Technical Data

31 Dec 2024

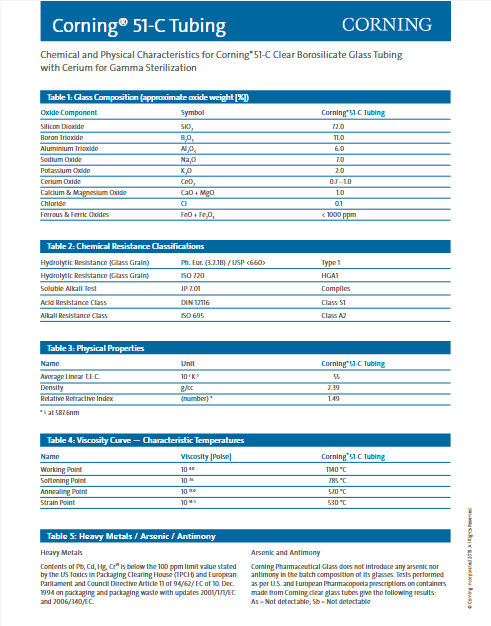

Corning® 51-C Tubing

PDF 1.4 MB

Chemical and Physical Characteristics for Corning® 51-C Clear Borosilicate Glass Tubing with Cerium for Gamma Sterilization

Content provided by our supplier

Corning Inc.

-

US

-

2015On CPHI since

-

5000+Employees

Company types

Primary activities

Other Content from Corning Inc. (13)

-

Brochure Corning Glass Tubing

Glass Composition & Chemical Resistance Classification, suited to supply high-quality clear and amber borosilicate glass tubing for pharmaceutical primary packaging -

Brochure Pharmaceutical Vial Tubing Specifications

Dimensional specification, visual quality specifications, and standard dimensions. -

Technical Data Corning® 33 Tubing

Chemical and Physical Characteristics for Corning® 33 Clear Borosilicate Glass Tubing -

Technical Data Corning® 51-A Tubing

Chemical and Physical Characteristics for Corning® 51-A Amber Borosilicate Glass Tubing -

Technical Data Corning® 51-D Tubing

Chemical and Physical Characteristics for Corning® 51-D Clear Borosilicate Glass Tubing. Formulated for closed end ampoules upon request -

Technical Data Corning® 51-L Tubing

Chemical and Physical Characteristics for Corning® 51-L Amber Borosilicate Glass Tubing -

Technical Data Corning® 51-V Tubing

Chemical and Physical Characteristics for Corning® 51-V Clear Borosilicate Glass Tubing -

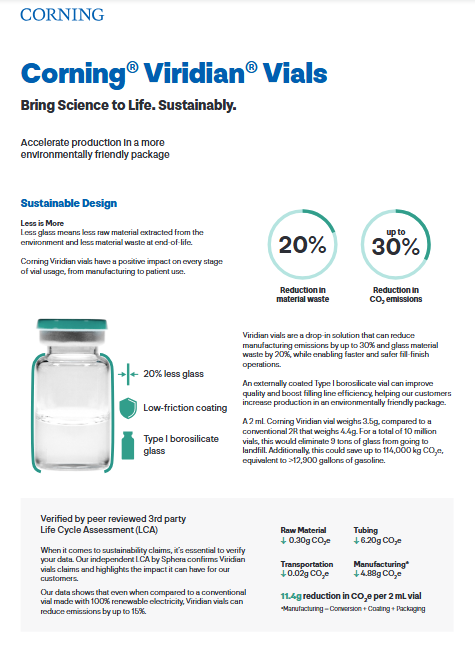

Brochure Corning® Viridian® Vials

Viridian vials are a drop-in solution that can reduce manufacturing emissions by up to 30% and glass material waste by 20%, while enabling faster and safer fill-finish operations. An externally coated Type I borosilicate vial can improve quality and boost filling line efficiency, helping our customers increase production in an environmentally friendly package. -

Brochure Corning® Velocity® Vials

Made with Type I borosilicate glass and coated with Corning’s proprietary low coefficient of friction (COF) technology, Corning® Velocity® vials can improve overall equipment effectiveness (OEE) by increasing filling line efficiency and yield, helping to reduce manufacturing costs and accelerate the delivery of critical pharmaceutical products. -

Brochure Corning® Valor® Vials

Valor Glass Product Benefits: • Eliminates delamination • Reduces glass particulate generation • Resists damage and breakage • Prevents* cracks • Enables higher throughput through smoother filling line operations • Decreases total cost of ownership

*In laboratory testing, Valor Glass vials provided at least 30x protection against cracks than conventional borosilicate glass vials -

Brochure Corning® Borosilicate RTU Vials

Corning® Borosilicate RTU Vials with SG EZ-fill® Technology

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance