QbCon® 1 combines the three continuous processes of raw material dosing, twin-screw wet granulation and drying.

Continuous wet granulation and drying have long been a hot topic in pharmaceutical research and development (R&D) and industry. However, there is no truly continuous fluid-bed dryer on the market that is suitable for a long process time and that meets the quality requirements described in the present article. This article outlines the experimental testing on a new R&D system (QbCon® 1) for truly continuous granulation and drying. Special attention is paid to the dryer and the resulting granules.

The results show that very narrow and reproducible residence time distributions are achieved in the dryer, which leads to uniform drying of the granules of different size classes. The process delivers consistent quality regarding moisture and particle size of the granules over several hours. When changing the conveying speed of the granules in the dryer while maintaining all other parameters, it was possible to describe the limits for a fixed process/formulation combination, ...

L.B. Bohle Maschinen und Verfahren GmbH

-

DE

-

2015On CPHI since

-

1Certificates

-

250 - 499Employees

Other Content from L.B. Bohle Maschinen und Verfahren GmbH (5)

-

Brochure L.B. Bohle Product Profile for Your OSD Production

Learn more about our comprehensive equipment which enables the production of tablets from powder to the coated tabet via batch and continuous processing.

-

Whitepaper L.B. Bohle Coating Technology

L.B. Bohle has been the technological leader for all film coating applications for more than 15 years. Bohle Coaters guarantee excellent product processing with the highest profitability. We assert our leading role through continuous developments and patented advantages. Pharmaceutical Tablet Coating Processes Can be Divided into Three Basic Operations: MixingSprayingDrying Each step is carefully engineered and optimized to coordinate with the others. Bohle Coaters offer the best combination of the processing operations on the market. -

Whitepaper Bohle Fluid Bed System

Fluid bed equipment has been well known and established in the pharmaceutical industry for many years. Using a tangential fluid bed system represents state of the art technology in pharmaceutical manufacturing for particle coating, granulation and drying. With this in mind L.B. Bohle developed the Bohle Fluid Bed Systems with tangentially mounted spray nozzles and the Bohle Uni Cone BUC®. -

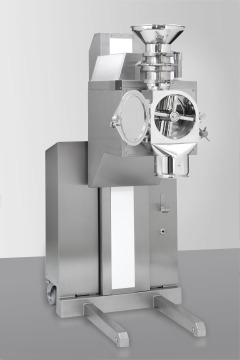

Whitepaper Current Trends in Sieving and Grinding Technology

The pharmaceutical production of tablets is practically unthinkable without the use of a sieve or a mill. These are needed whenever active and inactive materials are handled and tablets or other products are being manufactured. Sieving machines and mills are used for milling solids to reduce their size. This fulfils two purposes: Firstly, it enlarges the particle surface which increases the speed of dissolution. Secondly, it evens out differences between particle sizes to ensure that mixing can be homogeneous. Due to their versatility, milling and sieving machines play a crucial role in pharmaceutical production. They can be integrated into complex production lines, for example for filling/emptying or transfer operations at process machines, or for filling and decanting containers. -

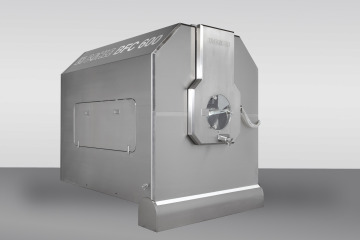

Whitepaper Containment applications for Dry Granulation and Film Coating

In the pharmaceutical industry, one term is becoming increasingly important: containment. It describes the process of containing a substance within a defined space, a method that is suitable for protecting operators and the environment in case of high toxicity and product reactivity. At the same time, containment prevents dust, gases or vapours from being released into the environment and contaminating the product.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance