Whitepaper

14 Sep 2022

How Controlled Freezing becomes Reality

PDF 751 kB

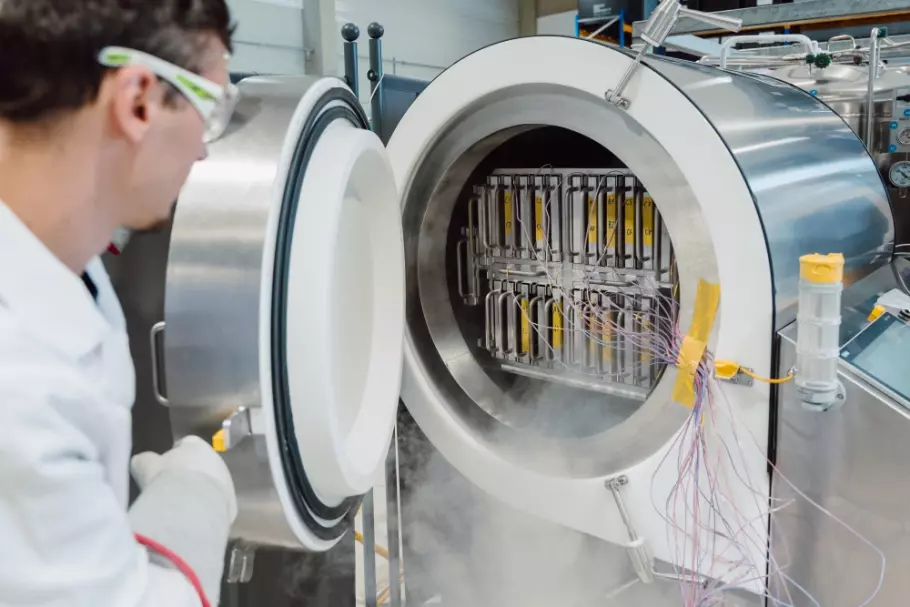

As one of the most essential parameters in terms of achieving control over freezing & thawing bulk, the freezing rate has been considered and evaluated in different tests. The leverage of the ice front growth speed had a significant impact on controllability and, as a result, on the protein quality.

Content provided by our supplier

Single Use Support GmbH

-

AT

-

2022On CPHI since

-

3Certificates

-

100 - 249Employees

Company types

Primary activities

Other Content from Single Use Support GmbH (9)

-

News Single Use Support in the midst of change in the healthcare industry

In the wake of the pandemic, the biotech industry is in a state of upheaval: more and more new drugs are being developed and produced. The Tyrolean company Single Use Support is actively involved in this process and continues to grow. -

Video IS YOUR FLUID FLOW ABOUT TO ERUPT?

Fluid management in laboratories is largely manual. Open manual fluid handling results in process variation, inaccuracy and increased risk of contamination. Aseptically closed systems are superior, ensuring reproducible and safe fluid flow. And prevent unexpected events.

More: https://www.susupport.com/applications/campaign-near-accident-filling -

News Novo Holdings Acquires Majority Stake in Single Use Support

The Danish company Novo Holdings has acquired a 60% majority stake in the Austrian-based company Single Use Support, thereby strengthening the company's further growth on a global level. -

Video HOW MANY MISSTEPS CAN YOU AFFORD?

Frozen single-use bags and assemblies can break if they are not properly protected. Watch your (process) step and prevent bags from breaking & contaminating your production facility. Smart secondary packaging can provide a robust & secure shell. You never know what could cause an avoidable misstep.

More: https://www.susupport.com/applications/campaign-near-accident-freezing -

News Single Use Support Opens US Office

Fluid and cold chain management expert Single Use Support has opened a subsidiary in Lexington, Massachusetts. Equipped with a product showroom, the office will also serve as a base for increased US staff. -

Whitepaper "Bestcellers": Controlled Filling Freezing of Cells

Advanced Fluid Management for Cell Culture Freezing, Cell Banking and Cell Therapy

Cells are important building blocks for today’s medicine and novel advanced therapies. FDA approvals for CAR-T cell therapies can be seen as proof for their ability to provide answers for many previously incurable diseases. The range of applications for cells utilized in the biopharmaceutical industry is very broad. The same is true for manufacturing processes for such therapies. The diversity of applications, be it for cell therapies, cell banking or cell culture suspension, adds to the complexity of cell-based manufacturing, which means that there is not a uniform fluid management process that applies to all cell-based suspensions. Sterile aliquotation into single-use bioprocess containers and freezing for cryopreservation of cells pose challenges for laboratories and manufacturers. -

News Controlled Freezing to -170°C: Single Use Support & SCHOTT Pharma Join Forces

SCHOTT Pharma AG & Co. KGaA and Single Use Support GmbH are joining forces to extensively test SCHOTT Pharma’s innovative solutions for the safe and efficient handling of small volumes of pharmaceuticals at ultra-low temperatures. -

News Sustainability Report: Commitment to Protecting Life and the Environment

Sustainability in Biopharmaceutical Fluid & Cold Chain Management -

Whitepaper Case Study: Reducing product loss when handling with single-use systems

A global biotechnology company produces different drug substances of highly valuables monoclonal antibodies (mABs). The company experienced a product loss rate between 0,5% and 5% due to the sensitivity of single-use bioprocess containers at sub-zero temperatures. Therefore, the goal was to reduce the current product loss below 0.5%.

This case study discloses how the implementation of RoSS® technologies from Single Use Support had an impact on the product loss during trials of hundreds of single-use bags.

You will be surprised of the cost savings due to reduced product loss.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance