- Home

- Foster Delivery Science

- Hot Melt Extrusion

CPHI Online is the largest global marketplace in the pharma ingredients industry

-

Products0

-

Companies0

-

Articles0

-

Events0

-

Webinars0

Hot Melt Extrusion

Product Description

Foster delivery science offers hot melt extrusion. It enhances solubility and bioavailability, lowers doses, and reduced production costs using solvent free processing.

Extrusion is also used to create novel dosage forms such as long term drug delivery implants and films.

Additional advantages of hot melt extrusion processing include: improved solubility, improved dispersion, improve stability, controlled release rates, volume and scale up flexibility, accommodation of various size molecules, taste enhancement, dose form and aesthetic flexibility. Contact us for more information.

Foster Delivery Science

-

US

-

2017On CPHI since

Categories

- Contract Development and Manufacturing Organisations (CDMOs) and Contract Manufacturing Organisations (CMOs) (Services) Contract Manufacturing

- Contract Development and Manufacturing Organisations (CDMOs) and Contract Manufacturing Organisations (CMOs) (Services) Contract Manufacturing of Dosage Form Drugs

- Finished Dosage Forms (Products) Parenterals

Specifications

- Selling PointsQuality Service

- Supplied fromUnited States

Sales Markets

- Middle East Region (e.g. UAE)

- Oceania

- North America (USA, Canada)

- Africa

- Central America (e.g. Mexico)

- East Asia (e.g. China, Japan, Korea)

- Europe - EU countries

- Europe - non EU (e.g. UK, Russia, ex-CIS countries)

- South America (e.g. Brazil, Colombia)

- South Asia (e.g. India, Pakistan, Sri Lanka)

- South East Asia (e.g. Thailand, Philippines, Singapore)

Foster Delivery Science

-

US

-

2017On CPHI since

Recommended Products

-

Product ADAPTEK® TECHNOLOGY

ADAPTEK® TECHNOLOGY is the general name for our 4 international patents and expertise in nanotechnology and controlled release systems.This is a transversal technology that allows to develop customized biopolymeric nanohydrogels, allowing the load with different API (drugs, vitamins, growth factors, etc.)....

-

Product Commercial Manufacturing

Quotient Sciences is a global player in commercial drug product manufacture of small molecule products for niche therapies including oncology and orphan drugs. Our commercial manufacturing facility located in Philadelphia is designed to handle your high-potency compounds.

Our commercial batch ...

-

Product Qualicaps® Hard two-piece capsules portfolio

Qualicaps® manufactures vegetal and animal origin capsules for a wide range of formulation types ranging from dry powders and pellets to pastes and liquids. We produce high-quality pharmaceutical-grade capsules and offer them in a wide range of sizes, colours, and printing options for your product to s...

-

Product Aseptic fill and finish

We offer solutions for companies that need CMO capacity concerning the aseptic filling of syringes and assembly and packaging of pre-filled syringes and auto-injectors. We will enhance your product by adding value through manufacturing if you require additional capacity or a complete technology transfer. q...

-

Product Sterile Injectables Contract Manufacturing

Pfizer CentreOne is a global leader in sterile injectables fill-finish.Count on us to carefully guide your compound from development through launch. We’re known for our expertise in: • Complex biologics • Controlled substances • Sterile suspensions • Lyophilization

You’ll be supported not on...

-

Product Sterile drug product CDMO services

Thermo Fisher Scientific's flexible aseptic manufacturing and sterile fill finish solutions for your molecule’s unique needs and challenges will enable success in early development, late-phase, and commercial manufacturing.

Thermo Fisher offers extensive sterile product development and commercial ...

-

Product Biorela® Total

Biorela® Total is a powerful polybiotic and a member of the strongest family of probiotics – Biorela®. The company Milsing has been developing strong products with clinically tested combinations of probiotic bacteria within the Biorela® line for 13 years. Biorela® Total is the latest addition to the portfo...

-

Product UV Light Blocking Tyvek Equipment Covers

UV Light Blocking Tyvek Equipment Covers are designed to keep cleaned pharmaceutical equipment and supplies clean and protected from external sources of contamination while also providing in-process protection to light sensitive biotech products.

-

Product Finished dosage forms

TABLETS /FILM-COATED TABLETS

• Batch size 100 – 600 kg

• OEB classes: 1 – 3

• Aqueous film coating

SUPPOSITORIES

•Batch size 100 – 450 kg

•Automatic filling into PVC / PE, PVC / PVDC / PE or aluminium foil

•Capacity of approx. 20,000 suppositories per hour

• Inli...

-

Product cGMP Manufacturing Services

Our Operations team has extensive experience in cGMP clinical drug product manufacturing. Our state-of-the-art facilities and cGMP compliant systems are specifically designed for quick-to-clinic operations. Eurofins CDMO’s team of Engineers, Technology Transfer specialists, and Scientists specialize in pro...

-

Product VetaFilmTM - Veterinary Oral Film Technology

VetaFilm™ is our proprietary veterinary oral film technology that provides significant market opportunities to improve drug delivery for companion animals. VetaFilm™ research and development services and veterinary oral films provide: • Dose placed directly on oral mucosa or on their f...

-

Product VELOXTAR™ technology

VELOXTAR™ is a technology that produces a very thin orally disintegrating tablet (ODT) like a coin. The distinctive tablet shape and unique formulation design allow the ODTs to disintegrate in 4-6 seconds. VELOXTAR™ technology significantly reduces the disintegration time, while still providing practical t...

-

Product Commercial packaging and labeling services

Packaging of solid dosage: We provide the primary packaging to final packaging service from granules(fine granules, powdered), tablets(Plain, Coated, Sugar-coated, Orally Disintegrating tables) and Hard capsules. Packaging features of solid dosage forms: (1)Double sided aluminum foil bliste... -

Product Lagaflex (Carisoprodol & Paracetamol) Tab

Lagaflex is a leading muscle relaxant - analgesic.

-

Product Contract manufacturing services for liquid herbal extracts

Pilot, small-, and mid-scale manufacturing of liquid herbal extracts including fill-and-finish, labeling, and shipping to customer`s site. Manufacturing documentation and certificates can be included.

Our integrated offering can include analytical testing, quality release, as well as product optimiz...

-

Product One-stop solutions by GEMÜ

GEMÜ is your one-stop shop for customized solutions. Advanced technologies have been integrated to meet the demand for complete solution providers in our markets. We offer our customers processes such as laser welding, printing through to completely assembled, tested, and packaged system solutions, as ...

-

Product HCG/Chorionic Gonadotrophin for Injection -OVIGIL HP 5,000 IU

The Gonadotropin That Delivers – Precision, Reliability & Consistency

This product is available as a combi pack of Chorionic Gonadotrophin for Injection BP 5000 IU & Sodium Chloride Injection BP 0.9% w/v (HCG Injection).

• Use: This highly purified Human Chorionic Gonadotropin...

-

Product Passionis

Passionis is a unique product specially for women, which have been related to sexual appetite boost properties, containing Liboost, Maca, Vitamin B6 and Zinc.

-

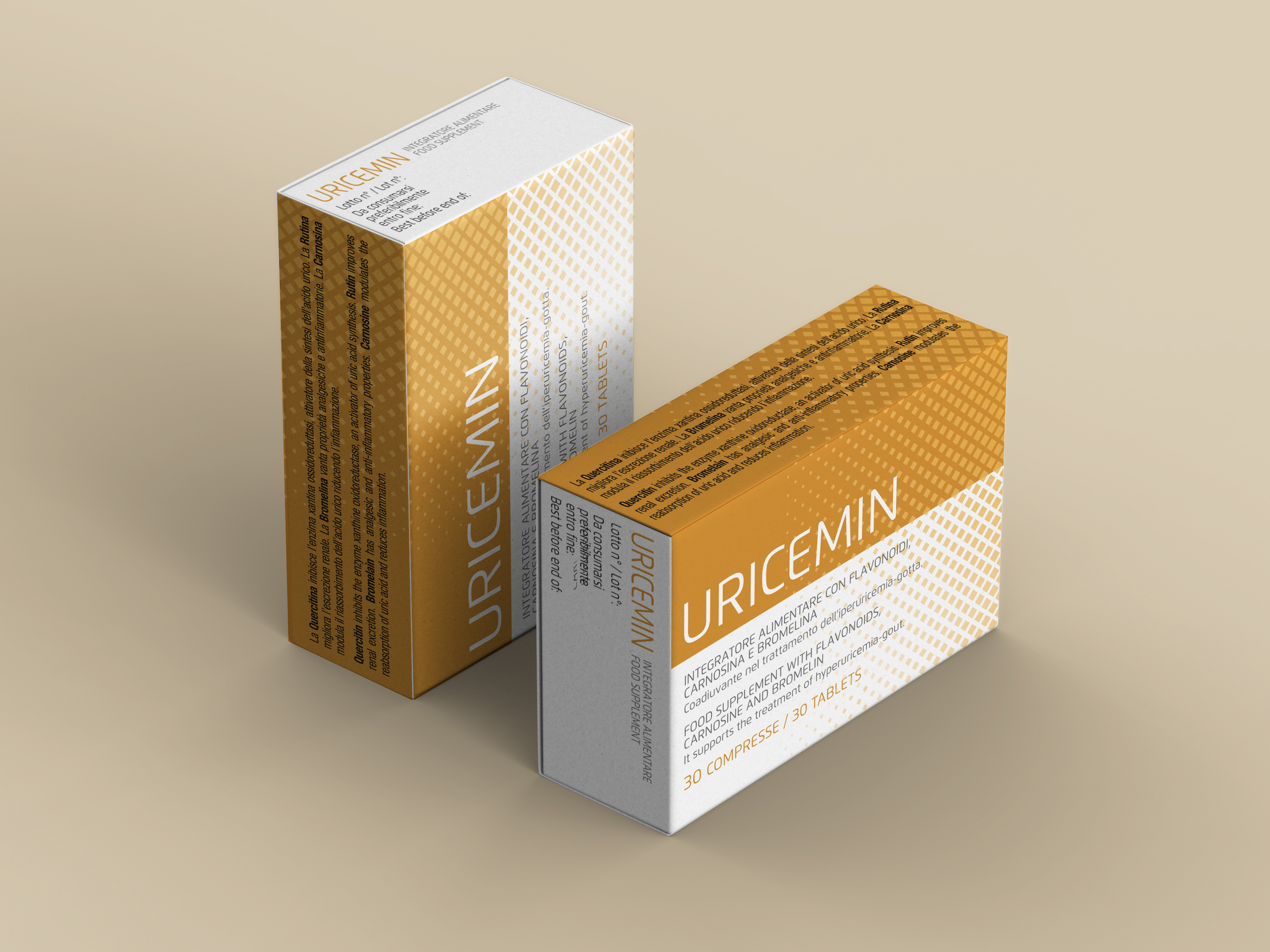

Product URICEMIN

FOOD SUPPLEMENT WITH FLAVONOIDS, CARNOSINE AND BROMELINSupports the treatment of hyperuricemia-gout

PRODUCT

The goal of our nutraceutical is to facilitate the dissolution of urate crystals and prevent their formation in patients with borderline uric acid levels.

INNOVATIVE FEATURES...

-

Product Solid & Liquid Dose Drug Manufacturing & Development

From OTC and Rx to diagnostics and dietary supplements, Avéma manufactures a full range of solid and liquid dose products, all manufactured under strict FDA guidelines and cGMP compliance. With an ever-growing portfolio of innovative formulas and a diverse mix of state-of-the-art equipment, our offerings a...

