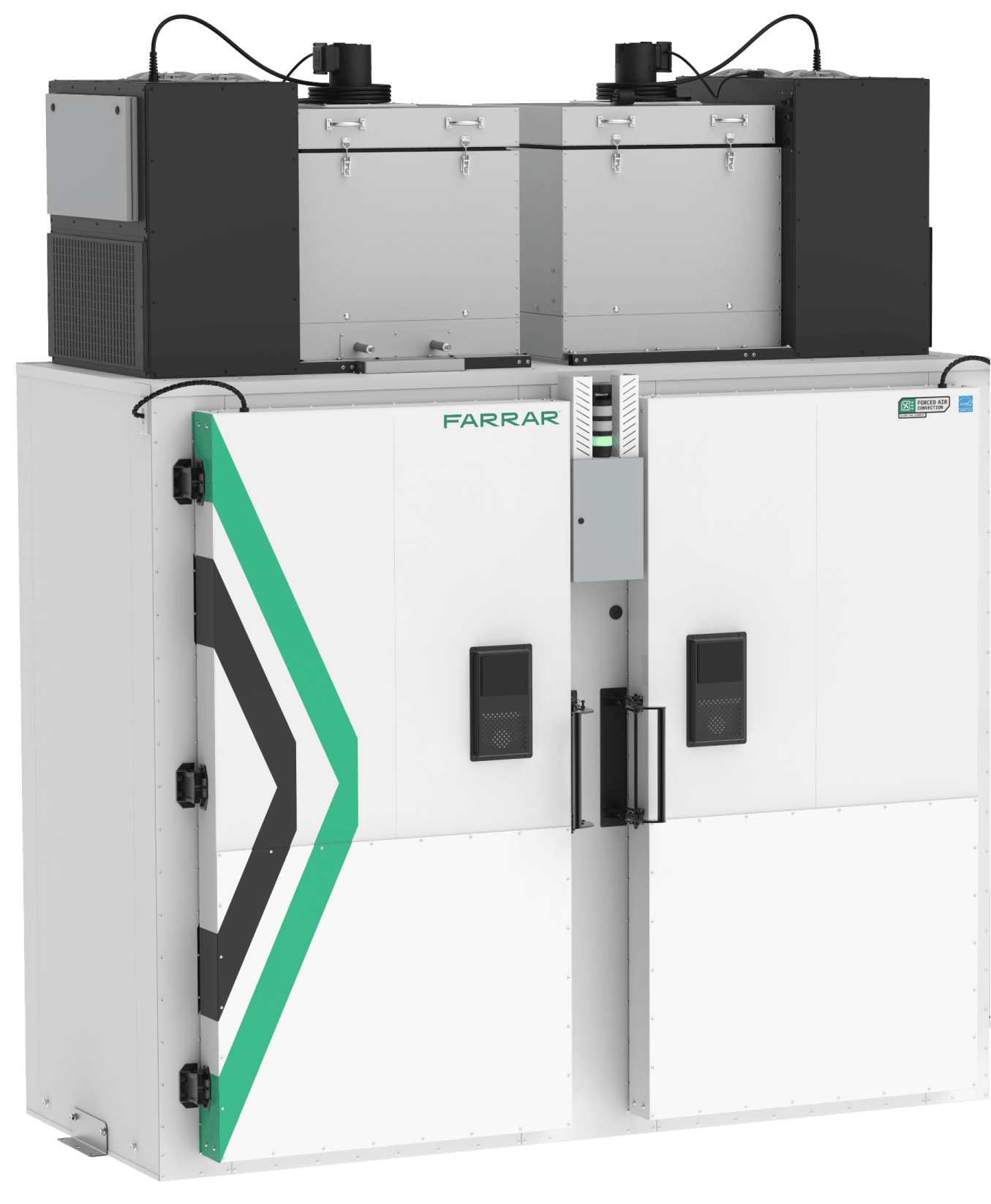

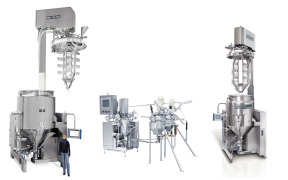

DYNO®-MILL UBM (Universal Bead Mill)

Product Description

Willy A Bachofen

-

CH

-

2017On CPHI since

-

100 - 249Employees

Company types

Categories

Willy A Bachofen

-

CH

-

2017On CPHI since

-

100 - 249Employees

Company types

More Products from Willy A Bachofen (3)

-

Product DYNO®-MILL KD

Grinding container volume of 6 to 600 liters.

The DYNO®-MILL KD is an agitator bead mill with horizontal grinding container. Specially designed agitator discs, mounted symmetrically on a shaft, transfer the energy required for wet milling and dispersion to the spherical grinding beads. An external pump ... -

Product DYNO®-MILL MULTI LAB

Grinding container volume of 0.15 to 1.4 liters.

For many decades, WAB has been the undisputed specialist in milling and fine dispersion technology with its world renowned DYNO®-MILL. The stringent requirements which the finished product has to fulfil also demand the highest standards of quality and abr... -

Product TURBULA®

Container volume of 0.1 to 55 liters.

The TURBULA® mixer is used for homogeneous mixing of powdery substances with different specific weights and particle sizes. Producing dry-to-wet and wet-to-wet mixtures is also possible.

The production process is hygienic and dust-free because the product is ...

Frequently Viewed Together

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

-comp248126.jpg)