Blister Thermoforming - Integra 520 - 520V

Product Description

Marchesini Group S.p.A.

-

IT

-

2017On CPHI since

-

1000 - 4999Employees

Company types

Categories

Specifications

Marchesini Group S.p.A.

-

IT

-

2017On CPHI since

-

1000 - 4999Employees

Company types

More Products from Marchesini Group S.p.A. (28)

-

Product Syringe Assembling - COMBI-3SD

The COMBI-3SD is an automatic, continuous motion machine for syringe plungering, labelling and insertion into a Safety Device.

The model COMBI-4SD can perform also the external labelling of the safety device.

For further information and technical details: https://www.... -

Product Vials Filling and Capping - STERY-SA

The STERY-SA is a rotary vial filling and stoppering machine suitable for Small Volume Parenteral (SVP) up to Large Volume vials (500ml) produced in aseptic condition, able to perform full or partial rubber stoppering for Liquid or Lyo products.

The alu-capping station can be integrated on b... -

Product Cartons Labelling - BL-A420 CW

Automatic labellers that feature an integrated checkweigher, for cartons dynamic weighing and checking.

As well as other similar models without the weighting feature, these machines are suitable to apply self-adhesive vignette and tamper evident seals on cartons, at high production speed. qq... -

Product Inspection for Glass Containers - RS1

The automatic inspection machine RS1 has been projected to integrate CMP's know-how and experience in camera based visual inspection and HVLD (High Voltage Leak Detection) system. The machine is equipped with 4 leak test stations and a rotation system in order to improve the quality of the inspection. ... -

Product Carton Labelling - SL-A 210

The SL-A 210 is a continuous motion machine suitable for 2D print&check and human readable information on the cartons, to apply two tamper-evident “TE” seals onto the two lateral flaps of the carton or as an alternative, to apply one vignette label on the top of the carton.

... -

Product Inspection for Glass Containers - SV

SV is the semi-automatic machine for the inspection of liquid and lyo products in ampoules, vials and cartridges or pre-filled syringes.The containers are automatically conveyed from the machine to the inspection station where the operator, looking at the containers, decides if accept or reject them. ... -

Product Blister Thermoforming - Integra 720 - 720V

Fully compliant with cGMP regulations with an ergonomic design that provides full accessibility to mechanisms and formaintenance (rear side), as well as a user-friendly working area at the front of the machine.

The blistering section passes the blister to the ROBOCOMBI, then its fast 3 axis ... -

Product Blister Thermoforming - MB Series

Machines designed to form blisters in PVC/ALU (if properly equipped, they can process different forming/lidding materials like ALU/ALU, Polypropylene, PET, PVC + Aclar®, COC).

These machines mold cavities into forming material, feed products of different shape into cavities ... -

Product Casepacking - Bestpocket

Automatic horizontal casepacking machine.

- Balcony construction for easy access, product visibility, maintenance and cleaning - Reliable and robust mechanical construction to reduce maintenance and prolong machine life - Compact-sized machine, with small footprint&nb... -

Product Counting Machine - Compact-12 Valida

Counting filling and capping monoblock machine for solids.

The COMPACT-12 VALIDA consists in a monobloc unit that integrates a variety of operations in just one machine, to guarantees very high levels of efficiency in the crucial counting, filling and capping phases.

Suitable ... -

Product Deep Draw Tray-Forming - FB Series

FB are mechanical intermittent motion fully automatic packaging machines, balcony construction, independent servo-driven stations, stainless steel finish, PC-controlled.Designed to fit into pharmaceutical-production environments, it thermoforms trays for vials, ampoules, syringes and similar products out o... -

Product Deep Draw Tray-Forming - Unica

Robotized packaging line integrating both operations of deep draw thermoforming and cartoning as well as both product and tray robotized feeding systems in a single monoblock. The whole line is controlled by a single, common display, and is characterized by a small footprint.

For further informa...

