- Home

- Nuova Guseo

- Jet Mill

CPHI Online is the largest global marketplace in the pharma ingredients industry

-

Products0

-

Companies0

-

Articles0

-

Events0

-

Webinars0

Jet Mill

Product Description

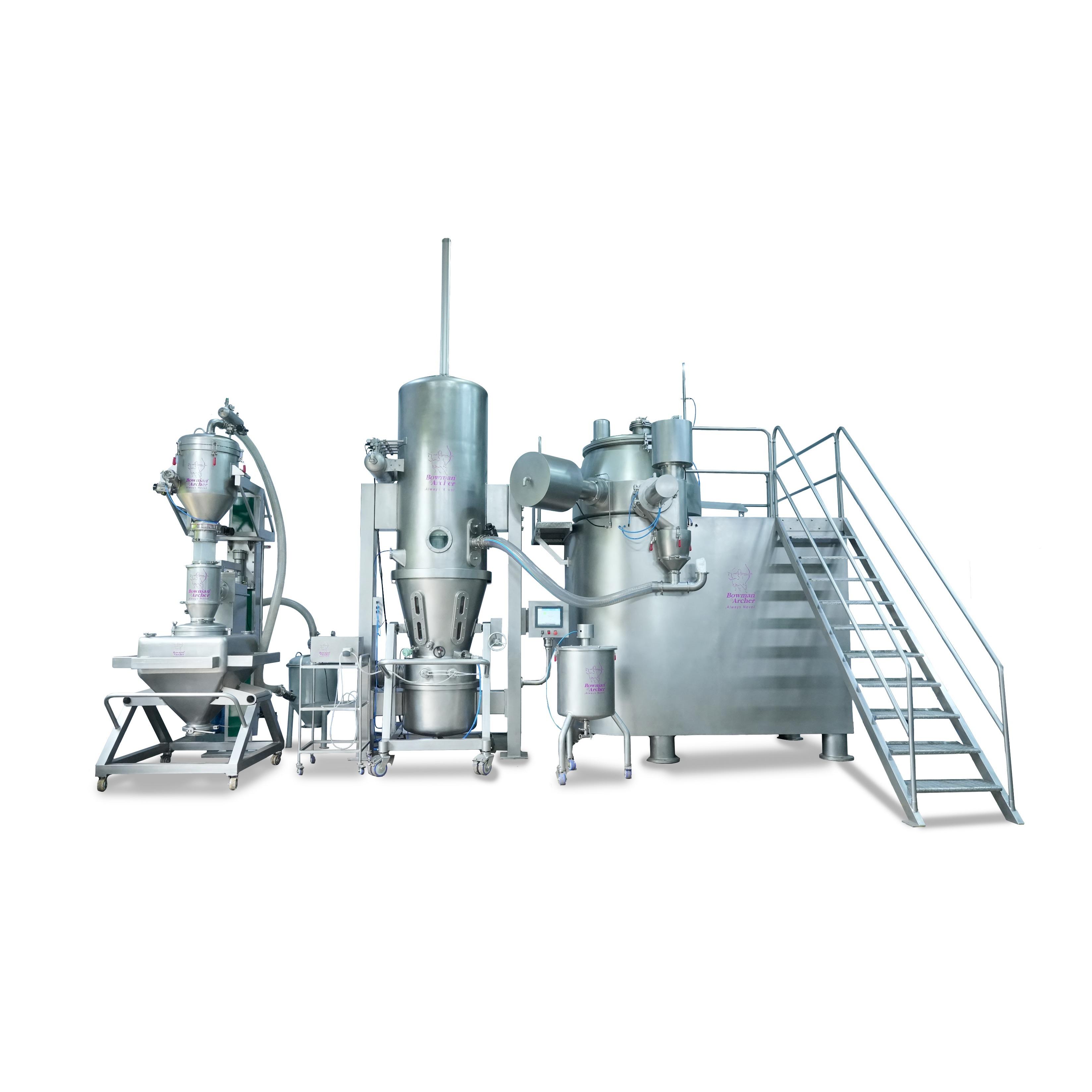

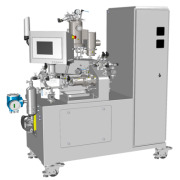

Designed to achieve particularly high fineness, this mill offers the possibility to obtain particle sizes even below 5 microns. The working principle does not contemplate the use of grinding bodies, since the reduction takes place exclusively by collision between the particles of product, fed in the grinding chamber through a Venturi injector. The particles are quickly accelerated by a stream of gas (compressed air, nitrogen, argon, or steam) injected by means of nozzles placed at the periphery. These are dragged in a vortical movement that causes them to collide repeatedly, progressively reducing the diameter and mass as long as the energy accumulated by the same drops to negligible values. Micronized particles are carried by the exhausted air into a suitable cyclone filter. At the inner of the cyclone-filter the air is dedusted through a set of filtering bags, in special fabric, and discharged to the outside, while the micronized product is retained on the outer surface of the same. The shaking of the filtering bags is carried out by means of a timed reverse jets of compressed air, which allows the removal of the micronized product that is collected in the bottom hopper of the cyclone-filter, allowing an optimal performance in terms of product recovery. Of simple construction, Micronette series mills are easy to be disassembled without the aid of mechanical tools, to facilitate the cleaning operations and of equally simple use, so that it doesn’t require the intervention of specialized personnel.The stainless steel version with sanitary type finishes is particularly suitable for the treatment of pharmaceutical products. Furthermore, where necessary, the system can operate in a closed inert cycle (generally with N2) with almost total gas recovery. Integrated configurations within insulator are also available when it is necessary to process highly active products, in addition to systems specially designed for R&D, able to micronize very small batches of product. Of particular interest is the configuration of the cyclone filter fitted with a device for 90° rotation of the filter, which ensures an easy access to the inside of the device in order to facilitate the extraction of the sleeves and the subsequent clean-up of the cone, avoiding the use of ramps or elevators. For particularly active products, sleeves can be extracted through an accessory (supplied separately) consisting of a sight glass provided with gloves, to be installed on top of the filter, ensuring a lower exposure of the operator to dust.

Nuova Guseo

-

IT

-

2020On CPHI since

-

-

-

Via Dante 4, 43011, Villanova Sull'Arda, (PC), Italy

Categories

Nuova Guseo

-

IT

-

2020On CPHI since

-

-

-

Via Dante 4, 43011, Villanova Sull'Arda, (PC), Italy

More Products from Nuova Guseo (1)

-

Product Glove Box Isolator

If the isolation technology in recent years is playing a role of growing importance, this is mainly due to the well-established trend, especially in the chemical and pharmaceutical field, to treat substance and / or develop molecules with high activity and toxicity (API – HAPI). This in conj...

Nuova Guseo resources (1)

Recommended Products

-

Product Compounding Aseptic Containment Isolator for Dispensing

KEY FEATURES AND BENEFITS:

Optimized Material Handling:

- Airlock Introduction: Efficiently introduce materials into the airlock, minimizing contamination risks and ensuring a smooth workflow.

- ...

-

Product Dispax Reactor DR

three-stage high shear inline dispersing machine used for the production of very fine emulsions and suspensions. It can be used (amongst others) for API wet milling and emulsification of pharmaceutical emulsions.

-

Product SCM

Suture crimping machine

A wide range of needles and threads can be handled and a fast product changeover time provides the flexibility of producing large or small batches.

Each suture is subjected to a pull test to guarantee a constant high-quality thread-needle combinatio...

-

Product HPAPIs ISOLATOR

• Wide working chamber with a sloping front wall that can be opened upwards• Prismatic Air Lock

• Static sealsCentrifugal exhauster with inverter

• Hepa (H14) input filtering unit

• Double Hepa (H14) output filtering unit

• Filtered safety valve

• Pressure gauges

• Pressure transm...

-

Product Automatic & Semiautomatic R&D Reactor, Condenser, Receiver with Heating ...

1. Automated Efficiency: Our Automatic R&D Reactor System streamlines operations, allowing for precise control and automation of crucial parameters, ensuring reproducibility in experiments.

2. Semiautomatic Flexibility: For those seekin...

-

Product Flow Miniplant

Bench-top pilot plant for development and small-scale production. The Flow Miniplant is Microinnova’s bench-top flow pilot-plant for the production of quantities between 1 and 100 litres per hour. It bridges the gap between lab-scale flow process development and bulk manufacturing. It’s an indispensable st...

