Twin-screw extrusion - hot melt extrusion

Product Description

Xedev

-

BE

-

2016On CPHI since

-

1Certificates

-

1 - 24Employees

Company types

Primary activities

Categories

Specifications

Xedev

-

BE

-

2016On CPHI since

-

1Certificates

-

1 - 24Employees

Company types

Primary activities

More Products from Xedev (10)

-

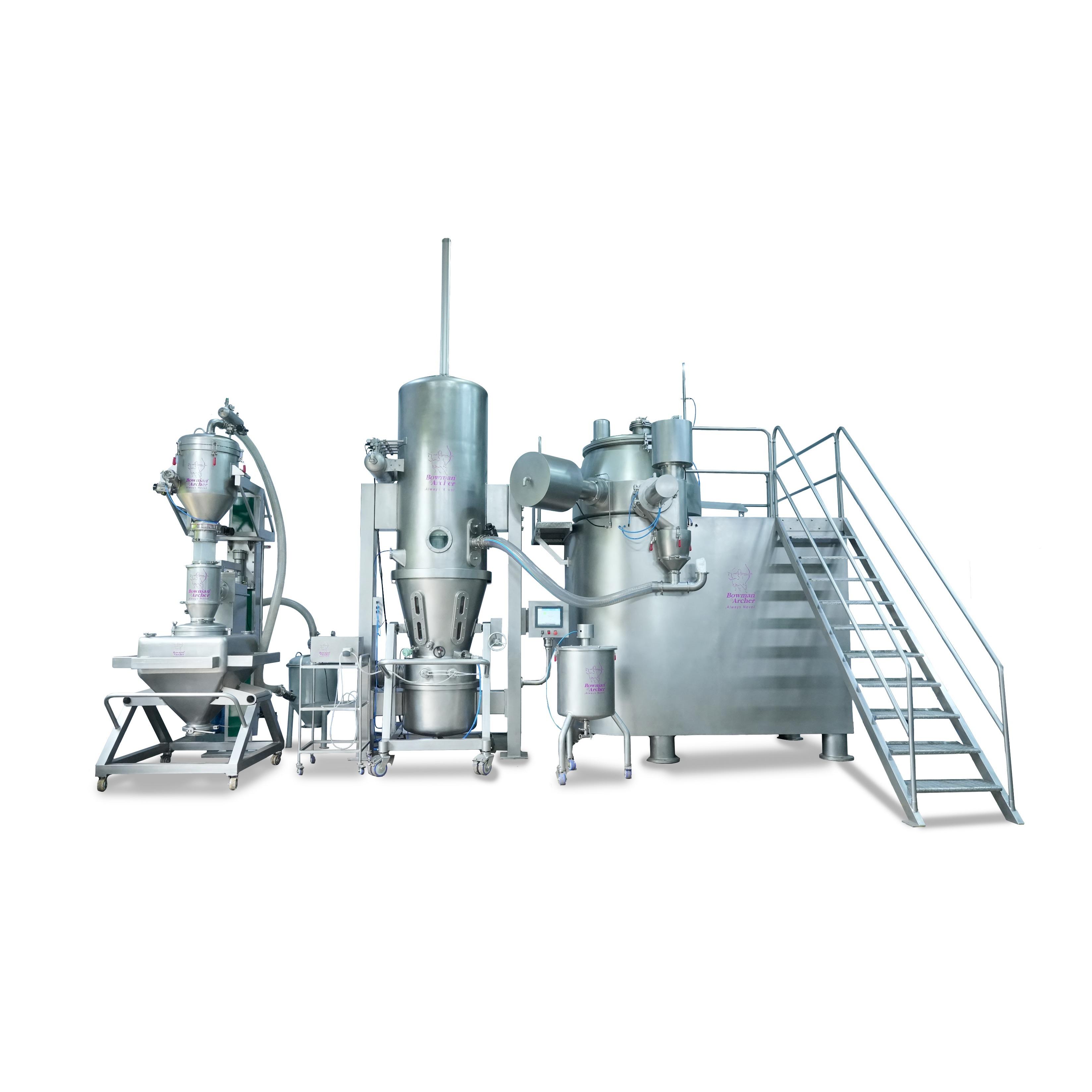

Product Spray-drying

Spray-drying is an instant and continuous solvent evaporation process of a liquid feed, atomised in a heated gas, generating a final dried solidified particle.The heated drying gas moves in co-flow with the atomised feed in the process chamber where the gas transfers its heat energy to the droplets and abs... -

Product Formulation and process development

Do you have an NCE that needs to be formulated in a solid dosage form or having challenging process and formulation questions, then XEDEV is your partner to assist you, as we are specialised in formulation and process development through drying, granulation, tableting and/or coating processes.