-

Product Water for Injection

Because diluent is as important as your API, Grifols offers you Water for Injection Drug Master File (DMF)

-

Product CDMO Best Practices from Benches to Batches - How to Transition from Cli...

What you need to seamlessly transition from clinical phases to commercial readiness.

Three unique abilities your CDMO must have to complete your project within your timeline are capability, flexibility and availability.

August Bioservices' Director of Customer Operations, Commercial Devel...

-

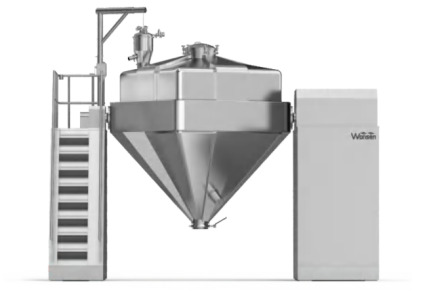

Product Blender

ApplicationIt can automatically complete lifting, clamping, mixing and descending tasks and can be matched with bins of different volume to meet the mixing requirement for large batches and diversified varieties of products.

Features • Changeable bins design for various capacity • Human/ machin...

-

Product Manufacturing & Commercialization

As a full-service CDMO, MedPharm provides comprehensive compounding, filling, packaging, serialization, and warehousing services for the commercial production of topical, transdermal, and transepithelial semisolid and liquid drug products. We also have dedicated suites designed specifically for the manufac...

-

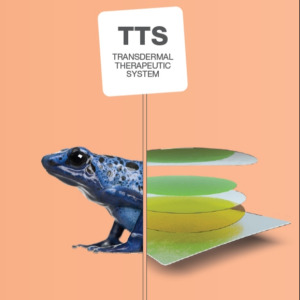

Product TTS - Transdermal Therapeutic System

Transdermal Therapeutic Systems (TTS) from LTS is a proven, yet flexible, ready to use platform designed to deliver a range of active substances.

TTS are pharmaceutical patches which are applied to the skin. The active substance enters into the bloodstream transdermally and acts where it's needed.

...

-

Product Manufacturing of complex and classic oral solid dosage forms

Manufacturing of classic and complex oral solid dosage forms: single layer tablets, multi-layer tablets, tab-in-tab, tab-in-caps, hard gel capsules, powder & pellets.

-

Product Tablet manufacturing services

Juniper Pharma Services has considerable amount of experience in formulating, developing and manufacturing a variety of tablet products. Its tablet manufacturing capability includes Immediate release tablets, Controlled-release tablets, Oro-dispersible tablets, Coated tablets and Mini-tabs. Contact us for ...

-

Product Contract Manufacture for Soft Gelatin Capsules

GAP specializes in soft caps technology since the mid 70s and has developed many products in soft capsules.With its cutting edge equipment serves as a CMO to numerous pharma companies in EU.

GAP as the capability to encapsulate under EuGMP, HACCP and Saudi FDA:

- pharma (R...

-

Product CTM production for nano and microparticle formulations

MJR PharmJet supplies CTM manufacturing services for your nano and microparticle solid and liquid formulations. We evaluate your product and process parameters in detail to ensure the comparability of products before and after CTM production. Furthermore we supply services at every step of technology ...

-

Product High Potent Manufacturing

Manufacturing site dedicated to OSD forms incorporating high potent APIs EOB 4/5 (OEL up to < 0.03 µg/m3).

Bluepharma has dedicated R&D centers and scale-up facilities that are well equipped in the formulation and pilot-scale equipment as well as analytics (covering a wide range of techniqu...

-

Product CDMO Services

Genovior is a dedicated CMO/CDMO, focusing on providing clients excellent, efficient, one stop services and solutions, from clinical trials (IND/NDA) to commercialization.

Our services include:

1. Process Development

2. Formulation Development

3. Analytical Development

...