-

Product Hanningfield Mills & Sifters

Gansons, in partnership with Hanningfield - UK provides high integrity machines for achieving various particle sizing processes; handling everything from bulk agglomerates to micronized material.

-

Product GEA Pharma & Healthcare

The Flexibility You Want. The Quality You Need.

Equipped with a wealth of product, customer and market knowledge, you can rely on GEA to deliver end-to-end support for your pharmaceutical manufacturing project. Whether it’s a flexible continuous processing line for an over-the-counter pill, a fully ...

-

Product MC DecJet® Spiral Jet Mills

The new 4th generation MC DecJet® systems stand for: • Narrow Particle Size Distribution (PSD)

• Simple and rapid assembly/disassembly • Limited number of components • High yields • Low energy consumption • Sterile manufacturing • PSD scalability with all MC DecJet® models

-

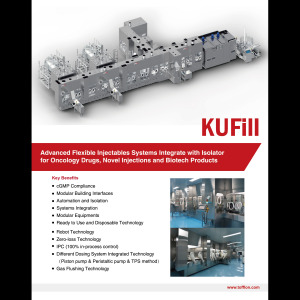

Product KUFill System

Shanghai tofflon science & technology co. Ltd offers a wide range of filling lines which includes ampoule filling line. Features: it is integrated with washing machine, sterilizing tunnel, filling and sealing machine, it reduces any potential contamination risk from human operation. Contcat us for more...

-

Product AURUS Cone Mill

Conical Milling Machine known world over for its proven track record at size reduction, sieving and deagglomeration of powders & granules.

It is an essential tool in a range of processes such as fine-grinding, uniform size reduction, dispersion, sieving and wet as well as dry milling.

... -

Product VIP Laser Drill + NIR - Tablet Drilling Machine

A pharmaceutical industry first, the VIP Laser Drill + NIR incorporates optional near-infrared spectroscopy alongside precision CO2 laser drilling and vision inspection for the production of osmotic drugs.

This versatile machine uses NIR inspection to verify a tablet’s enteric coating prior to l...

-

Product REACTOR SYSTEMS BASED ON GLASS-LINED REACTORS WITH JACKET AND GLASS AUXI...

• Operating volume of the glass-lined reactor: from 50 to 5000 l • Volume of glass measuring vessels with a jacket and an agitator from 15 to 100 l • Volume of glass measuring vessels without a jacket from 10 to 300 l • Mounting of glass components on a stainless-steel scaffolding. • Scaffolding...

-

Product MIXER / DISSOLVER

Our line of stainless steel mixer/dissolvers is suitable for all pharmaceutical application fields, the systems are fully customizable according to user needs.

There are many combinations, mixing, dissolution and thermoregulation of the product, liquid analysis, weighing and dosing us...

-

Product LT 20 - Automation within a small footprint

The LT 20 allows you to produce automatically without requiring a large footprint. From small series to a medium-high output, you can always work in the production environment that suits you best.

+ Small footprint

+ ISO 8 compatible, GMP

+ Various cleanability levels

+ Zero to medium pro... -

Product Fluid Bed Dryer

Sefar Filter Solutions for Fluid Bed DryerFluidized bed technology is used in many applications such as the formulation process in the pharmaceutical industry or the production of fine chemical powders by mixing, agglomeration, granulation, sizing, drying, coating or micronizing.

Over the last 2...

-

Product Rommelag SERVICE

Rommelag offers the system configuration tailored to the product, supports you with the in-house pharmaceutical service already during the planning phase and provides classic after-sales service from installation of the system by our own technicians to maintenance, repair and complex modifications and ...

-

Product Complete Injectable Ampoule Packaging Line

Ampoule Packaging Line - For Packaging 1 Ml To 20 Ml AmpoulesComplete Injectable Ampoule Line is the perfect solution for the pharmaceutical industry. HMPL's state-of-the-art Ampoule Filling Line packaging from 1 ml to 20 ml ampoules with up to 400 ampoules per minute output speed. The Ampoule Filling Line...

-

Product STEP T420 Tablet press

APPLICATION

Level 3 safety circuit, safe operation

High precision manufacturing, reliable operation

Modular design for quickly installing and disassembling

High Performance PLC and Industrial computer control

Servo motor adjusts pressure and filling de...

-

Product Complete lines for sachet and stick-packs in cartons

Universal Pack Synthesis complete automatic packaging Lines are individually custom-built, whether for primary or secondary packaging, guaranteeing the highest efficiency together with the most compact machine layout, perfectly in line with Universal Pack traditional concepts.

-

Product Filling Line Isolator

Filling lines enclosed in an isolation technology are now widely utilized for the aseptic manufacture of sterile pharmaceuticals in various container formats.

Esco Pharma’s filing line isolator provides an ISO Class 5 / Grade A environment, ensuring the sterility of the work zone for the most de...

-

Product DYNO®-MILL

GRINDING & DISPERSION TECHNOLOGY

Wet grinding technology focuses on the controlled real size reduction, dispersion and deagglomeration of solid particles in a liquid medium. Particle finenesses in the micro to nanometer range can be achieved. For more than 60 years, WAB-GROUP&n...

-

Product prefilled syringe

the prefilled syringe is produced by All-European machine, such as Ambeg, BAUSCH+STROBEL, and OCMI. our annual production capacity is more than 5 millon pcs a year. the prefilled syringe is packed in nest&tub, then sterilized by the Ethylene oxide sterilization

-

Product Laser Printing Inspection Machine

PLANET LPI, UV laser printing and complete vision inspection was developed based on our cumulated technologies and accurate positioning as per shape tracing, which draws the innovative result and eliminating lots of traditional troubles such as distortion of print, out of position, and etc.

qq...

-

Product MINI-POLYGRAN®

The Polygran series of Roller Compactors brings the science of roller compaction to the nutraceutical, food, and chemical industries. Redesigned HMI & Control systems improve batch protocols and export functionality to satisfy 21 CFR Pt 11 requirements. R&D and Small-Scale Manufacturing. OEL...

-

Product JTFZ Series Lifting Tipper With Mill

JTFZ Series Lifting Tipper with on-line dry cone mill is used for unloading and transferring the dried or granulated products from material bowl of fluid-bed granulator,and after dry milling then to blender bin or sieving.

-

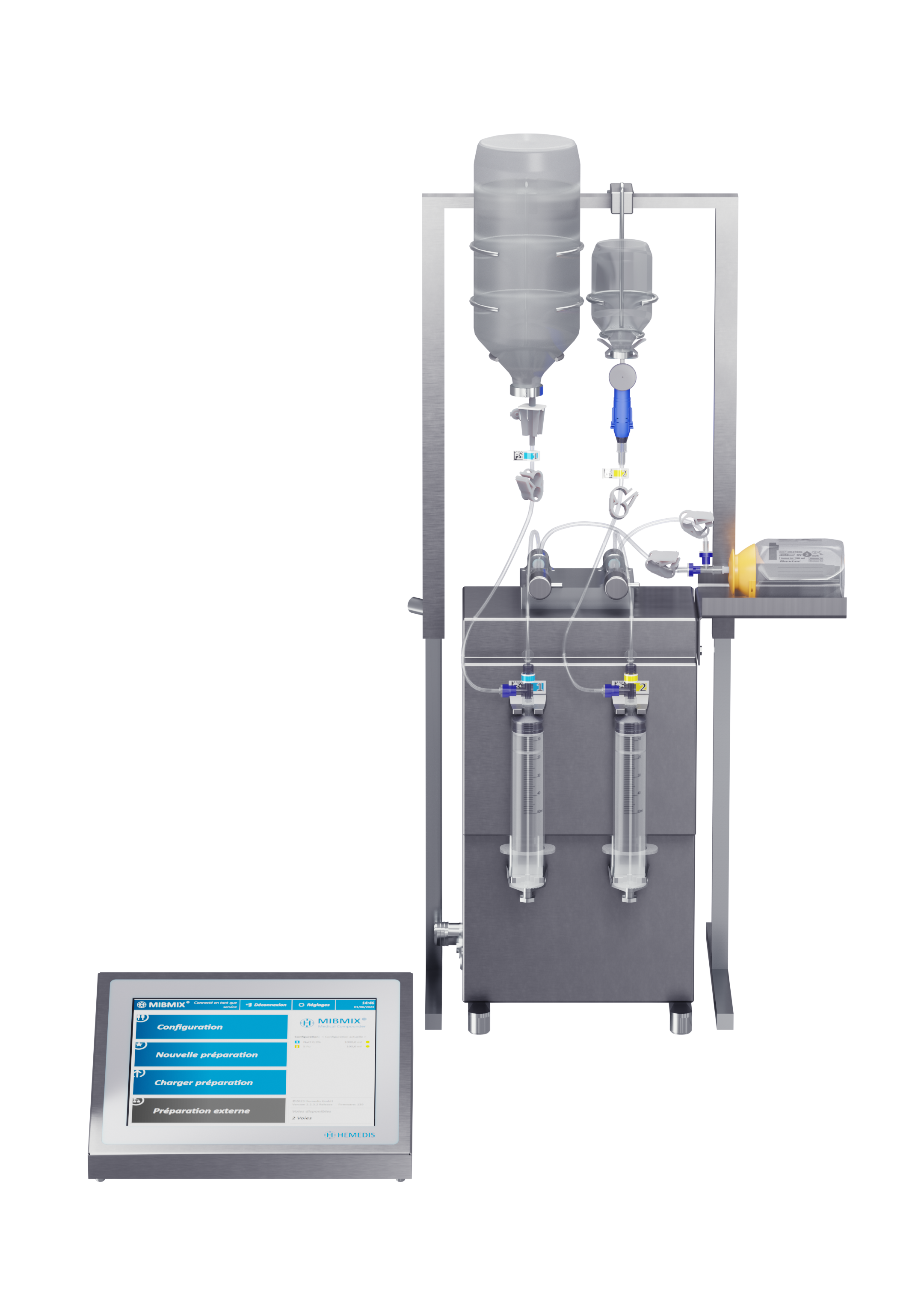

Product MIBMIX® C24 2-channel compounder for filling elastomeric infusion pumps ...

The MIBMIX® C24 2-channel compounder is a high-precision system for dosing and filling medical liquids under cleanroom conditions.

It can be used for patient specific production via an order entry software interface or batch preparation as a stand-alone device.

It is used where...

-

Product Brachytherapy cannulas

sfm medical devices gmbh offers wide range of products which includes brachytherapy cannulas. It belongs to oncology category. A cannula with excellent puncture values was developed, adapted to the respective seed size. Contact us for more information.

-

Product Isolator Technology

Safety and Performance from one source - with more than 25 years of experience. Isolator systems are becoming increasingly important to the pharmaceutical industry. Complex filling lines require competent management of the interaction between filling machine, isolator system and subsequent machines. C...

-

Product Bohle Conti Granulator BCG ®

L. B. Bohle Gmbh offers a wide range of process machines which includes bohle conti granulator bcg. It is a twin-screw extruder with a downstream dryer. Benefits: the monoblock design features no dead spaces or connections of it makes installation and cleaning easy and the torque measurement is particulary...

-

Product Microfluidizer technology

By using microfluidization technology process, Skyepharma provides solution to increase bioavailabity of poorly soluble APIs (micro and nanoparticule). It is also an interesting technology for micro and nano emulsion manufacturing.

-

Product Butyl Glovebox Gloves

The glovebox glove TRON 1000 is an excellent glove when working especially with polar hydrocarbons such as ketones, acids, esters, amine derivatives.

It also has a particular advantage with regard to its high gas impermeability.

Butyl offers high flexibility and a good sense of grip even at...

-

Product Continuous Microreaction Hydrogenation Platform

H-Flow series is built on the patented microreaction hydrogenation technology of Tsinghua University, which mixes highly pure hydrogen with continuously flowing reactants in a micropacked column loaded with catalysts and reacts. Combining automatic control of the whole process, inline real time measurem...

-

Product ROTOTHERM® MINI

The new Artisan ROTOTHERM® MINI thin-film evaporator offers continuous, scalable, and cost-effective separation. Research and development teams can benefit from this new technology preserving product quality, increasing throughput, and saving energy. This equipment has proven successful in drying and ...

-

Product JW extrude-spheroidizing pellets system

The process of machine is powder and dinder mixing to wet material, then to spheroidizing on the centrifugal dish, the pellsts can be got.

-

Product Butterfly valve mcv

American international container offers cleaning system which includes butterfly valve mcv. Feature: it is one of the best in the industry. Light weight and easy to use, manufacturers and processors around the world are relying on the müller containment valve to safeguard the health of their employees, whi...

-

Product Capacity 6000L Glass Lined Reactor with Motor, Agitator, Mechanical Seal...

1. Application:

Capacity 6000L Glass Lined Reactor With Motor,Agitator,Mechanical Seal Etc. is an ideal material for anti acid and alkali corrosion and its surface is very easy to Polish and no contamination to mediums. It's widely used in Petrochemicals, light

industry, pharmaceut...

-

Product PWD pilot filter/dryer

PWD pilot filter/dryer is designed to fit pilot scale testing with the functionalities of isolation (solid/liquid separation), washing and drying of specialty compounds (e.g. APIs, fine chemicals etc.). The filter has a filtration area of ca. 0.33m2 and a maximum chamber capacity of ca. 140liters, howe...

-

Product GPX1500 Vial

The Gasporox GPX1500 Vial represents a new approach to headspace oxygen gas inspection – fast, accurate, non-intrusive and non-destructive, in tubular vials.

The GPX1500 Vial is a very compact and easy to use instrument to measure accurate the headspace of pharmaceutical containers. Change over ...

-

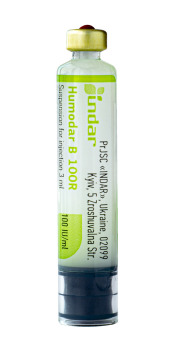

Product Humodar B 100R

PRJSC"Indar" provides wide range of insulin products in vials and cartridges which includes humodar b 100r. Its an anti-diabetic product of short effect. Ensures quick decrease of glucose level in the blood, intensifies its absorption by tissues. The effect starts after 30 minutes and can last within 5-7 h...

-

Product Pressure Spray Dryer

Pharmaceutical-grade Excellence:Our Pressure Spray Dryer is crafted for the pharmaceutical sector, ensuring drug stability and efficacy with unmatched moisture control.

Key Features: • Optimized Drying: Rapid, consistent drying via pressurized conditions. • Particle Precision: Supe...

-

Product Multi-inspection Platforms

With an increasing product portfolio and a variety of package types, sizes and formulations the requirements for processing and inspecting those products becomes more challenging. There is no test method that can do it all so that is why the combination of several methods is required. The VARIO MTX is a mo...

-

Product PRIMA Z syringe

Production lines for any requirement

Based on customer-specific product designs, a cycle time of 15 to 17 seconds can be achieved on the three currently available PRIMA Z production lines using the no-human-touch process. Ready-to-use syringes (Pre-Filled Syringes, PFS) according to ISO11040-6 w...

-

Product RoSS.SHIP: Cold Chain Shipping

RoSS.SHIP secures the cold chain storage and shipping of bulk drug substance for almost one week. With its Smart Tracking & Tracing Add-on you never loose control of your product.

Highly robust, stackable, coolable and compact – RoSS.SHIP cold chain shipping container is like Fort ...

-

Product Centrifuge

An industrial centrifuge is a machine that uses centrifugal force to separate components of a mixture based on their density or particle size. It consists of a rotating drum or bowl that contains the mixture to be separated, and the rotation creates a centrifugal force that pushes the components toward...

-

Product Soft bag Form-fill-Seal machine

Shinva provide the production line for Non-PVC soft bag Form-fill-seal machine, with different kinds of ports: like single hard port, double hard port, double tube, power-liquid double chamber, liquid-liquid multi-chamber soft bag.

-

Product Autoinjector Test System

The SA-41 and SA-61 automated autoinjector test system from Automationspartner ensures a precise product quality control and is easy to operate. The SA fulfills requirements by relevant authorities which state that combination products (autoinjectors) must be tested by the legal manufacturer prior to batch...

-

Product Integrated Granulation Line

Bowman & archer pharma machines (india) pvt.ltd provide a wide range of products which includes Integrated granulation. It is minimal floor area consumption for installation and quick product transfer & clean dust-free processing at reduced expenditure to improved operating & safety standards f...-comp245604.png)

-

Product DYNAMIC® BB

Multipurpose hose, flexible and light in weight. MTG DYNAMIC® BB combines a white PFA liner and white rubber food grade cover. Certifications: USP class VI, EU 10/2011, FDA and 3-A Sanitary Standards

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.jpg)