Pharmaceutical packagers scaling up to meet potential COVID-19 vaccine demand

Amid concerns that global immunization programs may suffer from a shortage of vials to hold doses of approved vaccines against COVID-19, pharmaceutical packagers are busy ensuring they have the required capacity to meet the huge demand.

As the world waits to see which anti-COVID 19 vaccines will be first to gain regulatory approval and come to market, pharmaceutical packagers are busy scaling up their vial manufacturing capacity to ensure the challenging demand situation will be met.

According to Italy’s Stevanato Group, worldwide demand will increase over the next two years by an estimated 1 billion to 2 billion of new glass vials that are able to contain multiple vaccine doses.

Some experts have questioned whether delivery of successful vaccines to the global population may be hampered by a potential shortage of vials needed to hold the vital shots.

In June, German pharma glass manufacturer SCHOTT announced that it had signed supply agreements for vials to package up to 2 billion vaccine doses with pharmaceutical companies including partners of ‘Operation Warp Speed,’ the US government initiative to serve local vaccine production needs.

The agreements came into effect in July with first vials already being delivered to companies in Asia, North America and Europe.

SCHOTT, the world’s largest supplier of borosilicate glass for medical bottles and syringes, said it has the infrastructure in place to expand vial production capacity at many of its sites, including the US and Germany, by another 1 billion vaccine doses and that it is currently in discussions with respective state officials over the best possible production location.

In India, SCHOTT’s 50-50 joint venture, SCHOTT KAISHA is supplying COVID-19 vaccine vials to Serum Institute of India and other companies developing vaccines.

The joint venture operates four Indian manufacturing facilities in Jambusar and Umarsadi in Gujarat, Daman, and Baddi in Himachal Pradesh. It also produces the pharmaceutical glass tubing for the packaging itself at its global sites including one in Jambusar in Gujarat.

“SCHOTT KAISHA has been known to scale up extremely fast in order to meet customer demands over the past decade, which is also evident from its two new facilities in Umarsadi and Baddi,” said Rishad Dadachanji, director at SCHOTT KAISHA, adding that due to its robust supply chain and support from SCHOTT’s global sites, the company is confident it can quickly expand its production capabilities in case of further demand.

Dadachanji added that another key advantage is that many pharma companies have been processing the company’s vials on their fill and finish lines for many years: “Hence, no time-consuming adaptations of fill and finish equipment will slow down vaccine distribution.”

SiO2 Materials Science is another packaging specialist which has signed a large supply agreement; in June it announced a USD 143 million deal with the US Department of Defense’s Joint Program Executive Office for Chemical, Biological, Radiological, and Nuclear Defense (JPEO-CBRND) in partnership with the Biomedical Advanced Research and Development Authority (BARDA) to accelerates production scale-up of its primary packaging platform for storing novel coronavirus (SARS-CoV-2) vaccines and therapeutics.

The company said it has successfully scaled its hybrid vial manufacturing capacity ahead of schedule to 400 million doses and is on track to hit 1.2 billion capacity before the end of 2020.

SiO2’s patented materials science is a combination of a plastic container with a microscopic, thin, undetectable to the naked eye, pure glass coating for biological drugs and vaccines.

“The nation can produce all the vaccines we want, but we must have appropriate containers to store them and deliver them to patients safely,” said Dr. Robert Langer, institute professor at Massachusetts Institute of Technology and advisor to SiO2. “Many drug development and drug formulation innovations can be limited due to variables associated with traditional glass vials and syringes. The SiO2 vials and syringes eliminate these variables and allow drug development partners to bring their innovations to life.”

Related News

-

News CPHI Milan post-show panel: Importance of advocacy projects in business

In the Packaging Innovation Theatre from CPHI Milan this year, sponsored by the Alliance of the RTU, we held a panel on: ‘Elevating Brand Perception: Integrating Advocacy Projects into Business Strategies’. The session aimed to explore how ... -

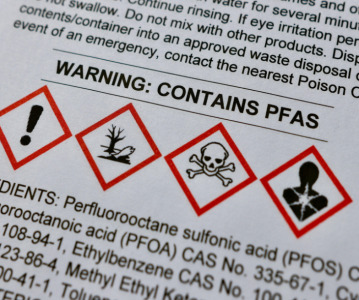

News How are new PFAS regulations impacting excipient manufacture? – CPHI North America Interview

In another interview from CPHI North America in Philadelphia in May, Peter Schmitt from Montesino Associates talks about his presentation on 'Navigating the Waters of Change: The Impact of New PFAS Regulations on the Manufacture of Excipients ... -

News CPHI Online Webinar Series – Optimising Pharma Manufacturing through Digital Transformations

This month’s CPHI Webinar Series explored achieving manufacturing excellence in pharma through the digitalisation of daily processes. Presented by Joe Doyle, Head of Sales at EviView, and Bikash Chatterjee, President and Chief Scientific Off... -

News CPHI Online Webinar Series – Innovative Strategies for B2B Pharma Marketeers

On February 20, 2024, CPHI Online hosted a webinar on Innovative Strategies for B2B Pharma Marketeers. Featuring expert speakers from across the pharmaceutical value chain, this webinar delves into how B2B pharma marketeers can create better content to... -

News CPHI Barcelona Speaker Interview: Rare diseases and the microbiome boom

At CPHI Barcelona (24–26 October, 2023) we took the time to catch up with one of our speakers, Rajiv Khatau who gave a presentation on: The Microbiome Boom - Unlocking Potential Through Listening to the Gut and was a panellist on:&... -

News CPHI Barcelona 2023 – the Product Innovation sessions: tired of leaking softgels?

Learn how to improve softgel seams and process efficacy from GELITA's presentation in the Product Innovation theatre from the Content hall at CPHI Barcelona in October 2023. -

News How to Commercialise an Advanced Therapy: Connect to Frankfurt on-demand

In this Connect to Frankfurt session, Andrea Zobel, Senior Director, Personalized Supply Chain at World Courier (Berlin Germany), Melissa Lattanzi, VP Emerging Therapies at AmerisourceBergen (King of Prussia, USA), and Hans-Peter Scherzer, Customer Suc... -

Sponsored Content CPHI Podcast Series: Key Considerations in Selecting the Right CMO Partner

In this month's episode we hear from Jayna Blake, Senior Project Manager for Technical Programs at Baxter BioPharma Solutions, on key considerations for successful CMO selection.

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)

.png)