-

Product Aenova CDMO Manufacturing Services INtro

With 15 production sites in Europe and the USA, the Aenova Group offers a broad range of dosage forms for Pharmaceutical and Consumer Health products. Our sites are equipped with the latest production technologies and have proven expertise to support your product needs with the highest quality and reliabil...

-

Product Specialized Parenteral Drug Services

Meeting the parenteral drug delivery challenge with Evonik. Polymer-based parenteral formulations taking extended release and targeted release further – advanced parenterals from small molecules to biopharmaceuticals - all bases covered. Lipid nanoparticle drug delivery technologies for oligon...

-

Product Sterile monodose cosmetics

At Neftis Laboratorios, we manufacture cosmetic products for third parties, including mesotherapy products. This beauty technique is one of the most widely used treatments for rejuvenating the face, fighting cellulite and eliminating localised fat. We have the latest technology at your disposal to create i...

-

Product KICK THE TICK® expert safe tick removel kit

KICK THE TICK® is a medical device intended for tick removal from human and animals bodies. It is recommended in the prevention of tick-borne diseases, including:

Lyme disease,

Tick - borne encephaliti,

Piroplasmosis.

Pat...

-

Product Aseptic Manufacturing

LLS Health takes a personalized approach to clinical and commercial aseptic filling.

We’re ready to fill a range of solutions and suspensions. Our FDA-ready, ISO 5 commercial filling line is qualified for 2 – 30 mL liquid solutions in vials, enabling quick-turn projects, and up to...-comp273426.jpg)

-

Product Betahistine 12.5 mg/ml Oral Drops

Glass bottle containing 100 ml oral solution with disposal pump. -

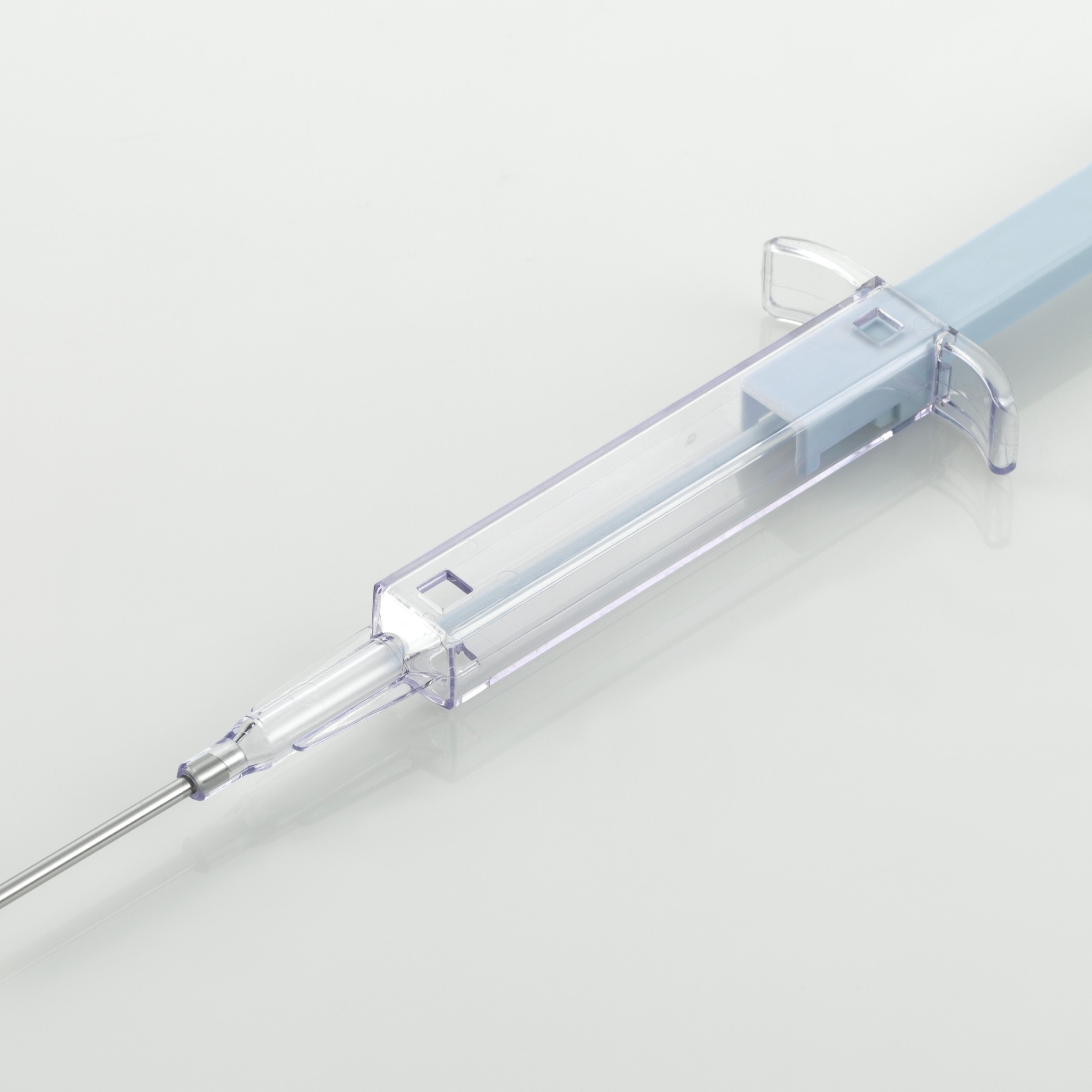

Product Implanters: Solutions for sustained released formulations

Implants are fragile and insertion into the body requires caution. Nemera developed a portfolio of devices to deliver implants with integrated needlestick protection. As implants can vary a lot, we support your projects and explore design attributes that will increase the user experience such as improved h...

-

Product CDMO

• Cytotoxic Injection (Liquid , Lyophilized) • ONCOLOGY • CYTOTOXIC API • EU GMP • JGMP (Japan) • KGMP (Korea) • PIC/S

-

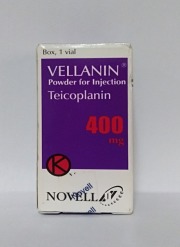

Product Vellanin

Indications

Potentially serious Gram positive infection

Contains Teicoplanin 400 mg

Package : Box of bottle 400 mg

-

Product MAG+ B6

Mag + B6 is a source of easily absorbed, organic form of magnesium and vitamin B6. They contribute to the reduction of fatigue and help in the proper functioning of the nervous system and in maintaining proper psychological functions. In addition, magnesium ensures proper muscles functioning, healthy bones...

-

Product Finished Dosage Form

modified-release tablets (MUPS and matrix tablets)film coated- or dispersible tabletsprinted tabletsmodified release capsulesmicro-tablets in capsulescontrolled substances & broad-spectrum antibioticssugar coated tablets

-

Product SNEC 30 - Self Nano Emulsifying Curcumin

The product SNEC30 (Self Nano Emulsifying Curcumin 30mg) is based on Indigenously developed drug delivery system for Curcumin by us in collaboration with Jamia Hamdard University and support from Department of Science and Technology, Government of India. We have been granted US Patent (US Patent No. US88...

-

Product Drug Delivery Devices - Pen injectors

In the pen injector product segment, our core competence lies both in high quality, reusable pen injectors and in economically produced disposable pens, including glass cartridges. Our many years of experience in the segment of „lancing devices and lancets" is especially advantageous here. We activel...

-

Product CRISPR Nucleases

In-Stock Products

Aldevron manufactures CRISPR nucleases, including SpyFi™ Cas9 Nuclease, SpCas9, SaCas9, Cas12a, and associated variants. The table below shows Aldevron's CRISPR nucleases that are available in two quality grades, from research-grade through cGMP.

Inventory CRISPR Nuc...

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.jpg)