Catalyx Functional Process Management

Product Description

Catalyx

-

BE

-

2023On CPHI since

-

500 - 999Employees

Company types

Primary activities

Catalyx

-

BE

-

2023On CPHI since

-

500 - 999Employees

Company types

Primary activities

More Products from Catalyx (2)

-

Product Catalyx Consulting Services

Our consulting services entails of strategic guidance from our experts who collaborate closely with your organization to understand your unique challenges and objectives. We enable our clients to evaluate their current processes, procedures, and overall operational efficiencies through a plant study. Follo... -

Product Catalyx Learning

In response to the global shortage of engineering skills, Catalyx designed several programmes to address the critical shortage of engineering skills in OSI PI and Delta V. The Skills Enhancement Programme is for experienced Engineers and is a cost-effective way to provide professionals, with hands on expe...

Catalyx resources (1)

-

Brochure Catalyx Digital LineClearance Assitant

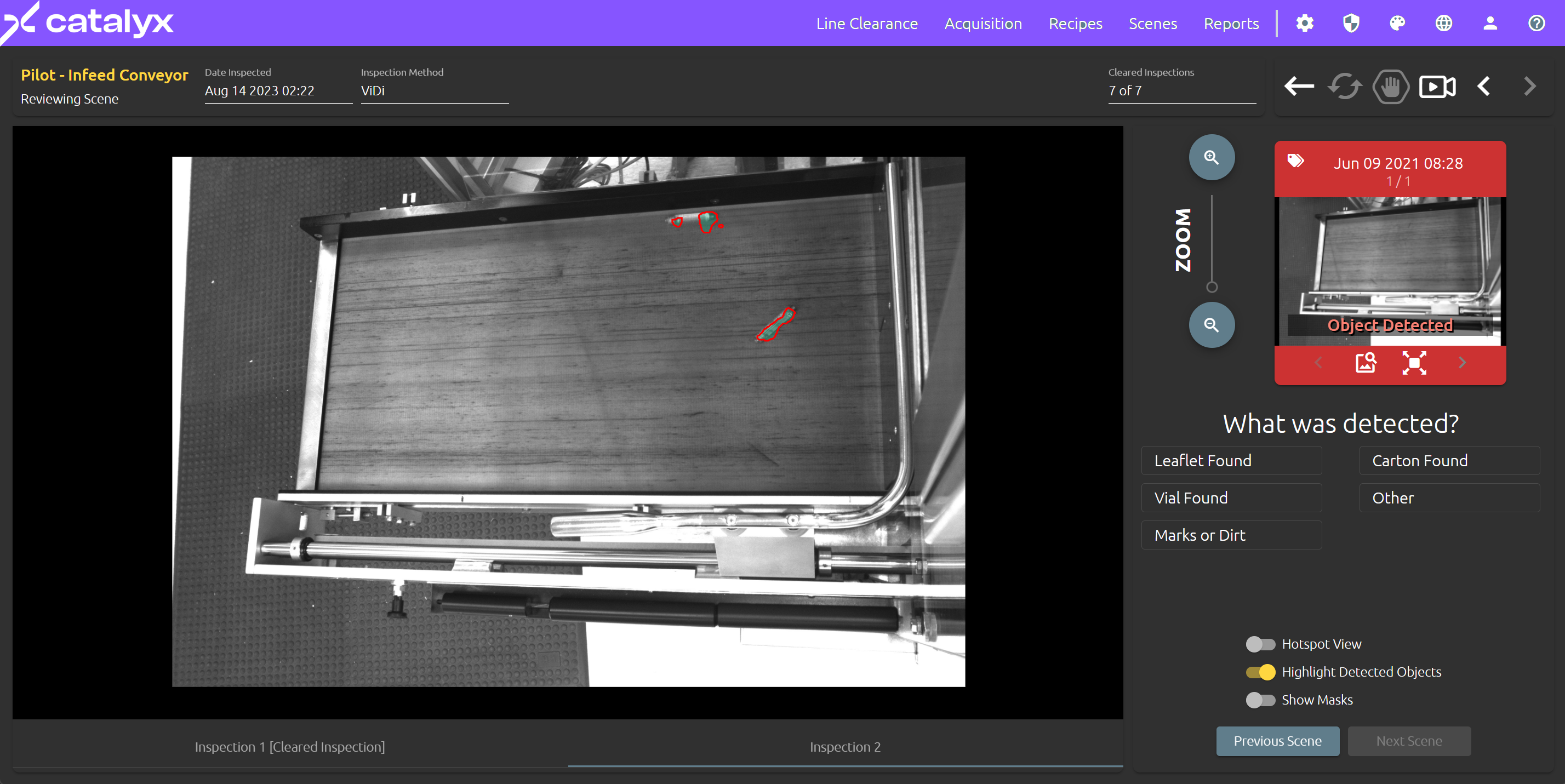

Digitally transforming the line clearance process to enable organizations in regulated industries to deliver products to market with maximum efficiency and quality. A multiple award-winning machine vision system which assesses the line clearance during line changeovers through objective electronic decisions that are quicker to achieve and repeatable when compared with manual line clearance procedures.

· Reduces inspection times by up to 85%

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance