Wiped-Film Stills & Evaporators

Product Description

Pope Scientific Inc.

-

US

-

2020On CPHI since

-

2Certificates

-

50 - 99Employees

Company types

Primary activities

Categories

Specifications

Pope Scientific Inc.

-

US

-

2020On CPHI since

-

2Certificates

-

50 - 99Employees

Company types

Primary activities

More Products from Pope Scientific Inc. (5)

-

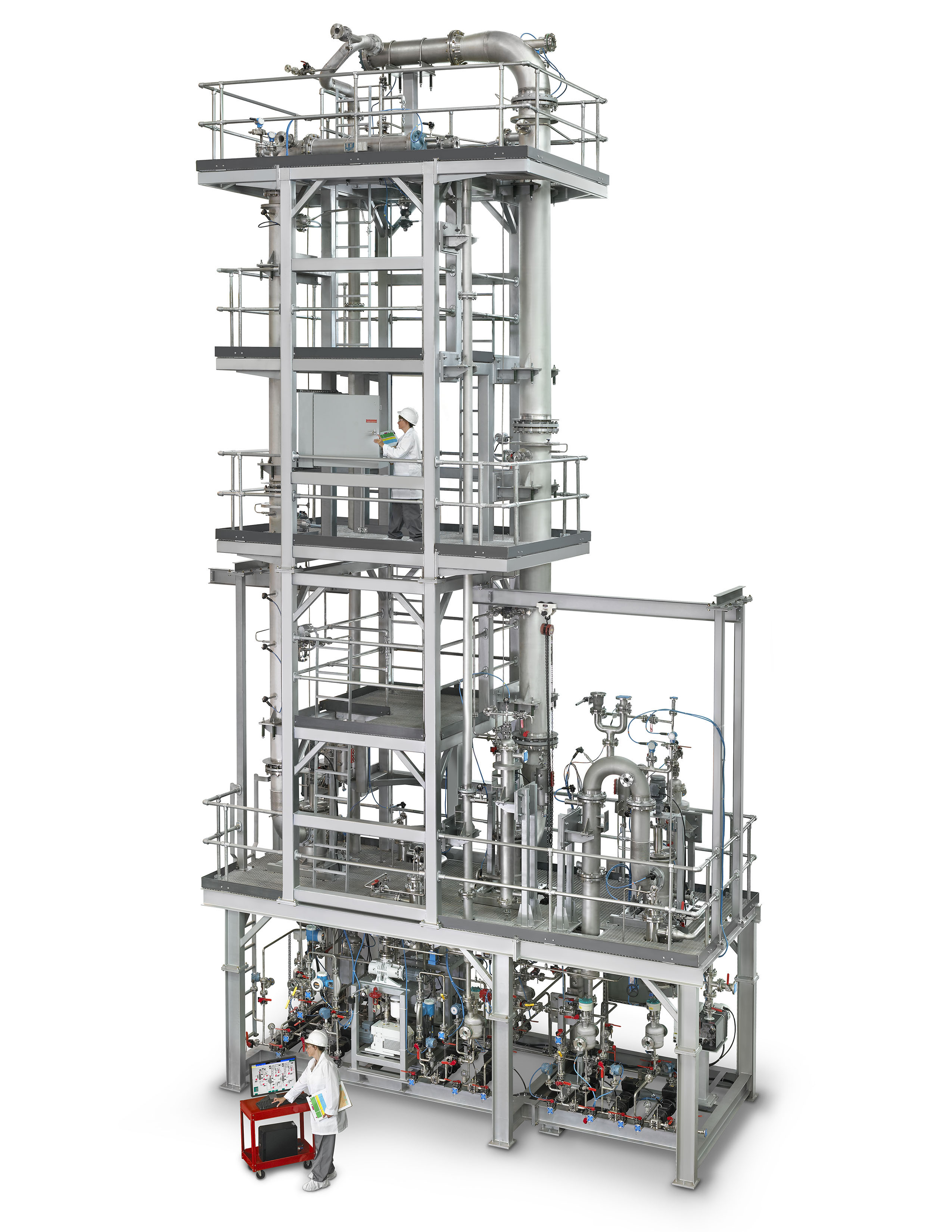

Product Hybrid Fractionating Column

Customized Hybrid Fractionating Column systems combine the multi-plate efficiency of fractional columns with the gentle reboiling effect of Wiped-Film Evaporators. This proven Hybrid technology allows the purification of heat-sensitive materials similar in volatility, which could not otherwise be separated... -