Marchesini Group S.p.A. resources (22)

-

News Press Release - EXTRA the new digital paltform by Marchesini Group

Marchesini Group presents EXTRA, the new digital platform that will enable clients to watch streamed events and visit the company remotely. Presentation in an exclusive location on 29 April. -

Video SA12J and COMBI 12 PL: Syringe Inspection, Labelling and Plungering - Teaser Machine

Complete Line for Syringe Inspection, Labelling and Plungering -

News Marchesini Group Press Kit 2020

With a turnover of 441 million Euro in 2019 and 2,000 employees in Italy and abroad, Marchesini Group is a flagship of the Packaging Valley in Emilia Romagna and one of the top four worldwide manufacturers of automatic pharmaceutical and cosmetic packaging machines. -

Video Cartoning Machine MA260 - Teaser Machine

Top quality continuous motion high speed horizontal cartoners.

Thanks to decades of experience in the field, these machines outline cutting-edge technologies in a compact layout with the highest safety features.

Main features:

- Versatility and efficiency in a small footprint

- Balcony design

- Oil-bath main drive units

- Synchronized servo motors

- Motorized adjustment of carton length quota

- User-friendly size changeover - Long carton magazine

- Cross control product-carton-leaflet -

Brochure Marchesini Group General Catalogue

Marchesini Group offers a wide range of Packaging Solutions, tailor-made for all products. -

Brochure Disposable Pre-Filled Syringes - Feeding, Handling & Assembling

The Marchesini Group combines Corima’s proven experience in disposable Pre-Filled Syringe (PFS) handling and assembling with the Group’s advanced technological robotic solutions,already firmly established in our packaging machines. This winning combination results in the development of new solutions aimed at maximising machinery performance, ease of cleaning and flexibility. -

Brochure Small Volume Parenteral Containers-Asceptic Processing

The Marchesini Group combines CO.RI.MA’s proven experience in machine production for sterile injectable products with the Group’s advanced technological robotic solutions, already firmly established in our packaging machines.This winning combination results in the development of new solutions aimed at improving Laminar Air Flow uniformity and the cleanability of the most critical areas of machinery in the aseptic process. -

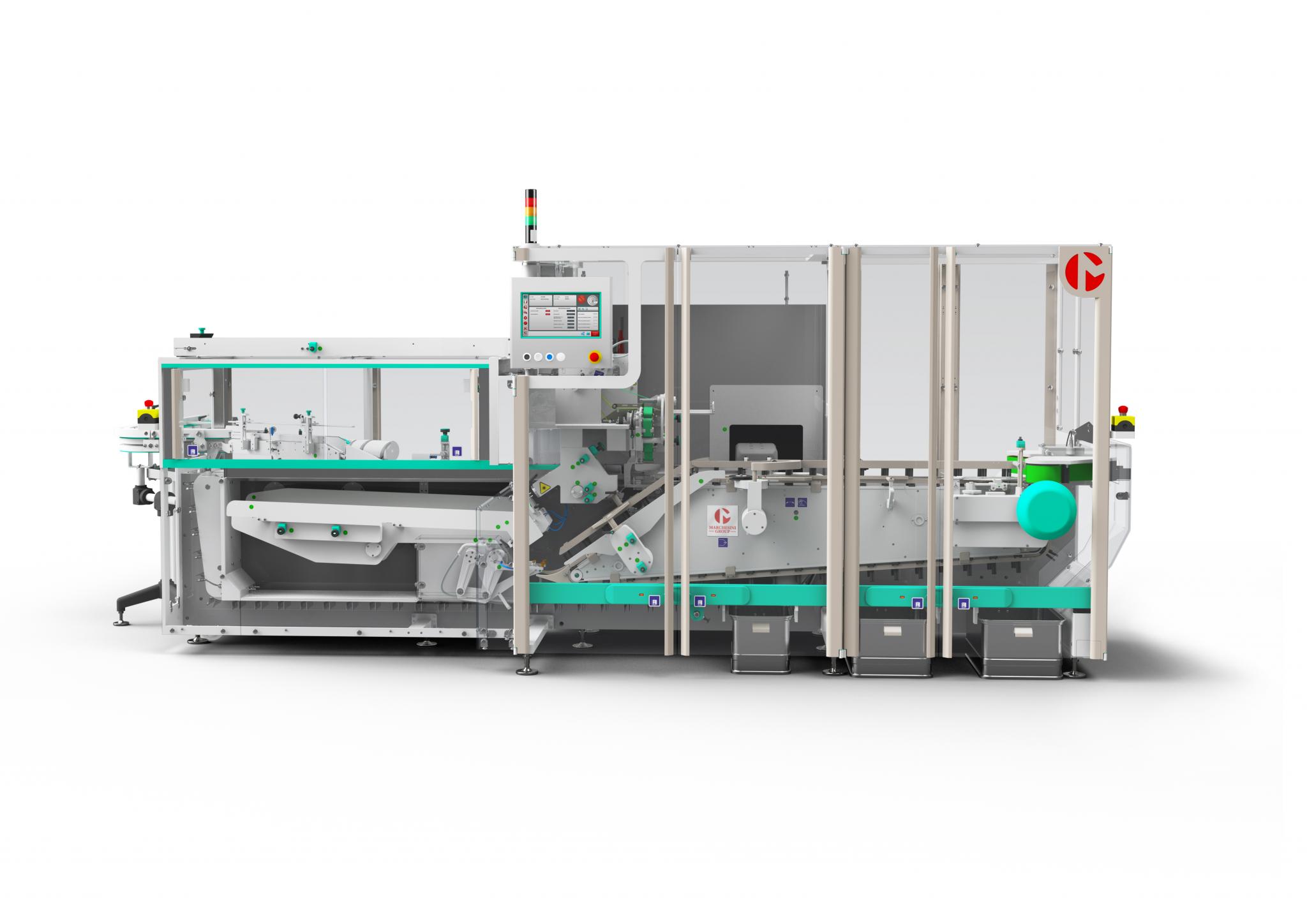

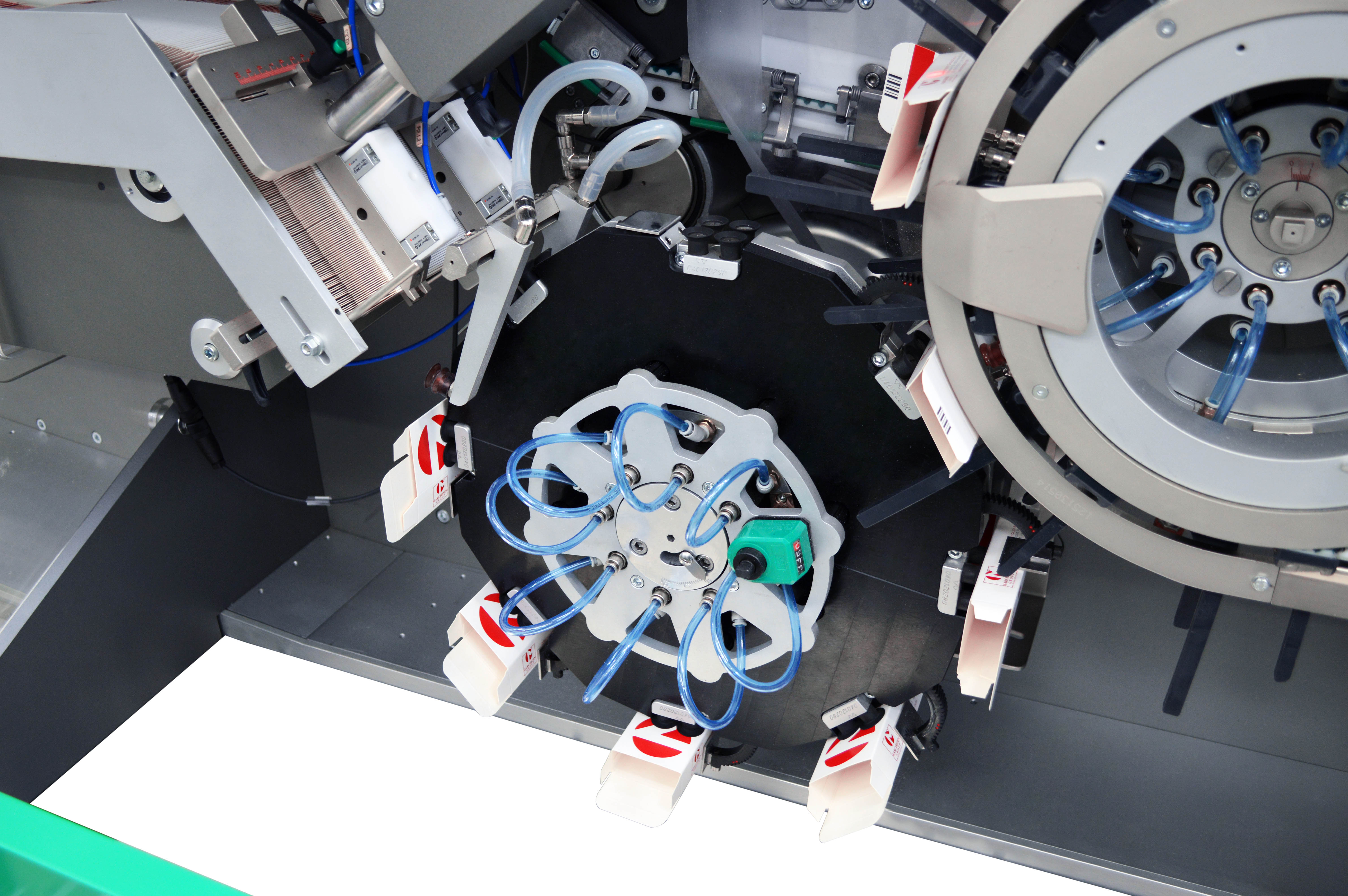

Video Extraordinary Solutions - Integra 520 V

Robotized Blister Line, integrating the two operations of blister thermoforming and packaging in carton, suitable to produce Blisters in PVC, PVCD, ACLAR (with dedicated devices). -

Video EXTRAFILL 10: filling and stoppering machine for syringes and vials

The EXTRAFILL 10 is an Automatic High-speed Filling Machine for nested syringes, capable of processing Ready To Use (RTU) Vials supplied into Nest/Tub or Nested-Trays, and RTU cartridges supplied into Tub/Nest. -

Video Syringe filling and assembling line

In 2019, we handed over a filling line for vaccines in syringes to an Italian Big Pharma. It was an extraordinary project inspired by three principles: high speed, quality and flexibility. The line is composed of an automatic debagging unit equipped with a pre-feeding conveyor for bagged tubs, that allows safe transfer of the sterile tub into the filling area. The second step is Tub opening, carried out by a robotized unit. Once the tub is open, it’s moved to the de-nester, whose function is to gently remove the syringes or vials from the nest and load them into the linear filling unit. Syringes are then moved to a re-nester which places the good syringes into their nest with no-glass-to-glass contact. -

Video Extraordinary Solutions

Underpinning the excellence that defines Marchesini Group is an artisan approach to the production of the key components of our automatic machines, both hardware and software, all of which are completely designed and produced in-house thanks to a workforce with multi-disciplinary technical know-how and expertise. This approach has enabled the Group to boost its leadership over the course of time, allowing it to dominate technological innovation in the sector and guarantee total customisation of every machine, tailored to the specific needs of each customer. -

Video EXTRA: the new digital platform by Marchesini Group

EXTRA: the new digital platform focuses on the needs of our customers and shows them the wide range of solutions we offer, through interactive technical insights and a live tour of our plants.

https://www.marchesini.com/en/extra -

Brochure Cartoners Catalogue

Determination, craftmanshipand Italian passion for product fine tailoring are what have always inspired Marchesini Group in meeting new challenges.

Today’s packaging industry is in continuous evolution and to keep up to speed with industry requirements, we constantly work alongside our customers to improve and excell in technological innovation. -

Video Vial Labeller and Trayloader: RL F500 and TM3 - Teaser Machine

Rotary Vial Labeller and Trayloader -

Video Complete Vaccine Packaging Lines: From Aseptic Filling to Secondary Packaging

This webinar originally aired as part of CPHI Discover - 17-28 May 2021 Overview of the 100% Aseptic Production Process EXTRAFILL 10: a focus on Marchesini Group's innovative filling and stoppering machine for syringes and vials Marchesini Group as pioneer in the world in creating complete lines for filling and packaging vaccines for the pharmaceutical industry The Group’s fast, reliable and high-precision machinery responding to all markets needs: standard and customized solutions

Frequently Viewed Together

Recently Visited

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance

-file108868.jpg)

-file116256.jpg)