For the perfect cleaning of large items as bins, drums, tanks, IBC, IBC...

From 4,25 to 10,5 cubic meters (from 150 to 370 cu.ft) chamber volume, customizing loading racks to customer needs, LB Series is a system specifically designed for the cleaning and drying of containers and drums in pharmaceutical validated processes.

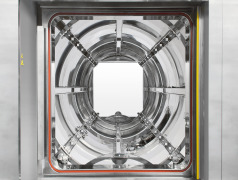

Custom made for individual customer needs, these units feature the

possibility to rotate both the container being cleaned and/or the spray

nozzle arm 360° inside the object ensuring exceptional cleaning of all

surfaces of the container.

√ Highest cleaning performance

√ Easy cart connections

√ 360° continuous bin rotating during operation

√ Drying unit with 1000 m3/hour capacity

√ Repeatable and validatable

Inspection, testing, documentation and training

We

believe on the importance to show and to demonstrate that all the steps

of the manufacturing processes, starting from the specifications and

the component selection up to the assembly and factory testing are made

in accordance with the customer specifications and performance

requirements. ICOS PHARMA can furthermore demonstrate and document that

our quality control program strictly follows the Good Engineering

Practice. ICOS PHARMA follows the ISPE's GAMP guidelines to respect the

project execution and the supplying of the documentation to support the

customer's qualifications.

Comprehensive validation support documentation

» To

ensure compliance with specifications and documentation is maintained,

in-process checking is performed during the manufacturing process.

» A

FAT (Factory Acceptance Test) is made on each unit and a complete set

of documentation is supplied to the customer together with installation,

user and instruction manual when the machine is delivered.

» On

request Pre-Qualification of the system can be supplied: this will

carry out the same test procedures as defined in the IQ-OQ protocols to

be later performed on site as part of the validation process. This

procedure will help the start up of the machine pointing out any minor

issue with the equipment and the documentation and precede the site

acceptance testing which will be performed later on.