P... -

Product Development Oral Solid Dosage forms

XEDEV provides wide range of technologies going from powder to tablet in order to develop your final oral solid dosage form. • spray-drying • encapsulation • granulation (wet, dry and hot) (batch and continuous) • tableting • coating Contact us for more information. -

Product Analytical package

XEDEV provides a broad range of analytical tools including : • Solid state analysis: mDSC, XRPD, PLM, TGA, FTIR, RAMAN • Powder characterisation : SEM, PSD (both wet and dry), flowability • Tablet characterisation : friability, disintegration, hardness, dissolution • Residual solvent determination :... -

Product Fluid bed dryer/coater/agglomerator

Xedev provides wide range of technologies which includes fluid bed dryer/coater/agglomerator. Contact us for more information. -

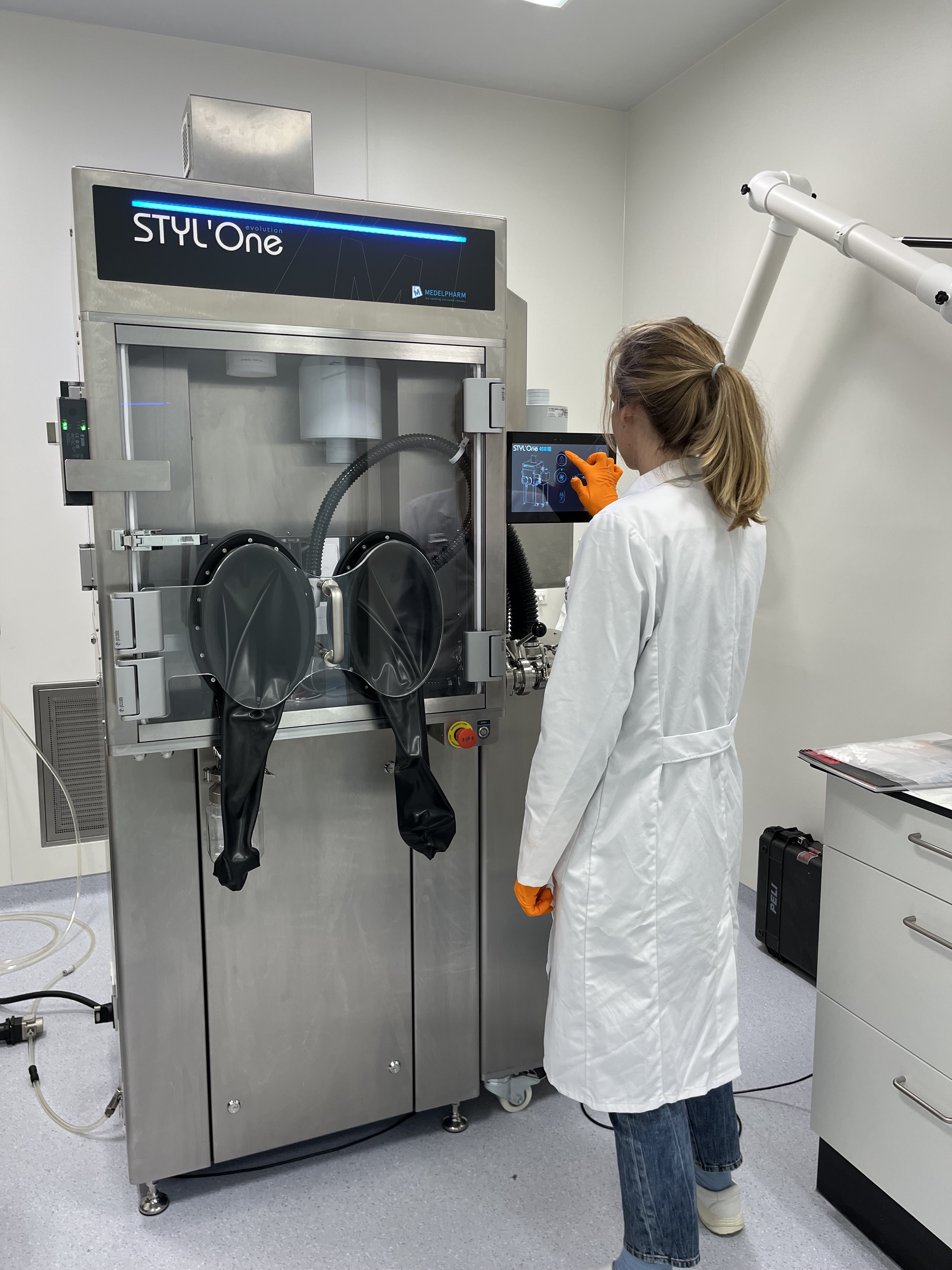

Product Hot melt twin screw extruder

Xedev provides wide range of technologies which includes hot melt twin screw extruder. Contact us for more information. -

Product Perforated drum tablet/capsule coater

Xedev provides wide range of technologies which includes perforated drum tablet/capsule coater. Contact us for more information. -

Product Agitated vaccum dryer

Xedev provides wide range of technologies which includes agitated vaccum dryer. Contact us for more information. -

Product CDMO services - Spray-drying

Xedev can perform the clinical production for your spray-drying project. -

Product Clinical batch production

XEDEV can support clinical batch manufacturing up to Phase IIb in our clean rooms after succesfull development.

Xedev resources (1)

Frequently Viewed Together

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

-comp245604.png)

-comp306932.png)