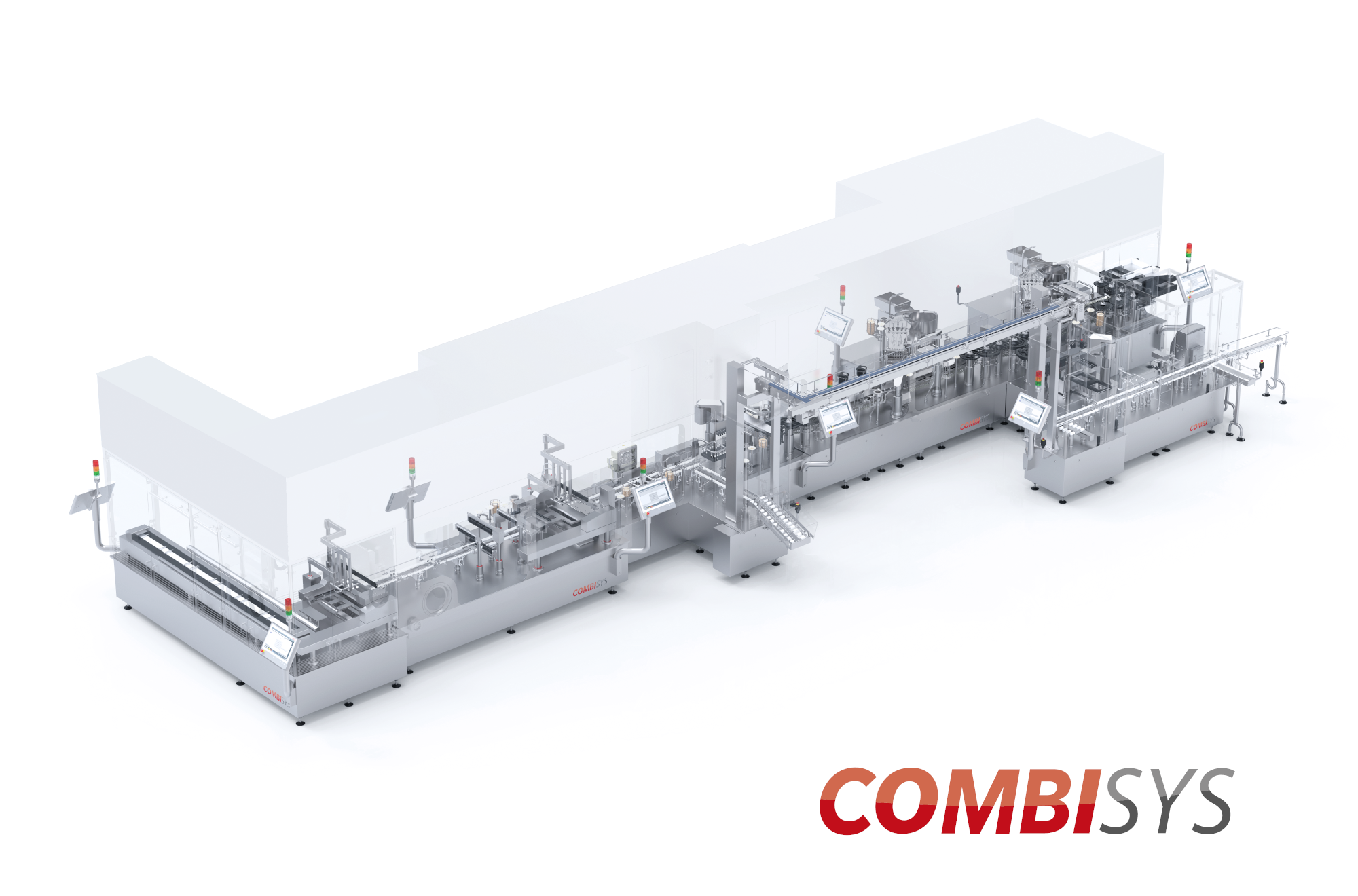

Product CombiSys

// Flexibility meets zero reject principle. ///

CombiSys is an efficient and highly productive system solution that enables you to process various packaging materials on a single platform. The transport system uses grippers that give you a wide working range without changing size parts. Modul...

-

Product STEP T700 TABLET PRESS MACHINE

Application

● Level 3 safety circuit, safe operation

● High precision manufacturing, reliable operation

● Modular design, easy to disassemble

● High Performance PLC + Industrial computer control

● Servo motor adjusts pressure and filling depth

...

-

Product Managed Markets Data & Analytic Solutions

Fundamental to the success of your market access strategy is clear visibility into payer, provider and patient behavior. IQVIA’s comprehensive real-world database includes lifecycle transactions, which offer the critical level of detail required to untangle the complex interaction of payer utilization mana...

-

Product ProMoCurve - Assembly platform for medical equipment

The ProMoCurve from Strama-MPS is an assembly platform for a wide variety of consumables in the life science industry, such as

inhalers, insulin pens, lancing devices or laboratory disposables. It is based on a modular platform that can be expanded almost at will.

This means that we a...

-

Product improve immunity, antifatigue softgel/soft capsule

The advangates of softgel dosage

Better Bio-availability

Higher absorption rate

Easy to swallowCoenzyme Q10 helps with myocardial energy metabolism: it can activate myocardial mitochondria to synthesize ATP and help inhibit the release of myocardial enzymes into...%20(1)-comp286402.jpg)

-

Product PROCESS INSTRUMENTS

Radix Instruments are considered reliable by our customers in the pharmaceutical industry which is governed by the most stringent regulations and sets the standard for instrumentation quality. Our products will meet and exceed your expectations for process instrumentation.

Radix Instrum...

-

Product ready to fill 5ml tubular glass vial for injection

1)ZCP is China's Top 2 pharmaceutical primary packaging material producer and the BlGGEST tubular vials manufacturer in China.

2) ZCP is a publicly listed company in China, Stock code:603976.

3) ZCP was founded in 1988, and most of th...

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance