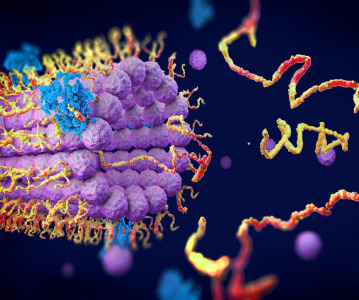

Process uses 3-D Printing to Produce Tough but Flexible Hydrogel Structures

Researchers have developed a new way of making tough — but soft and wet — biocompatible materials, called “hydrogels,” into complex and intricately patterned shapes. The process might lead to injectable materials for delivering drugs or cells into the body; scaffolds for regenerating load-bearing tissues; or tough but flexible actuators for future robots, the researchers say.

The new process is described in a paper in the journal Advanced Materials, co-authored by MIT associate professor of mechanical engineering Xuanhe Zhao and colleagues at MIT, Duke University, and Columbia University.

Zhao says the new process can produce complex hydrogel structures that are “extremely tough and robust,” and compatible with the encapsulation of cells in the structures. That could make it possible to 3D-print complex hydrogel structures; for example, implants to be infused with cells and drugs and then placed in the body.

Hydrogels, defined by water molecules encased in rubbery polymer networks that provide shape and structure, are similar to natural tissues such as cartilage, which is used by the body as a natural shock absorber. The new 3-D printing process could eventually make it possible to produce tough hydrogel structures artificially for repair or replacement of load-bearing tissues, such as cartilage.

While synthetic hydrogels are commonly weak or brittle, a number of them that are tough and stretchable have been developed over the last decade. However, previous ways of making tough hydrogels have usually involved “harsh chemical environments” that would kill living cells encapsulated in them, Zhao says.

The new materials are benign enough to synthesize together with living cells — such as stem cells — which could then allow high viability of the cells, says Zhao, who holds a joint appointment in MIT’s Department of Civil and Environmental Engineering.

In addition, the previous work was not able to produce complex 3-D structures with tough hydrogels, Zhao says. The new biocompatible tough hydrogel can be printed into diverse 3-D structures such as a hollow cube, hemisphere, pyramid, twisted bundle, multilayer mesh, or physiologically relevant shapes, such as a human nose or ear.

The new method uses a commercially available 3D-printing mechanism, Zhao explains. “The innovation is really about the material — a new ink for 3-D printing of biocompatible tough hydrogel,” he says — specifically, a composite of two different biopolymers. “Each [material] individually is very weak and brittle, but once you put them together, it becomes very tough and strong. It’s like steel-reinforced concrete.”

One of the two polymers provides elasticity to the printed material, while the other allows it to dissipate energy under deformation without breaking. A third ingredient, a biocompatible “nanoclay,” makes it possible to fine-tune the viscosity of the material, improving the ability to control its flow through the 3D-printing nozzle.

The material can be made so flexible that a printed shape, such as a pyramid, can be compressed by 99%, and then spring back to its original shape, Sungmin Hong, a lead author of the paper and a former postdoc in Zhao’s group, says; it can also be stretched to five times its original size. Such resilience is a key feature of natural bodily tissues that need to withstand a variety of forces and impacts.

Such materials might eventually be used to custom-print shapes for the replacement of cartilaginous tissues in ears, noses, or load-bearing joints, Zhao says. Lab tests have already shown that the material is even tougher than natural cartilage.

The next step in the research will be to improve the resolution of the printer, which is currently limited to details about 500 micrometers in size, and to test the printed hydrogel structures in animal models. “We are enhancing the resolution,” Zhao says, “to be able to print more accurate structures for applications.”

In addition to biomedical applications, the same technique could be applied to printing a variety of soft but tough structural materials, he says, such as actuators for soft robotic systems.

Related News

-

News A Day in the Life of a Start-Up Founder and CEO

At CPHI we work to support Start-Up companies in the pharmaceutical industry and recognise the expertise and innovative angles they bring to the field. Through our Start-Up Programme we have gotten to know some of these leaders, and in this Day in the ... -

News Biopharmaceutical manufacturing boost part of new UK government budget

In their national budget announced by the UK Labour Party, biopharmaceutical production and manufacturing are set to receive a significant boost in capital grants through the Life Sciences Innovative Manufacturing Fund (LSIMF). -

News CPHI Podcast Series: The power of proteins in antibody drug development

In the latest episode of the CPHI Podcast Series, Lucy Chard is joined by Thomas Cornell from Abzena to discuss protein engineering for drug design and development. -

News Amgen sues Samsung biologics unit over biosimilar for bone disease

Samsung Bioepis, the biologics unit of Samsung, has been issued a lawsuit brought forth by Amgen over proposed biosimilars of Amgen’s bone drugs Prolia and Xgeva. -

News CPHI Podcast Series: Why we need to consider women in clinical trials

The latest episode of the CPHI Podcast Series with Lucy Chard covers women's health, specifically women's representation in clinical trials, the associated bias, and the impacts on health for this population. -

News US FDA does not approve MDMA therapy for PTSD, requests more data

The MDMA-based therapeutic developed by Lykos Therapeutics, a California-based Public Benefit Corporation (PBC), has been reviewed and unapproved by the US FDA. The regulator has requested additional phase III trial data for further safety and efficacy... -

News Novartis and Viatris latest facing lawsuit over HeLa cell misuse

Global pharmaceutical companies Novartis and Viatris are the latest hit with a lawsuit claim pertaining to alleged misuse of the ‘HeLa’ cell line from the estate of woman whose cancerous tissue cells were taken without consent. -

News Sanofi invests billions into Frankfurt insulin production site

French pharmaceutical company Sanofi have announced an investment of EUR1.3 billion at their existing BioCampus site in Frankfurt am Main for the expansion of insulin production.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)

.png)

.png)

.png)