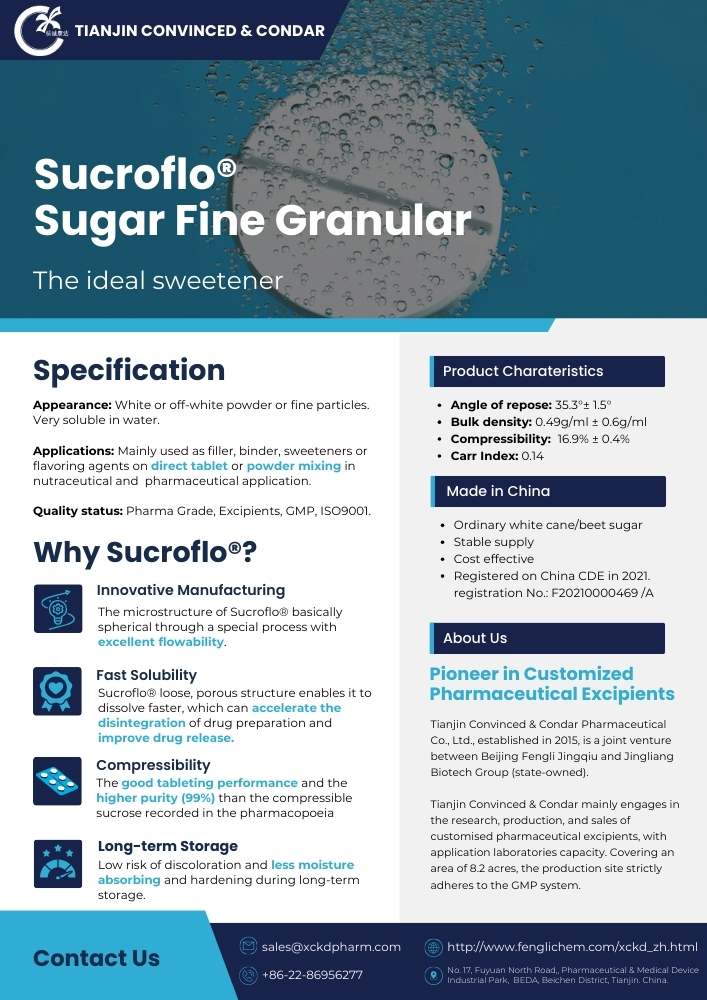

Sucroflo®~ an option for compressible sugar fine granular with good flowing ability

Sucroflo® introduction

Sucrose is a typical

sweetener and a benchmark for sweetness assessment. Sucrose is widely used in

food, medicine, and health products. In the pharmaceutical industry, it can be

used as a nutritional

sweetener, excipient, filler, adhesive, diluent, pore-forming agent, pellet

core, freeze-drying protective agent, etc.

Under the growing

demand from the market, we have developed a special pharma-grade sucrose with

fast-dissolving properties that can be used for the direct compression of tablets. Such as Vitamin

C effervescent tablets.

The microstructure

of Sucroflo ® Sugar Fine Granular is

basically spherical. This property improves the fluidity,

speeds up the dissolution rate, and solves the problems of large particle size

of Sucrose and difficult tablet pressing.

Sucroflo® is a fast-dissolving pharma-grade sugar fine granular for direct compression tabletting with minimal risk of discoloration and is not prone to hygroscopicity and hardening during long-term storage.

Feature 1: Originated from European technology, creating superior tabletting performance

Sucroflo® is developed by Tianjin Convinced & Condar Pharmaceutical Co., Ltd. and a European research centre. It has been trial and pilot-tested multiple times in Ireland, the UK and China. The R&D process lasted two and a half years. Its excellent physical indicators enhance the tabletting quality of the preparation.

Feature 2: Instant dissolution

Sucrose is highly soluble in water (1 ml of water can dissolve about 2 g of sucrose at room temperature), but its dissolution speed is not fast.

The production process of Sucroflo® Sugar Fine Granular transforms sucrose from crystals to an amorphous state, so that each small particle forms a loose structure with more pores, thereby greatly improving the dissolution speed.

Feature 3: Extremely low risk of discolouration

Have you noticed the white sugar at home will slowly turn yellow after being left for a long time? This is usually caused by the sulfite method used in sucrose production; this production process is relatively low in cost, but the impurity content is relatively high. The sucrose produced by this process has a risk of discoloration during the drug production process - especially common on sugar-coated tablets. To eliminate the risk, we thoroughly screen the manufacturers of starting materials, select high-quality raw materials, and customize special processes to ensure that the end product has better storage stability.

Feature 4: Less moisture absorbing and hardening during long-term storage

Sucroflo® Sugar Fine Granular contains very low moisture, and the anti-hygroscopic inner and outer packaging design makes our products able to keep out moisture and clumping during long-term storage. It perfectly meets the needs of high-end customers for product stability.

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance