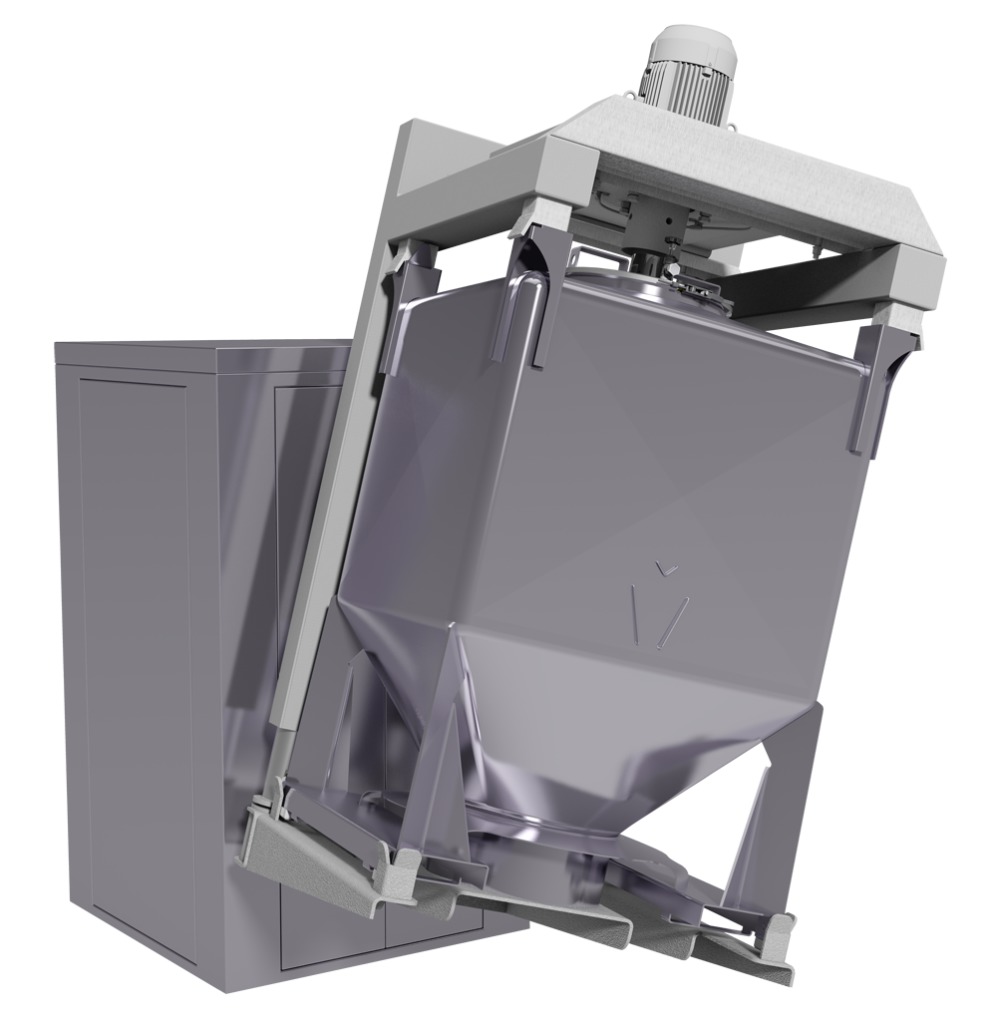

IBC-Bin Blender

Product Description

Matcon Limited

-

GB

-

2017On CPHI since

-

1Certificates

-

250 - 499Employees

Company types

Primary activities

Categories

Specifications

Matcon Limited

-

GB

-

2017On CPHI since

-

1Certificates

-

250 - 499Employees

Company types

Primary activities

More Products from Matcon Limited (2)

-

Product Intermediate Bulk Container (IBC) for handling tablets

Compared with boxes, kegs or drums, the Matcon Tablet Handling system significantly reduces time consuming and error prone manual activities. Using Matcon Tablet IBCs to transfer tablets and capsules between processes reduces the number of container movements and lowers labour requirements, whilst impr... -

Product Intermediate Bulk Container (IBC) for handling powders and granules

We offer a wide range of IBC sizes from 50 litres to 3500 litres to match system requirements. Smaller scale IBCs are ideal for processing small order sizes, whilst bigger batches are possible with the large scale IBCs.

The unique Cone Valve technology within each IBC prevents the tr...

Matcon Limited resources (1)

-

Whitepaper Whitepaper: Pharmaceutical Facility Design

The manufacture of pharmaceutical oral solid dosage (OSD) products is a crowded marketplace in which it can prove challenging to provide an ‘edge’ over competitors. Download the whitepaper below to find out how adopting lean, efficient manufacturing procedures particularly when specifying your building, can help.

Recommended Products

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance