To produce biopharmaceuticals on demand, just add water

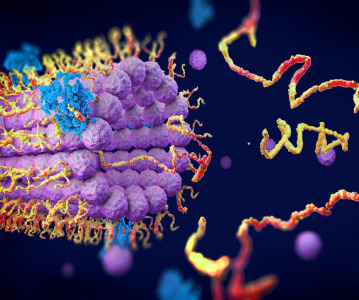

Freeze-dried cellular components can be rehydrated to churn out useful proteins.

Researchers at MIT and other institutions have created tiny freeze-dried pellets that include all of the molecular machinery needed to translate DNA into proteins, which could form the basis for on-demand production of drugs and vaccines.

The pellets, which contain dozens of enzymes and other molecules extracted from cells, can be stored for an extended period of time at room temperature. Upon the addition of water and freeze-dried DNA, the pellets begin producing proteins encoded by the DNA.

“It’s a modular system that can be programmed to make what you need, on the spot,” says James Collins, the Termeer Professor of Medical Engineering and Science in MIT’s Department of Biological Engineering and Institute for Medical Engineering and Science (IMES). “You could have hundreds of different DNA pellets you can add in the field.”

These pellets, a few millimeters in diameter, could be easily carried by soldiers, astronauts, or health care workers heading to remote areas, says Collins, who is the senior author of a paper describing this strategy in the 22 September online edition of Cell.

The paper’s lead authors are Keith Pardee, an assistant professor at the University of Toronto and former research scientist at Harvard University’s Wyss Institute for Biologically Inspired Engineering; Shimyn Slomovic, an IMES postdoc; Jeong Wook Lee, a Wyss Institute research scientist; and Peter Nguyen, a Wyss Institute Technology Fellow.

Cell-free synthesis

Collins and many others in the growing field of synthetic biology have previously designed cells to perform many functions they don’t normally have, such as producing drugs or biofuels. Over the past few years, Collins has shown that this kind of design can also be done outside of cells, by extracting the necessary cellular components and freeze-drying them onto paper or other materials.

“The cell-free extracts consist of a few dozen enzymes, DNA, and RNA, as well as ribosomes and other molecular machines leading to transcription and translation,” Collins says.

In the new study, the researchers took the paper out of the equation: The cellular extracts are simply freeze-dried into pellets, which remain stable for at least a year. To activate protein production, the researchers add water to rehydrate the pellets, along with freeze-dried DNA that encodes the desired protein.

This approach could be useful for generating a wide range of products, including both drugs and molecules that could be used to diagnose illness. In the Cell study, the researchers produced small proteins that could be used as a diphtheria vaccine, as well as antimicrobial peptides, which hold potential to fight bacterial infections.

They also programmed the pellets to generate enzymes that form a multistep metabolic pathway that synthesizes a complex drug known as violacein, which has anticancer and antibiotic activity.

For diagnostic applications, the researchers used the pellets to produce several different types of antibodies, including one that can detect the bacterium Clostridium difficile, which can produce severe inflammation of the colon.

Easy storage

This approach could prove easier than using live cells to generate biopharmaceuticals because the freeze-dried components are easy to store and ship, and they don’t need to be refrigerated.

Collins anticipates that this type of technology should be useful in a variety of settings.

“It could be used in a very simple carry kit for health care workers going in the field in developing regions,” he says. “We think it could be very useful for the military, when you’re going out on a mission in the field, or for hikers and athletes going for long hauls. You could even have it in the back of your car as an expanded first aid kit.”

These pellets could also be incorporated into educational tools — “the biotech equivalent of a chemistry kit,” Collins says. “You could envision using these pellets to allow students to conduct synthetic biology experiments at home, or in middle schools and high schools.”

Another application Collins plans to pursue is integrating the pellets into “smart bandages” that would detect an infection and then begin producing the appropriate antimicrobial peptide to treat the infection.

The research was funded by the Wyss Institute; the Ragon Institute of MGH, MIT, and Harvard; the Paul G. Allen Frontiers Group; and the Defense Threat Reduction Agency.

Related News

-

News A Day in the Life of a Start-Up Founder and CEO

At CPHI we work to support Start-Up companies in the pharmaceutical industry and recognise the expertise and innovative angles they bring to the field. Through our Start-Up Programme we have gotten to know some of these leaders, and in this Day in the ... -

News Biopharmaceutical manufacturing boost part of new UK government budget

In their national budget announced by the UK Labour Party, biopharmaceutical production and manufacturing are set to receive a significant boost in capital grants through the Life Sciences Innovative Manufacturing Fund (LSIMF). -

News CPHI Podcast Series: The power of proteins in antibody drug development

In the latest episode of the CPHI Podcast Series, Lucy Chard is joined by Thomas Cornell from Abzena to discuss protein engineering for drug design and development. -

News Amgen sues Samsung biologics unit over biosimilar for bone disease

Samsung Bioepis, the biologics unit of Samsung, has been issued a lawsuit brought forth by Amgen over proposed biosimilars of Amgen’s bone drugs Prolia and Xgeva. -

News CPHI Podcast Series: Why we need to consider women in clinical trials

The latest episode of the CPHI Podcast Series with Lucy Chard covers women's health, specifically women's representation in clinical trials, the associated bias, and the impacts on health for this population. -

News US FDA does not approve MDMA therapy for PTSD, requests more data

The MDMA-based therapeutic developed by Lykos Therapeutics, a California-based Public Benefit Corporation (PBC), has been reviewed and unapproved by the US FDA. The regulator has requested additional phase III trial data for further safety and efficacy... -

News Novartis and Viatris latest facing lawsuit over HeLa cell misuse

Global pharmaceutical companies Novartis and Viatris are the latest hit with a lawsuit claim pertaining to alleged misuse of the ‘HeLa’ cell line from the estate of woman whose cancerous tissue cells were taken without consent. -

News Sanofi invests billions into Frankfurt insulin production site

French pharmaceutical company Sanofi have announced an investment of EUR1.3 billion at their existing BioCampus site in Frankfurt am Main for the expansion of insulin production.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)

.png)

.png)

.png)