STERILE SOLUTION MANUFACTURING VESSEL

Product Description

Sterinox Systems

-

IN

-

2017On CPHI since

-

25 - 49Employees

Company types

Primary activities

Categories

Specifications

Sterinox Systems

-

IN

-

2017On CPHI since

-

25 - 49Employees

Company types

Primary activities

More Products from Sterinox Systems (7)

-

Product Multi Column Distillation Plant ( WFI Generation Plant)

Multi Column Distillation plant ( Water for Injection Generation Plant) produces low conductivity pyrogen / endotoxin free Water For Injection (WFI) by stage distillation process. Our Plant is based on falling Film Evaporator Technology. • Capacity varies from 5 to 6,000 litres per hour • Desig... -

Product Pure Steam Generator

The Pure Steam Generator is used to produce Pyrogen/ Endotoxin free Sterile Steam. The Pure Steam Generator (PSG) utilizes a falling-film type evaporator which produces pyrogen free pure steam, using a unique separation technology. Feed water is continuously pumped to the top of the evaporator heat exc... -

Product PW Distribution SKID

• PW and WFI Storage Tanks are manufactured as per cGMP guideline s & ASME VIII, DIV 1 • standard Storage tanks can be plain, jacketed or limpet type, provided by suitable rockwool/glasswool insulation and AISI 304 stainles ssteel cladding. • If required, provision of elec... -

Product Point of Use Heat Exchanger (POU HE)

Our extensive engineering expertise, unique designs and manufacturing techniques provide the most compact heat exchangers offering high heat transfer area, low utility consumptions for thermal exchange application and quick delivery of the product.

Our POU HE (Point of Use Heat Exchanger)... -

Product CIP and SIP System

Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) are systems designed for automatic cleaning and disinfecting without major disassembly and assembly work. We design, develop, manufacture, supply and install Mobile and Fixed CIP & SIP Units for sanitization and sterilization. The units are custo... -

Product Liquid Oral Manufacturing Plant ( Syrup Manufacturing Plant)

Oral liquid manufacturing plant comprises of sugar syrup vessel, online sugar syrup pre-filter, manufacturing vessel storage vessel, vacuum system for transfer of sugar and sugar syrup, product piping, control panels and transfer pumps. The construction of the complete system is done in a way tha... -

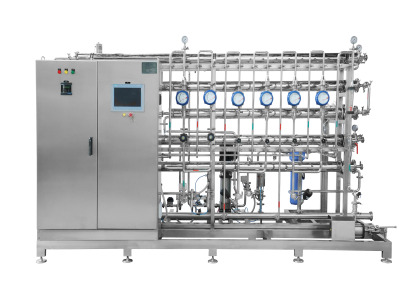

Product Purified Water (PW) Treatment Plants (RO-EDI Plants)

Purified Water (PW) Treatment Plants (RO-EDI Plants) generates High Purity water for pharmaceutical, Biotech, Semiconductor and ‘Food & Beverages Industry.

Sterinox Purified Water Treatment plants are designed and optimised for hassle free low maintenance operation. The entire syste...

Sterinox Systems resources (1)

-

Brochure Sterinox Brochure

We introduce our company M/s Sterinox Systems as one of the leading pharmaceutical machinery manufacturers in India. We are a technology driven quality conscious engineering organization.

We are into the designing & manufacturing of pharmaceutical machineries. We have a range of machineries and equipments for injectable, liquid & ointment sections. Given below is a list of machines, equipments / Plants being manufactured by us.

Also Please find attached our company brochure for furthermore information on our products.

By implementing benchmarking technologies in manufacturing process and setting up fully-equipped in house quality, we are committed to international standards, We at Sterinox, ensure the high Quality products for our customers. We manufacture as per cGMP (current Good Manufacturing Practice) and adhere to our quality standards stringently. We have a QAP (Qua...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance