Multi-inspection Platforms

Product Description

Wilco AG

-

CH

-

2017On CPHI since

-

4Certificates

-

100 - 249Employees

Company types

Primary activities

Categories

Specifications

Wilco AG

-

CH

-

2017On CPHI since

-

4Certificates

-

100 - 249Employees

Company types

Primary activities

More Products from Wilco AG (5)

-

Product Automated NIR Spectroscopy

The SPECTRA NIV is a high speed inspection platform for the non-destructive acquisition and analysis of NIR spectra of lyophilized products. NIR spectroscopy allows the determination of multiple parameters simultaneously such as moisture concentration, defects of the lyophilizate and the identification of ... -

Product Automated Leak Testing for Sterile Pharmaceuticals

Our automated CCI testers for vials, syringes, ampoules, blow-fill-seal containers, IV bags and other pharmaceutical packaging use the latest generation of differential pressure testing or headspace analysis procedures allowing a highly sensitive and robust measurement.

Highlights: • Indus... -

Product Automated Visual Inspection

The automated visual inspection platform VISION CAV is designed for a customized, fully-automated inspection of particles and cosmetic defects of vials with liquid or lyophilized products.

Cosmetic and particle inspectionFor the inspection of cosmetic defects, the test samples ar... -

Product Container Closure Integrity Tester for laboratory use

With our wide range of lab testing equipment we provide solutions for the early stages in the development processes as well as for quality control in commercial manufacturing. Being able to transfer the test method from R&D to production reduces risks and saves time.

The NEO series combines high... -

Product Automated Headspace Analysis

The verification of quality relevant attributes of the headspace conditions e.g. in lyophilized and liquid filled vials, requires non-destructive and robust inspection technologies. The SPECTRA HSX platform is designed to meet the highest requirements in terms of sensitivity and throughput for automated He...

Wilco AG resources (4)

-

News NEW dual laser Headspace Analyzer NEO HSX DUO

Swiss specialist machine builder, WILCO AG, is launching another laboratory inspection system within the NEO series. The NEO HSX DUO Headspace Analysis Laboratory System is designed for various inspection tasks related to integrity testing, as well as process control of pharmaceutical primary packaging materials and product types. The NEO HSX DUO is the world's first Headspace Analyzer with two different laser heads. These enable simultaneous measurement of O2 and CO2 gases, saving space, time and budget in the lab. -

Video WILCO AG - Introduction CCIT & Visual Inspection Solutions - Being sure.

Together we will find a leak testing (CCIT) and visual inspection solution to optimally inspect your products. With our experience, broad technology portfolio, robust mechanical engineering and service portfolio over the entire product life cycle we provide maximum security. -

Whitepaper Inspection of vials with lyophilzates - Application

Lyophilized vials are inspected with three inspection technologies on one machine. The combination of visual inspection, headspace analysis and NIR spectroscopy ensures 100% integrity testing of the vials as well as testing of the lyo cake. -

Datasheet Custom-designed particle inspection for automated visual inspection systems

Parenteral drug products are required to be 100% visually inspected. As each product and its packaging define their specific inspection task, standardized inspection setups may lead to a high level of false rejects and underperforming inspection results. In contrast, a customized solution provides the opportunity to improve the inspection by reducing false rejects and increasing the detection rates.

Learn more: https://www.wilco.com/technologies/visual-inspection/

Frequently Viewed Together

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

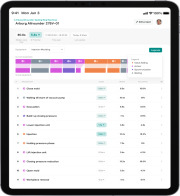

An easy-to-use platform with a detailed dashboard showing your leads and performance

-comp296617.jpeg)