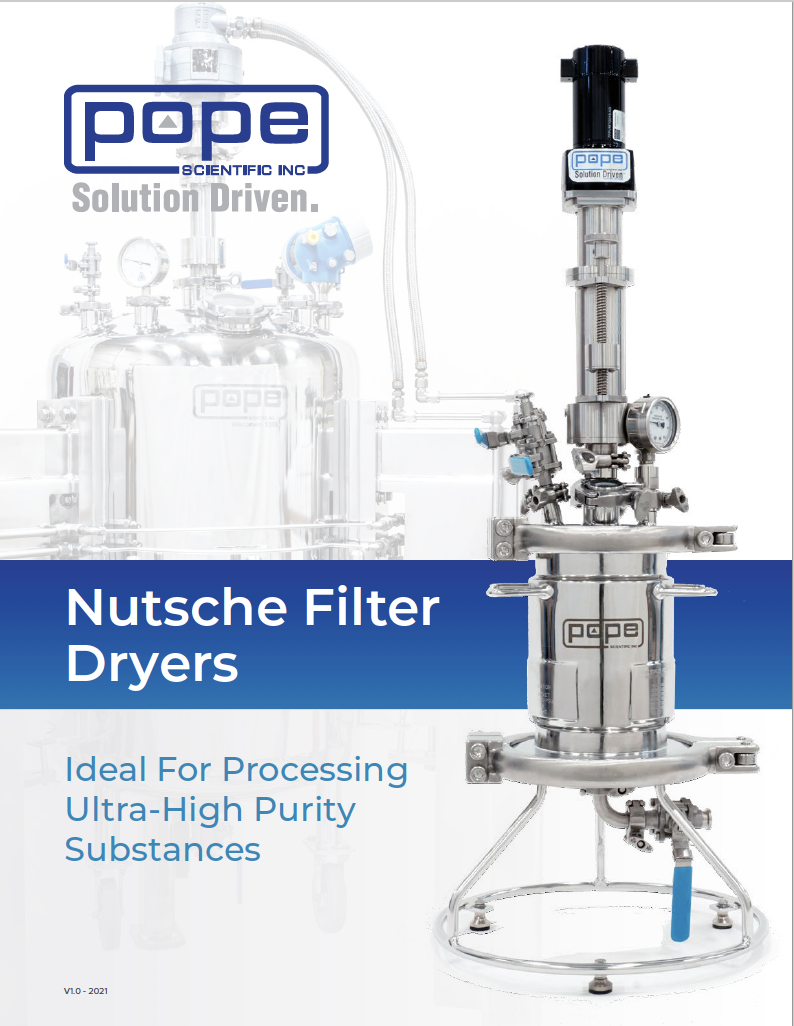

Product Nutsche Filter Dryer (ANFD)

IN STOCK - Pope nutsche filter-dryers are known and used worldwide for critical high purity separations of liquids and solids. Products include pharmaceuticals, bio-materials, electronics grade materials, fine specialty chemicals, and many others. Our nutsche filters are preferred for this separation, a cr... -

Product Process Vessels, Reactors and Process Systems

Stainless Steel Process VesselsSince 1975, Pope has provided stainless steel process vessels to industrial and academic research laboratories and industries of all kinds. Beginning with standardized pressure vessels for holding and dispersing solutions, Pope over the years, also offered special vessels, re... -

Product Turnkey Fractional Distillation Equipment - Batch Mode

The separation of volatile components (fractionation) can be achieved using Pope’s state-of-the-art line of fractional distillation equipment systems, (Fractional Columns). Fractional distillation is particularly suitable for critical applications that require separation of complex mixtures such as fine ch... -

Product Turnkey Fractional Distillation Equipment - Continuous Mode

The separation of volatile components (fractionation) can be achieved using Pope’s state-of-the-art line of fractional distillation equipment systems, (Fractional Columns). Fractional distillation is particularly suitable for critical applications that require separation of complex mixtures such as fine ch...

