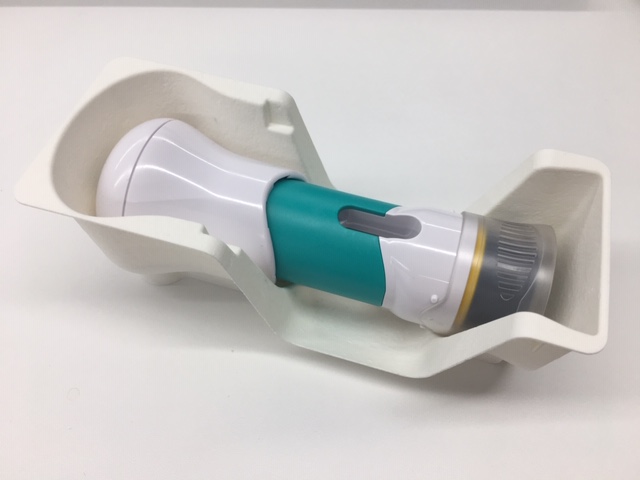

Device components made by Pulp-Injection

Product Description

Nissha Europe GmbH

-

DE

-

2023On CPHI since

-

5000+Employees

Company types

Primary activities

Categories

Specifications

Nissha Europe GmbH

-

DE

-

2023On CPHI since

-

5000+Employees

Company types

Primary activities

More Products from Nissha Europe GmbH (4)

-

Product Plunger rods made by Pulp-Injection

Customized plunger rods for syringes

Pulp-Injection molded products have similar features and functions as plastic parts, e.g. high rigidness and detailed design options.

Plunger rods made by Pulp-Injection are combinable with

other materials to ensure the function ... -

Product Winner of the Packaging Innovation Award 2024

Customized components for self-injection devices

Pulp-Injection molded products have similar features and functions as plastic parts, e.g. high rigidness and

detailed design options.

This cap won the Pharmapack Packaging Innovation

Award 2024

Components... -

Product Trays for autoinjectors made by Pulp-Injection

Customized trays, e.g. for self-injection devices

Pulp-Injection molded products have similar features and functions as plastic parts, e.g. high rigidness and

detailed design options.

The trays have dimensional accuracy and are stackable

to guarantee th... -

Product Customized closures made by Pulp-Injection

Customized closures made by Pulp-Injection

Pulp-Injection molded products have similar features and functions as plastic parts, e.g. high rigidness and

detailed design options.

The closures have dimensional accuracy to ensure

the closing as well as easy opening ...

Nissha Europe GmbH resources (3)

-

News Pharmapack Awards 2024 Packaging Innovation Award Winner – Nissha Europe GmbH

The 2024 Pharmapack Awards celebrated the best in innovation and design for the pharmaceutical packaging and drug delivery industry on January 24, 2024. -

News Pharmapack Awards 2024 - Celebrating Packaging and Drug Delivery Innovation

The 2024 Pharmapack Innovation Awards ceremony celebrated the best in pharmaceutical packaging and drug delivery innovation at all levels. The awards were held on January 24, 2024 at the Paris Expo Porte de Versailles.

Frequently Viewed Together

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

.png)

.png)