Pope Scientific Inc. resources (8)

-

News Pope Scientific to Launch WFC Series of CE Certified Wiped-Film Stills

Pope Scientific Inc., a prominent figure in processing technologies since 1963, proudly announces the launch of its CE-certified series of wiped-film still systems. Renowned for their efficiency and precision, these systems represent a significant advancement in distillation technology, adhering to the highest health, safety, and environmental standards set forth by the European Union.

The CE-certified series, comprised of Pope’s 2”, 4”, and 6” still sizes, bears the model designations WFC-200, WFC-400, and WFC-600 respectively. The first unveiling of the WFC-200 model will take place at ACHEMA 2024, showcasing Pope’s commitment to innovation and excellence in the field. -

Whitepaper Determining Which Fractional Distillation Process to Use: Batch or Continuous Mode

Distillation is an important method for the separation and purification of liquids in a wide range of industries and laboratories. Fractional stills often operate under pressure or vacuum and have a reflux device section for controlling and optimizing purity vs. throughput rate, however, these and several other topics of distillation equipment are not covered here. In this article, we will take a look at the two different types of fractional distillation; batch mode and continuous mode. -

News Custom Vessels & Processing Systems

Pope Vessels and integrated Processing systems are utilized in production, pilot plants and labs for processing pharmaceuticals, biomaterials, foods, specialty chemicals, etc.

-

Brochure Vessels, Reactors & Turnkey Processing Systems

Pope Scientific offers a wide variety of stainless-steel portable pressure vessels,

reactors, blenders, and fully turnkey processing systems. Our portable pressure

vessels are all manufactured, certified and permanently stamped according to

ASME Section VIII requirements to ensure safety. They are available in a wide array

of sizes, finishes and additional customizable options.

For unique applications, traditional and highly customized reactors are offered, as

well as fermenters, dispensers, mixing or homogenizing units, hydrogenators, evaporators,

distilling boiling pots, and other dedicated or general use vessel systems.

We also offer complete, custom processing systems for clients. These systems

often incorporate many items peripheral to a process vessel or reactor, including

additional vessels, filter systems, chillers, heaters, pumps, heat exchangers,

condensers, load cells, powered lifts, vacuum systems, fractionating columns and

other components, as well as recorders, controls or computer/PLC control systems.

Skid mounting or portable heavy carts are offered.

Pope’s experienced application specialists are available to discuss specific

requirements and engineer a total solution for your unique application. Contact

us today to discuss your needs and discover what options we can offer.

-

News Pope Scientific expands scope of offerings for Nutsche Filter-Dryer sizes, designs and systems

Increased range of sizes and available features, plus new options in ANFD systems and the popular Benchtop Nutsche Filter for scaleup and kilogram level production -

Video Pope Scientific Nutsche Filter Dryer Overview Video

In this video, Ben provides a high-level overview of what Pope's Nutsche Filter-Dryers are, and how they are utilized in lab, pilot plant, and production scale separations. For more information visit: https://www.popeinc.com/latest-news/video-nutsche-filter-dryer-overview/ -

Video Pope Scientific Company Overview & Capabilities

Take a closer look at Pope's capabilities, products, people and facility. We've been at the forefront of manufacturing chemical processing equipment, engineered systems and laboratory apparatus for science and industry for over 50 years. We are Solution Driven – Our long history demonstrates how clients have brought routine and complex separation/purification/mixing applications to us to make their solutions a reality. -

Brochure Pope Scientific Nutsche Filter Dryer Product Overview

This brochure provides an overview of how Nutsche Filter-Dryers work and the different specifications and design features that can be customized depending on your application. Ideal For Processing Ultra-High Purity SubstancesPope nutsche filter-dryers (also known as ANFD) are known and used worldwide for critical high purity separations of liquids and solids. Products include pharmaceuticals, bio-materials, electronics grade materials, fine specialty chemicals, and many others.

Position your company at the heart of the global Pharma industry with a CPHI Online membership

-

Your products and solutions visible to thousands of visitors within the largest Pharma marketplace

-

Generate high-quality, engaged leads for your business, all year round

-

Promote your business as the industry’s thought-leader by hosting your reports, brochures and videos within your profile

-

Your company’s profile boosted at all participating CPHI events

-

An easy-to-use platform with a detailed dashboard showing your leads and performance